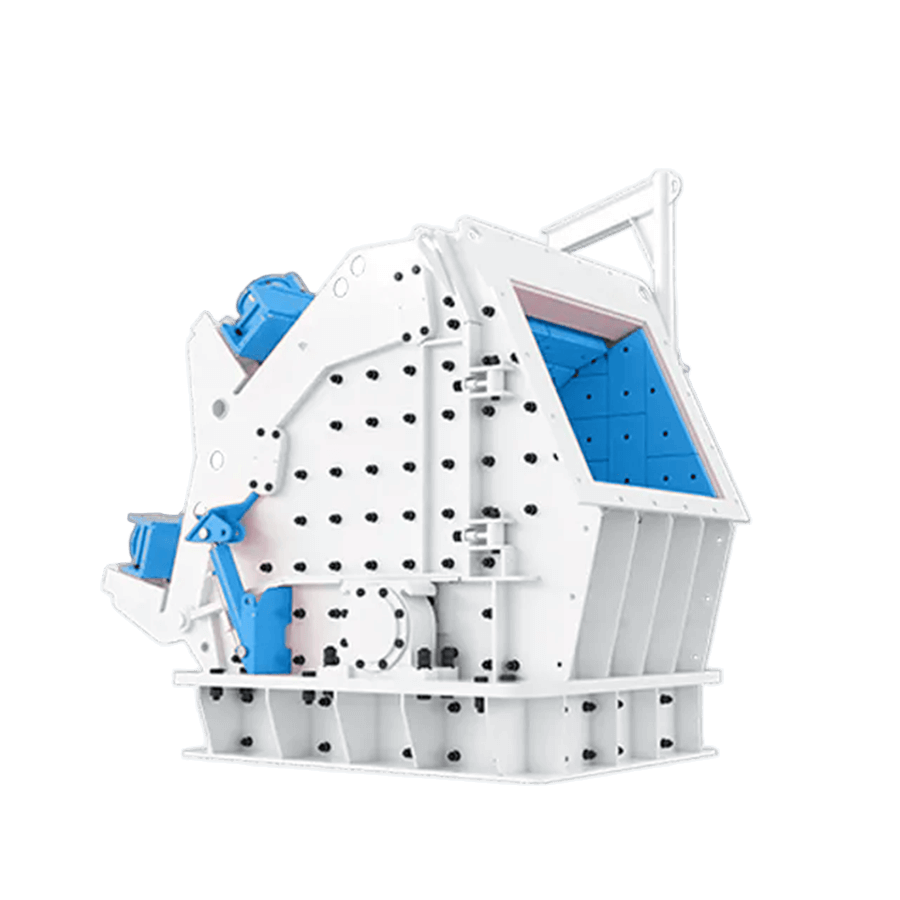

Impact Crusher For Sale

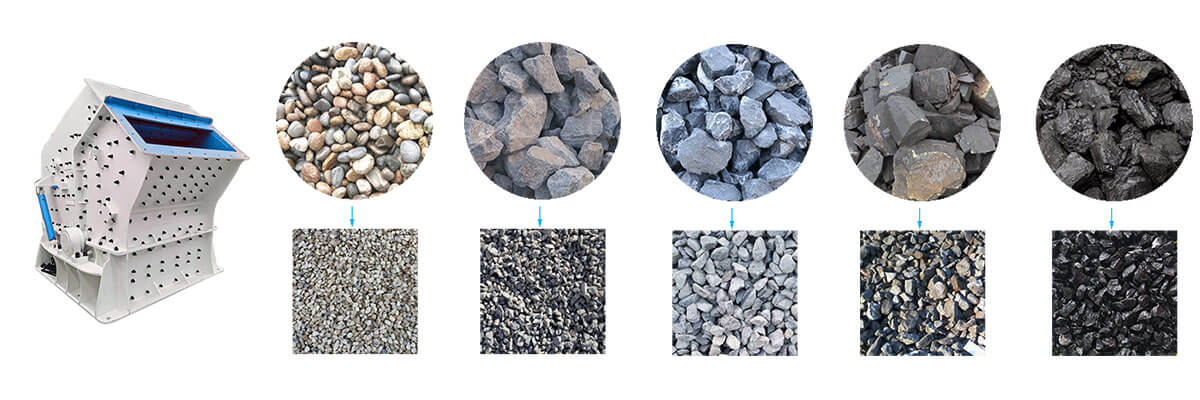

Applicable materials:

Iron ore, copper ore, gold ore, phosphate ore, silica ore, gypsum, granite, basalt, limestone, marble, quartz, pebbles, concrete blocks, bricks, waste brick slag, etc.

Feeding size: 1-1300 mm

Power: 45-1200 Kw

Capcity: 15-2000 T/h

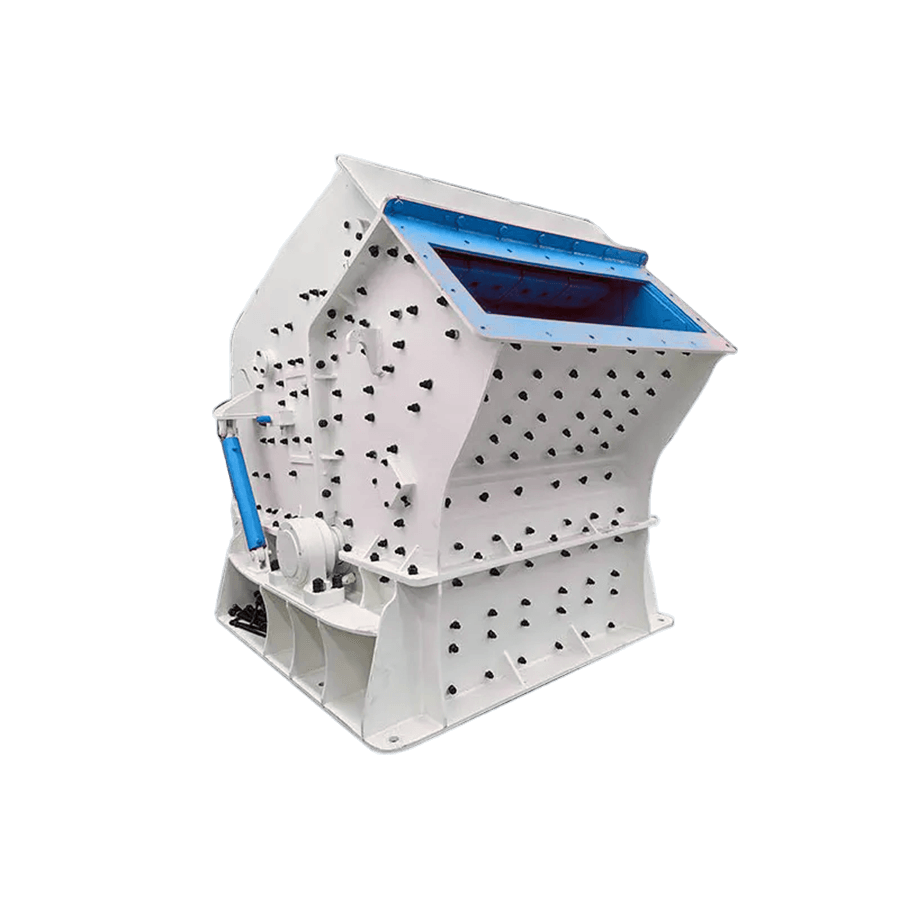

What is a impact crusher

The impact crusher is a highly efficient medium and fine crushing equipment widely used in mining, construction, highways, and railways. It is suitable for processing medium-hard materials (≤350MPa compressive strength) such as limestone, granite, and basalt. Featuring a large crushing ratio, excellent product shape, and low energy consumption, it is ideal for producing high-quality aggregates.

Types of impact Crusher We Sale

The impact crushers produced by Henan Reacore can be divided into PF series impact crushers and RS European version impact crushers. This machine is mainly used for medium and fine crushing processes in various sand and gravel crushing lines, and the output particle shape is good.

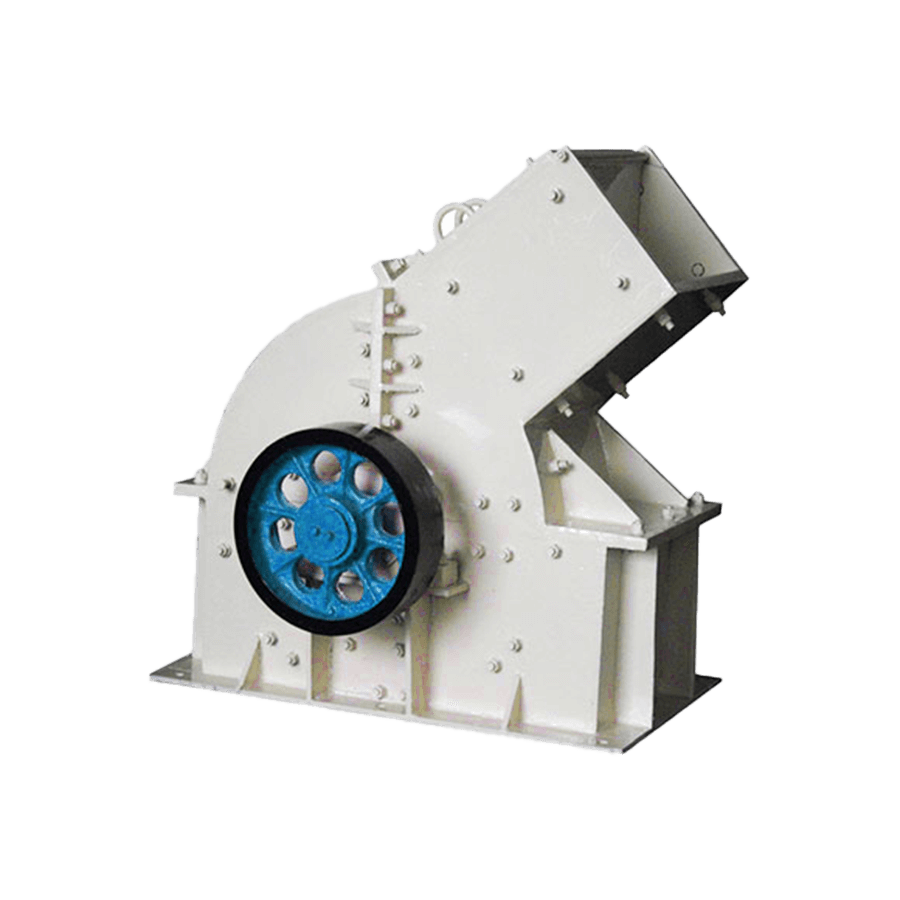

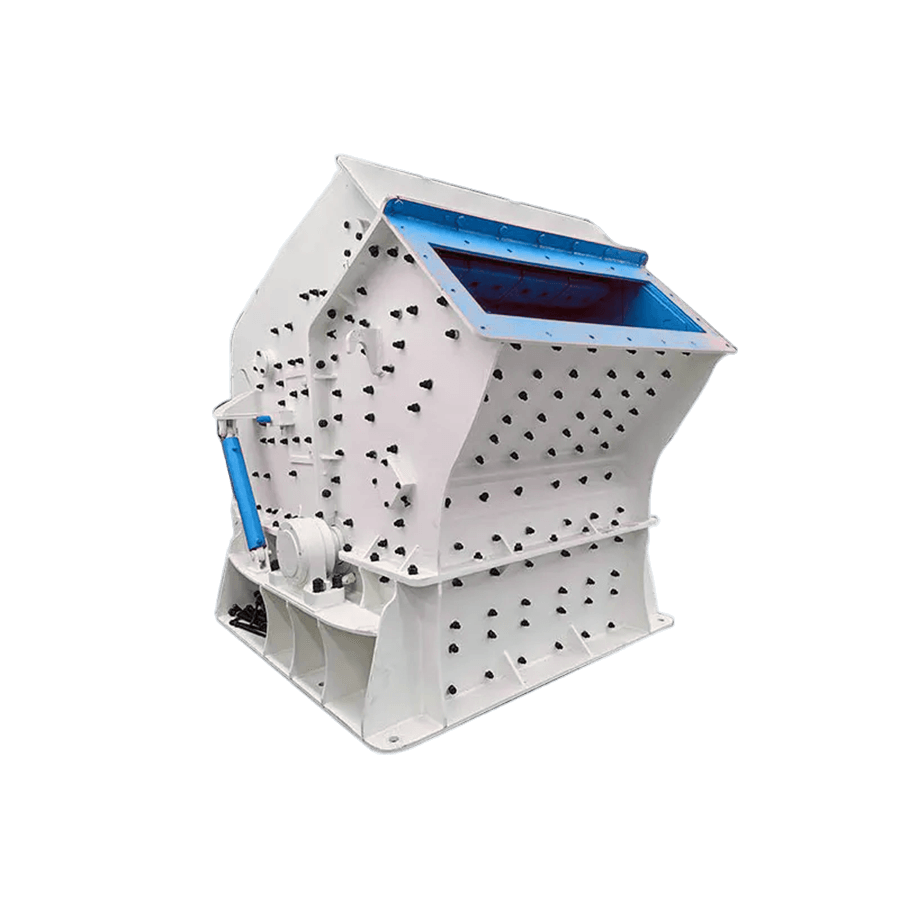

PF Impact Crusher

PF impact crusher adopts the principle of impact crushing, so that the material forms relatively regular cubic particles during the crushing process. The needle-like content is low and the product particle size is uniform. The feed size is 1-700mm and the capacity is 15-800t/h.

PF Impact Crusher

Henan Reacore’s PF series impact crusher optimizes the crushing chamber and rotor design, greatly increasing the processing capacity.

Capacity: 1-800 t/h

Feeding size: 1-700 mm

Voltage:220v/380v/415v/440v/480v

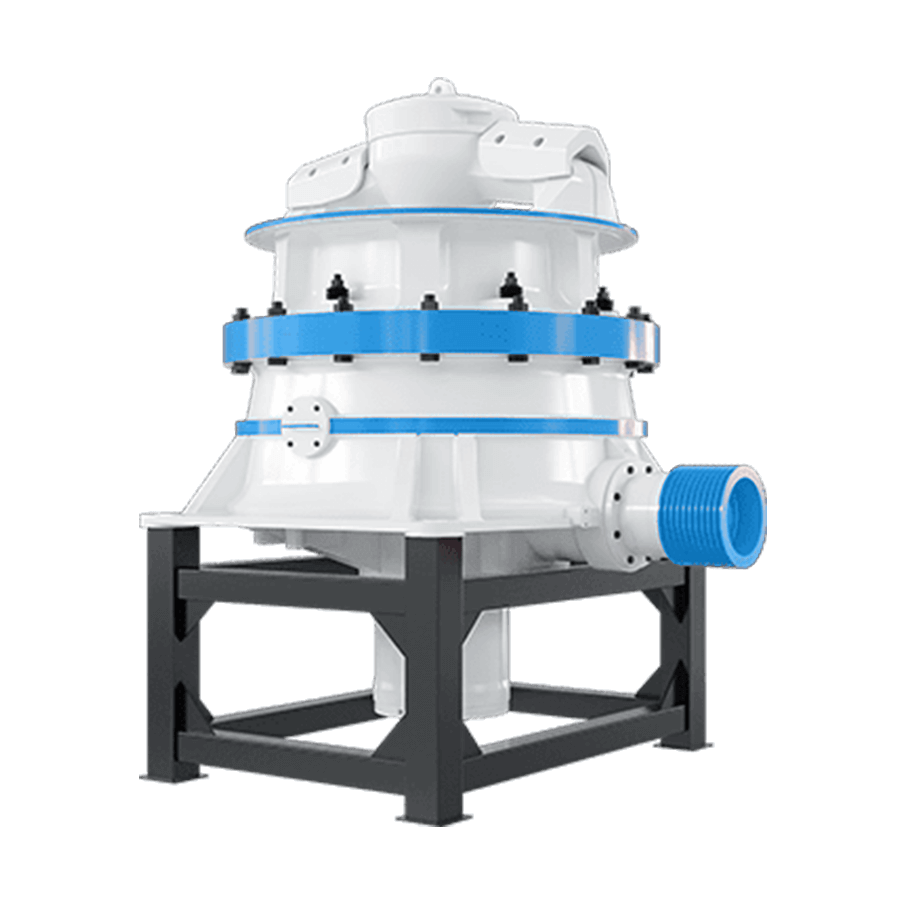

RS European impact crusher

The PE series jaw crusher produced by Henan Reacore is widely used in primary crushing in mining, construction, metallurgy and other industries. The capacity can reach 1-800t/h and the feed force is less than 1000mm.

RS European impact crusher

The RS European version jaw crusher produced by Henan Reacore has a large crushing ratio and the finished material is in cube form.

Capacity: 250-2000 t/h

Feeding size: 1-1300 mm

Voltage:220v/380v/415v/440v/480v

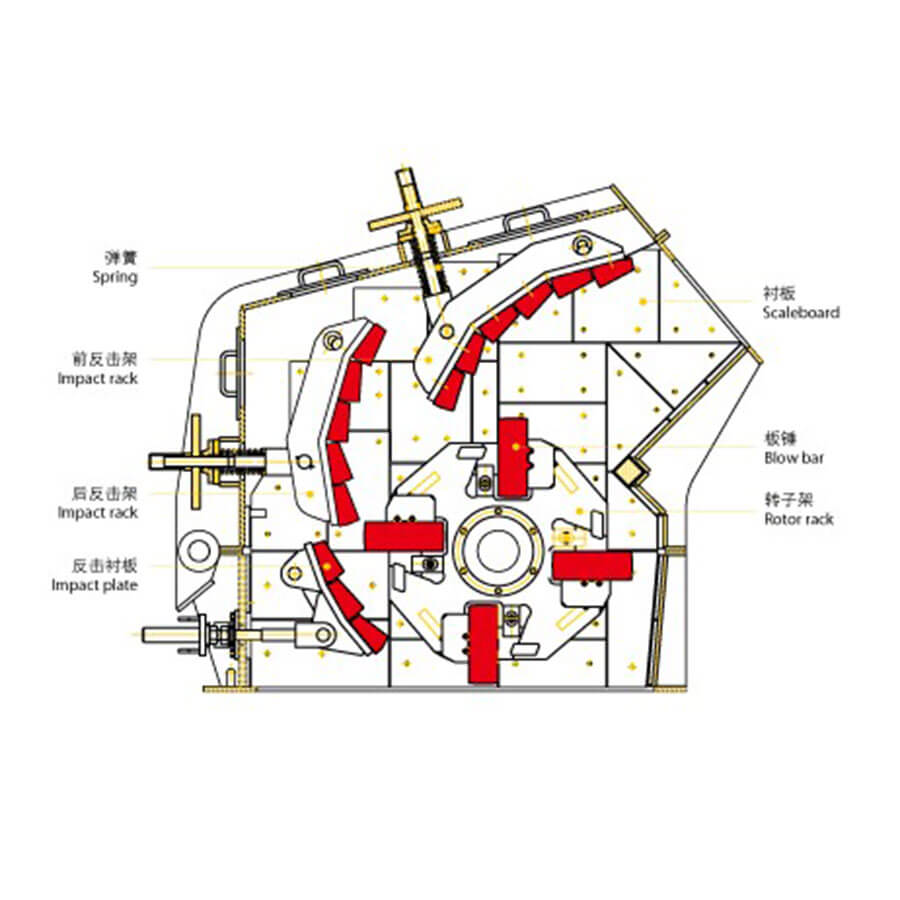

Product Structure

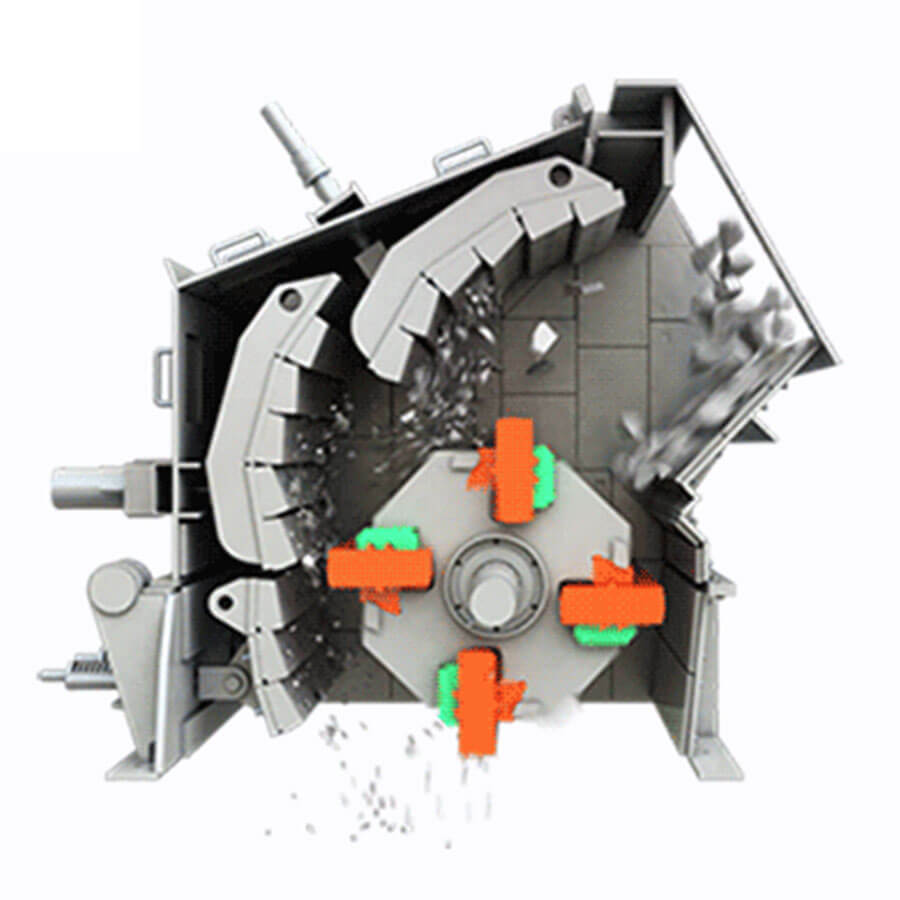

Impact crusher is mainly composed of heavy rotor, wear-resistant hammer, impact liner, hydraulic cover opening device, etc.

How it works

Material enters the crushing chamber and is struck by high-speed rotating blow bars. The particles collide repeatedly between the impact liners and blow bars until reaching the desired size, then discharge through the outlet.

Application Areas

Impact crusher is a kind of crushing equipment commonly used in the fields of ore, building materials, etc., especially suitable for crushing medium hardness or soft materials. It is widely used in many fields such as ore crushing, building materials, environmental protection industry, fertilizer production, etc. It is especially excellent in crushing limestone, granite, coal, construction waste, etc.

Product Advantages

The main advantages of the impact crusher are as follows:

1.Large crushing ratio: It can crush materials efficiently, greatly reducing the particle size of materials and relieving the pressure of subsequent crushing processes.

2.Good finished product shape: Using the impact crushing principle, it can make the materials form more regular cubic particles during the crushing process, with a low content of needle – like and flake – like particles. The product particle size is uniform, which is conducive to improving the quality of the finished product.

3.Strong processing capacity: The reasonable structural design allows large – sized materials to enter the crusher. At the same time, through the optimized design of the crushing chamber and rotor, a high material processing capacity is achieved.

4.Long – lasting wearing parts: High – wear – resistant materials are used to manufacture wearing parts such as impact plates and hammers, which improves the wear resistance and impact resistance of the wearing parts, prolongs their service life, and reduces the maintenance times and downtime of the equipment.

5.Easy operation and maintenance: The equipment has a simple structure, and the installation and disassembly of components are relatively convenient, which is convenient for daily inspection, maintenance, and replacement of wearing parts, reducing the labor intensity of operators and the maintenance cost.

Product Parameters

| Model | Rotor size(mm) | Input mouth size(mm) | Max feeding size(mm) | Capacity(th) | Power(kw) |

| PF-1007 | φ1000×700 | 400×730 | ≤250 | 15-60 | 45 |

| PF-1010 | φ1000×1050 | 400×1080 | ≤300 | 50-90 | 55 |

| PF-1210 | φ1250×1050 | 450×1150 | ≤400 | 70-130 | 90 |

| PF-1214 | φ1250×1400 | 480×1500 | ≤430 | 100-180 | 132 |

| PF-1315 | φ1320×1500 | 860×1520 | ≤500 | 130-220 | 185 |

| 3-PF1210 | φ1250×1050 | 450×1150 | ≤400 | 70-130 | 110 |

| 3-PF1214 | φ1250×1400 | 480×1500 | ≤430 | 100-180 | 132 |

| 3-PF1315 | φ1320×1500 | 860×1520 | ≤500 | 130-220 | 200 |

| 3-PF1320 | φ1320×2000 | 900×2000 | ≤500 | 160-350 | 280 |

| 3-PF1520 | φ1512×2000 | 930×2040 | ≤700 | 300-450 | 450 |

| 3-PF1620 | φ1612×2000 | 1150×2040 | ≤700 | 400-550 | 560 |

| 3-PF1820 | φ1800×2000 | 1620×2040 | ≤700 | 500-800 | 710 |

| RS1315 | 1300×1500 | 1540×930 | ≤600 | 250-350 | 250-315 |

| RS1415 | 1400×1500 | 1540×1320 | ≤700 | 350-550 | 250-315 |

| RS1520 | 1500×2000 | 2040×520 | ≤900 | 400-600 | 400-500 |

| RS1620 | 1600×2000 | 2040×1630 | ≤1100 | 500-900 | 400-500 |

| RS2023 | 2000×2300 | 2400×1920 | ≤1300 | 1200-2000 | 1000-1200 |

Have you decided on the model you want to buy? If you can’t find the model you want, please contact us for consultation.

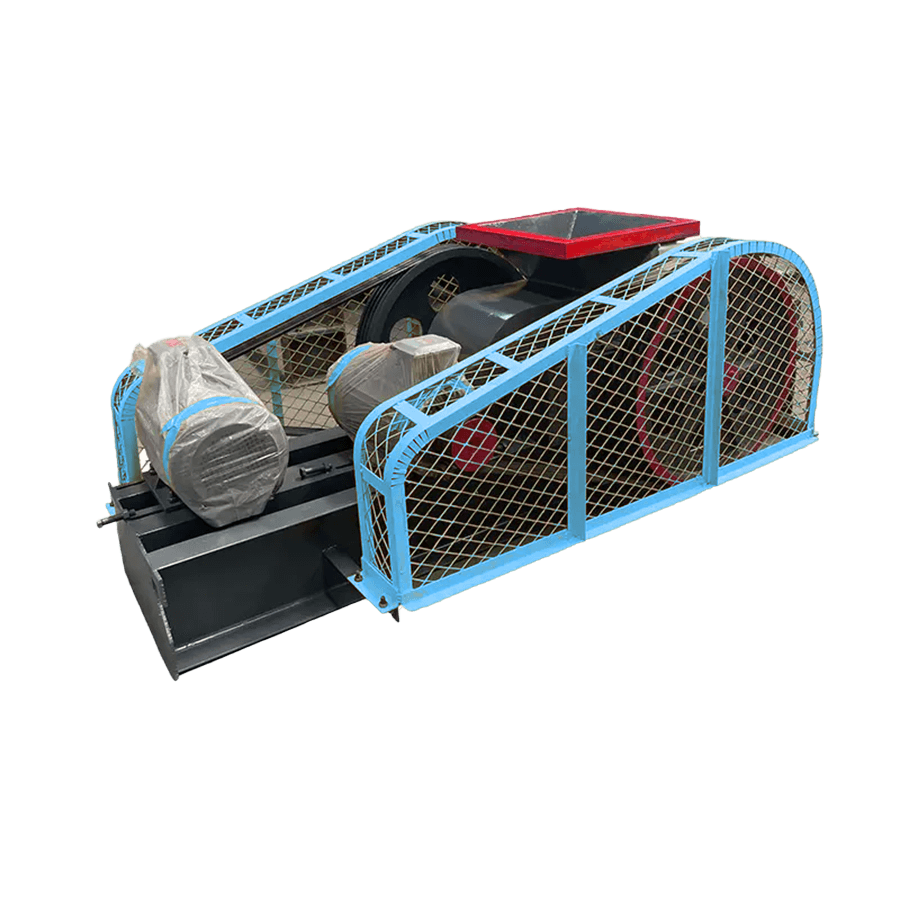

More related cases

The impact crusher produced by Henan Reacore can be used for ore crushing. Whether it is the crushing operation in mining, metallurgy, construction, highway, railway, cement industry, or the secondary crushing of construction waste bricks, the impact crusher of Henan Reacore is your best choice.

Why Choose Us

We have a professional team of engineers who can design and manufacture production solutions according to your needs.

We have a professional modern production workshop, and all the equipment leaving the factory has been quality inspected.

We have many years of manufacturing experience, all equipment is independently developed and produced, the price is more favorable.

We provide a full range of technical support and can provide you with high-quality purchasing services and after-sales services.

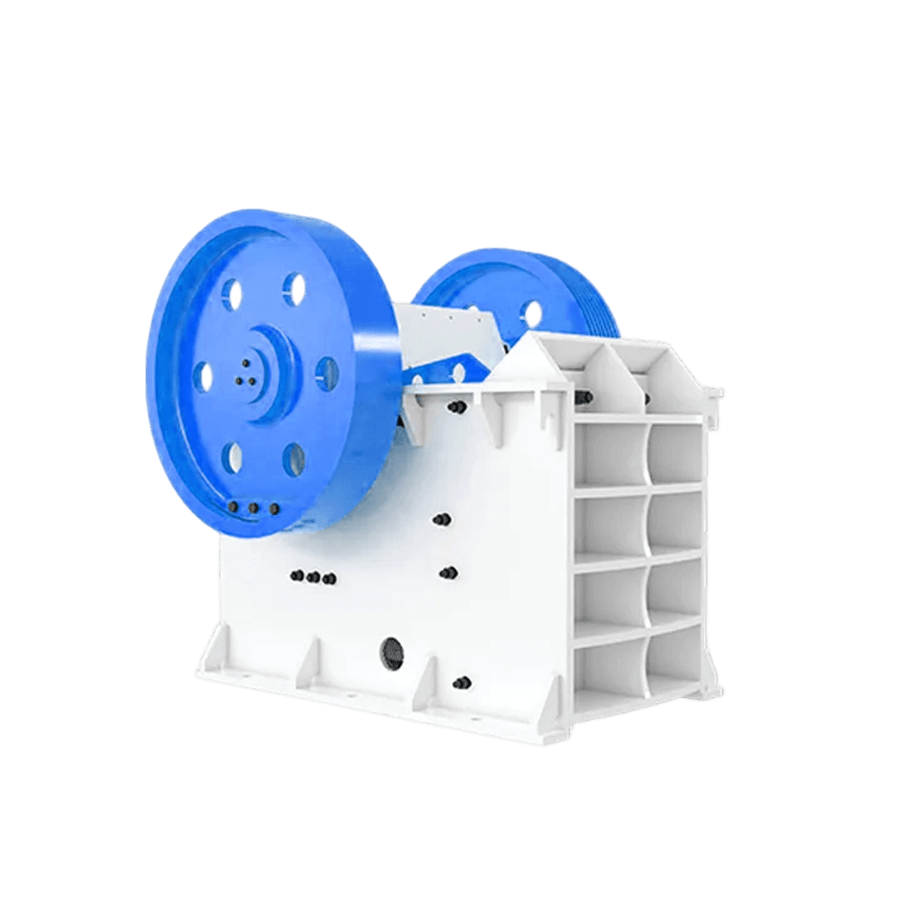

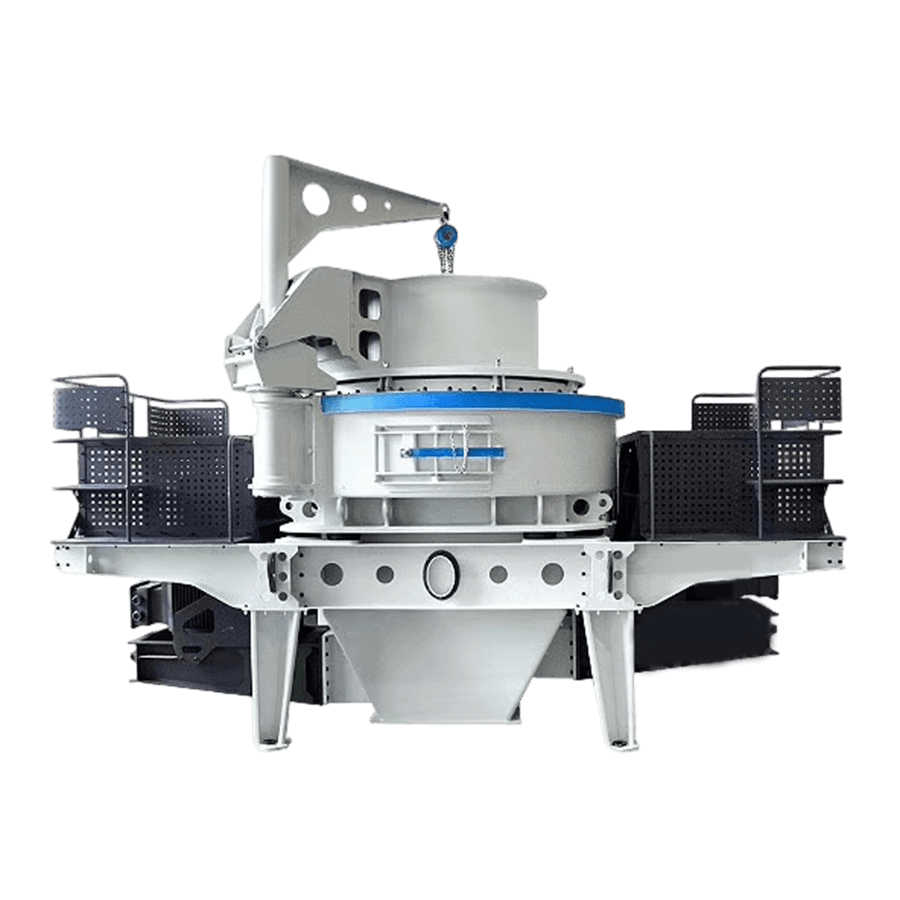

More related products you may want to know

contact us for quote

You can tell us your needs from the following aspects:

1. What is the product name and model you want to know?

2. What type of project do you plan to buy our equipment for?

3. When will you start this project?

4. Where will you carry out your project?

If you don’t know how to choose a specific product, or you need a special project design solution, you can leave your contact information and our technical engineers will design a special solution for you.