Double Roller Crusher For Sale

Applicable materials:

Materials that need to be finely crushed include coal gangue, gypsum, granite, basalt, limestone, marble, quartz, pebbles, bricks, waste brick slag, etc.

Feeding size: 1-100 mm

Power: 5.5*2-220*2 Kw

Capcity: 2-250 T/h

What is a double roller crusher

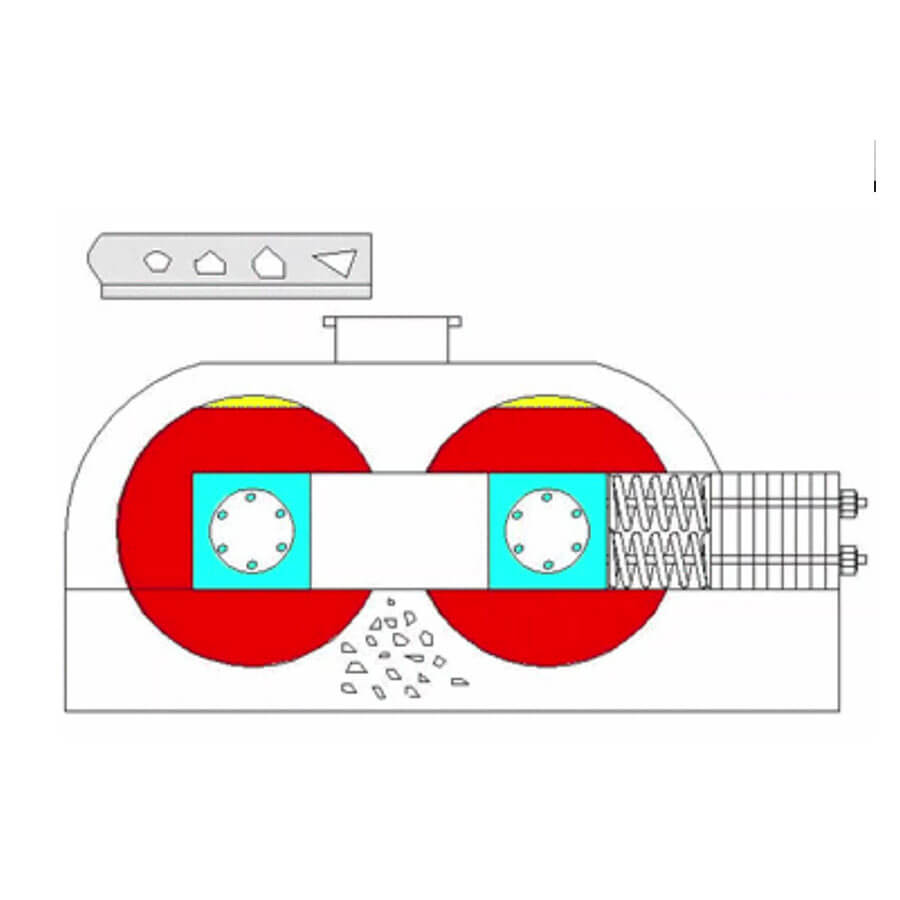

The double-roll crusher is a crushing machine that uses two relatively rotating rollers to crush materials. It is mainly composed of a roller group, roller support bearings, a clamping and speed regulating device, and a drive device. It is suitable for fine crushing operations with a feed size of less than 80 mm and a finished product size of 50 microns to 20 mm.

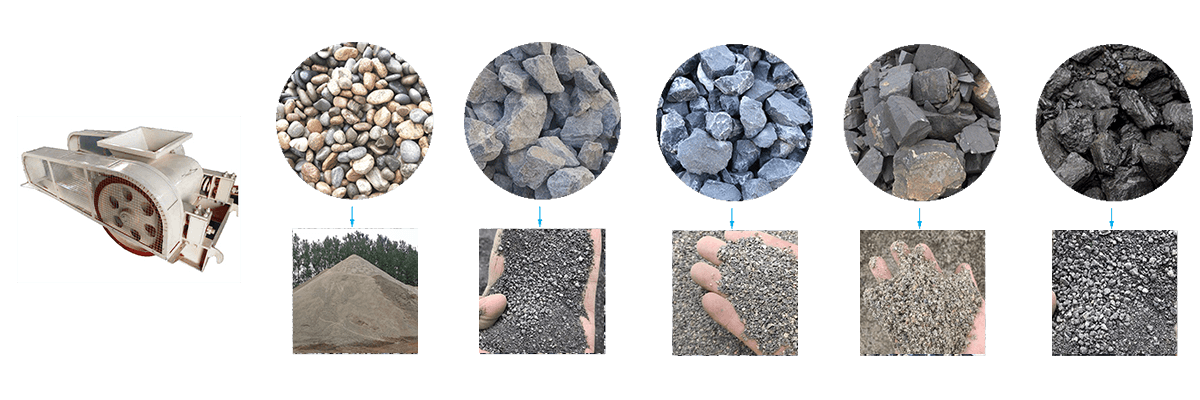

For example, in the mining industry, pebbles and construction waste are crushed to make artificial sand; in the mining industry, iron ore and quartz are finely crushed; in the ceramic industry, raw materials are crushed; in the coal industry, they can be directly crushed after iron and impurities are removed. It is suitable for crushing coarse and brittle block materials, with a large feed size and an adjustable discharge size.

Types of double roller Crusher We Sale

The roll crushers produced by Henan Reacore can be divided into ordinary roll crushers, toothed roll crushers, and smooth roll crushers according to the different roll surfaces; they can be divided into roll crushers and hydraulic roll crushers according to the different capacities.

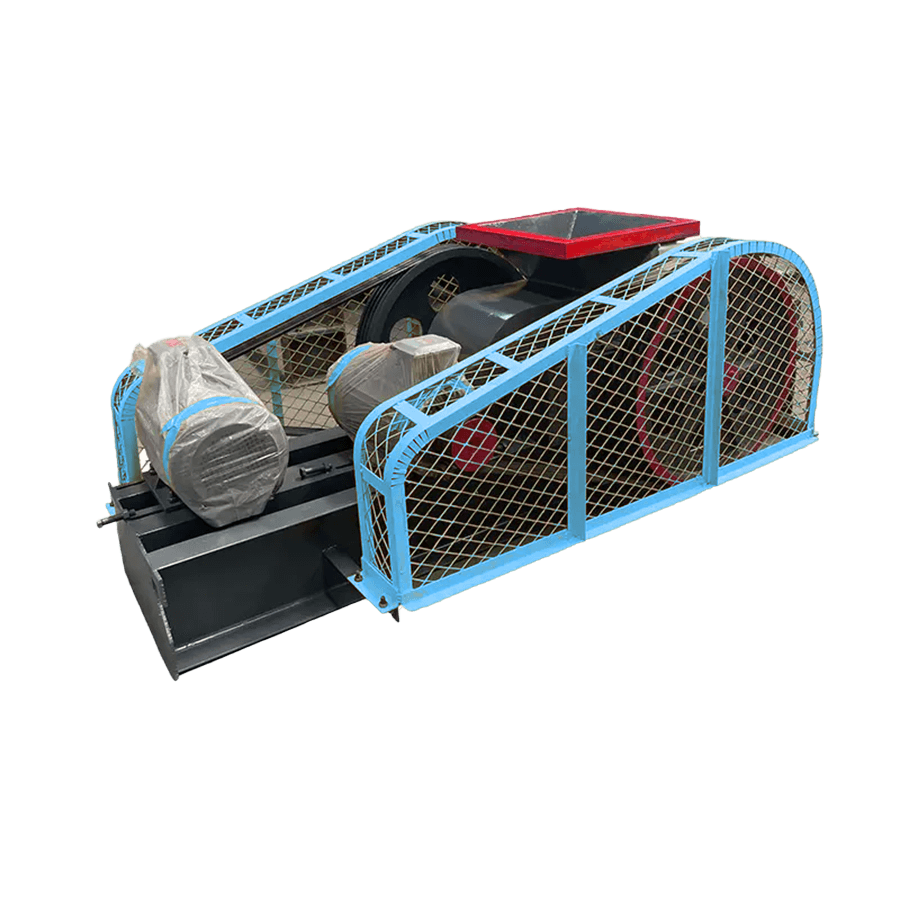

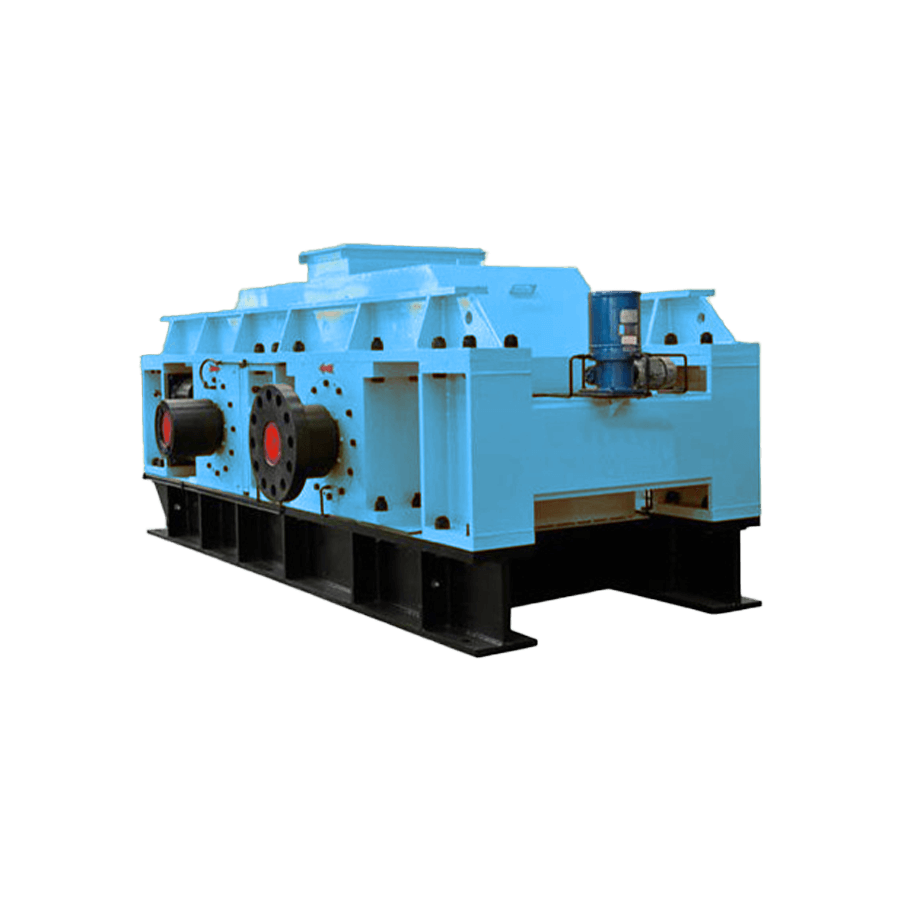

double roller crusher

Roller crusher is a common mechanical equipment used for material crushing, which is widely used in mining, building materials, chemical industry, metallurgy and other industries. Its main function is to crush materials through two rollers moving relative to each other.

double roller crusher

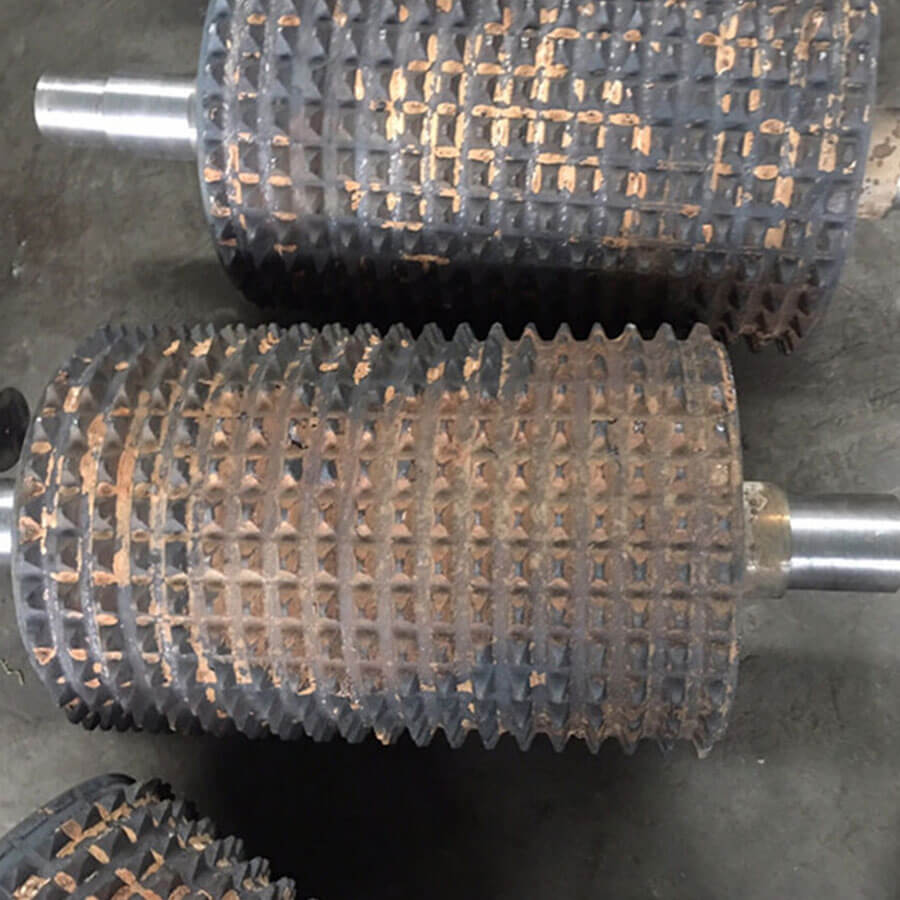

The roller skins of the double-roll crusher produced by Henan Reacore can be selected according to the needs, such as ordinary roller skins, toothed roller skins and smooth roller skins.

Capacity: 2-250 t/h

Feeding size: 1-100 mm

Voltage:220v/380v/415v/440v/480v

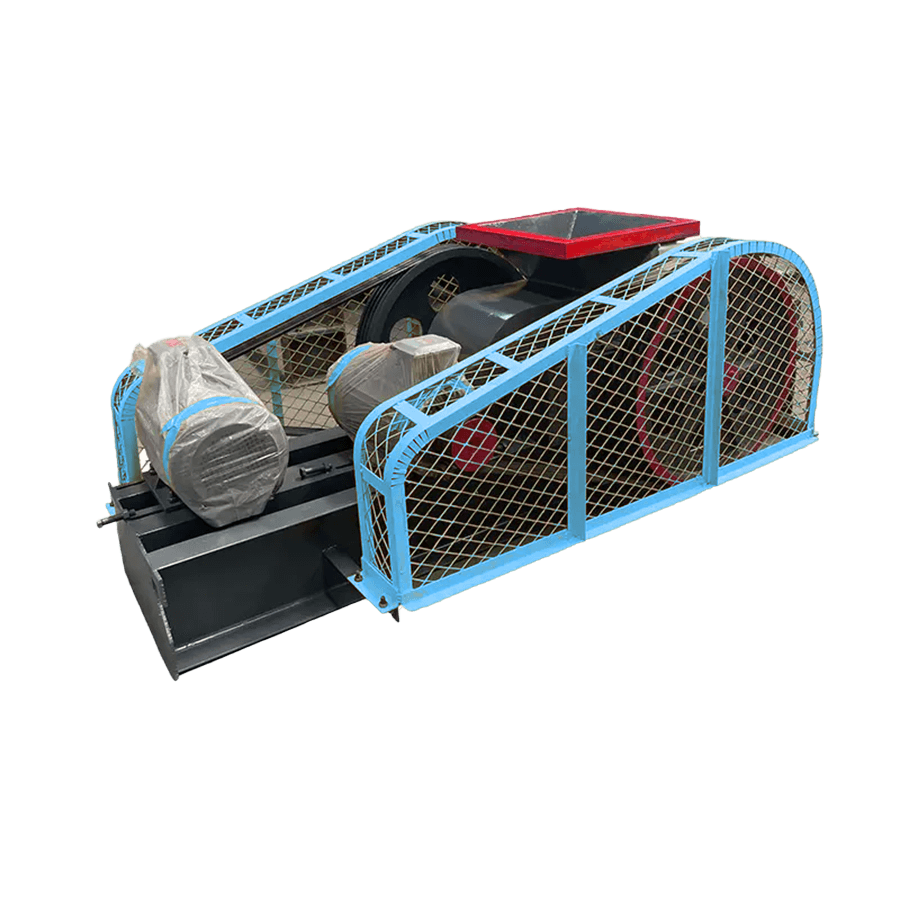

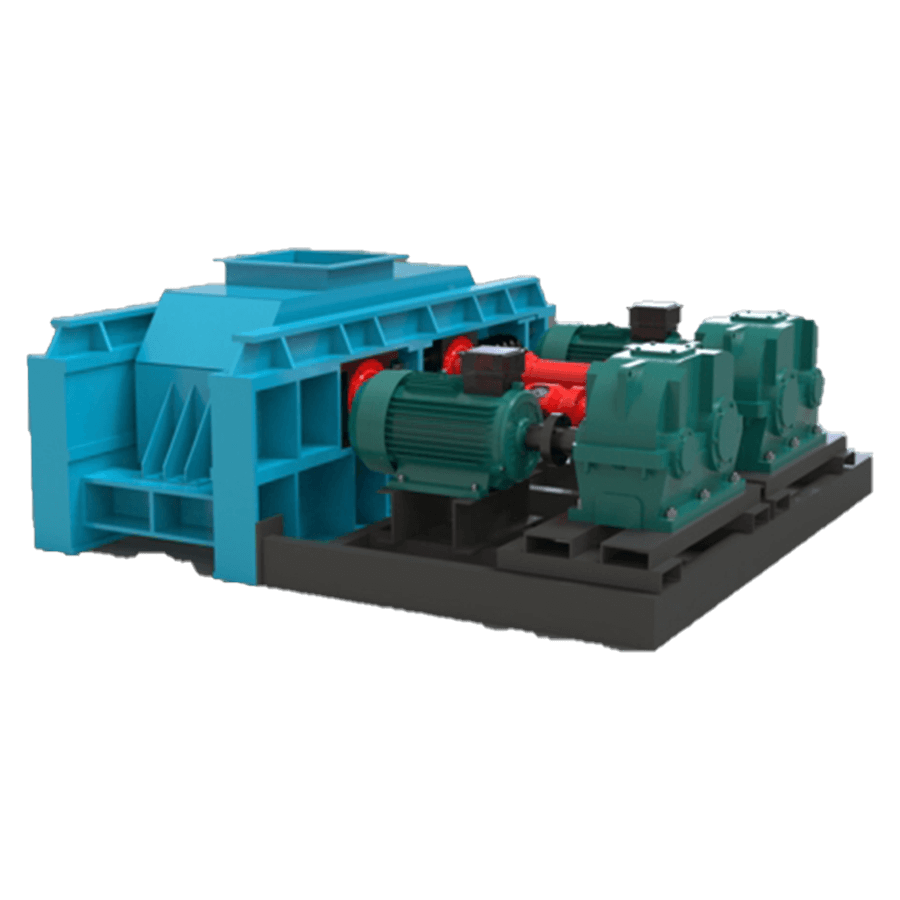

Hydraulic roller crusher

The hydraulic double-roll crusher is an upgraded model of the double-roll crusher. It adds a hydraulic device on the original basis to improve the crushing efficiency and is suitable for large-scale crushing production lines.

Hydraulic roller crusher

The roller of the hydraulic double-roll crusher produced by Henan Reacore is made of wear-resistant alloy, the gap can be adjusted, the service life is long, and the discharge range is controllable.

Capacity: 10-250 t/h

Feeding size: 1-150 mm

Voltage:220v/380v/415v/440v/480v

Product Structure

The double roll crusher mainly consists of the frame, roll wheels, transmission device, and adjustment device. The frame supports the equipment. The roll wheels crush materials by extrusion. The transmission device drives the roll wheels to rotate. The adjustment device can change the distance between the two roll wheels to meet different material and production requirements.

How it works

Motor drives the rotor quickly in the crushing cavity. Raw materials enter the crusher through the feeding inlet and are impacted, cut and ground by high-speed hammer heads. There is a grate under the rotor assemblly, so that materials with size smaller than the grate mesh will be screened out and others are left to be further hammered until they reach the standard size. The size of the final product can be adjusted by changing the grate, the gap between the rotor assemblly and the grate can also be adjusted according to different requirements.

Application Areas

The double roll crusher is an efficient, economical and adaptable crushing equipment, suitable for crushing materials with medium hardness or below in various industries. It has the advantages of easy operation, adjustable crushing size and strong durability, and is an indispensable equipment in the mining, building materials, chemical and other industries.

Product Advantages

1. Simple and compact structure, light body, stable and reliable performance, large crushing ratio.

2. Adjustable discharge port. Users can adjust the crusher according to their finished product needs.

3. The crushing working mode is adopted, and the particle size of the crushed material is relatively uniform.

4. Low operating cost, good durability, and reduced maintenance cost.

5. Low energy consumption and high energy utilization rate.

6. Wide range of applications, able to handle various medium-hard and brittle materials. Suitable for some materials with large particles that are not suitable for other types of crushers.

7. Strong wear resistance, the roller surface is usually made of wear-resistant materials, which can cope with long-term and high-intensity crushing operations.

8. Small footprint, suitable for use in places with limited space.

Product Parameters

| Model | Roller Diameter(mm) | Roller Length(mm) | Feeding Size(mm) | Capacity(th) | Motor Power(kw) |

| 2PG-400X250 | 400 | 250 | ≤ 25 | 2-10 | 2*5.5 |

| 2PG-610X400 | 610 | 400 | ≤ 30 | 5-20 | 2*15 |

| 2PG-610X750 | 610 | 750 | ≤ 30 | 5-30 | 2*18.5 |

| 2PG-750X500 | 750 | 500 | ≤ 35 | 10-40 | 2*18.5 |

| 2PG-800X600 | 800 | 600 | ≤ 40 | 12-50 | 2*22 |

| 2PG-800X800 | 800 | 800 | ≤ 40 | 20-60 | 2*37 |

| 2PG-900X900 | 900 | 900 | ≤ 50 | 30-70 | 2*37 |

| 2PG-1000X1000 | 1000 | 1000 | ≤50 | 50-100 | 2*45 |

| 2PGY-1200×1000 | 1200 | 1000 | ≤50 | 60-120 | 2*75 |

| 2PGY-1200×1200 | 1200 | 1200 | ≤60 | 80-150 | 2*90 |

| 2PGY-1500×1000 | 1500 | 1000 | ≤80 | 90-200 | 2*132 |

| 2PGY-1800×1000 | 1800 | 1000 | ≤ 100 | 130-250 | 2*220 |

Have you decided on the model you want to buy? If you can’t find the model you want, please contact us for consultation.

More related cases

The roll crushers produced by Henan Reacore are widely used in brittle materials with medium hardness or below, such as limestone, coal, ceramics, ore, etc. No matter what raw materials you want to crush, Henan Reacore’s roll crushers are your best choice.

Why Choose Us

We have a professional team of engineers who can design and manufacture production solutions according to your needs.

We have a professional modern production workshop, and all the equipment leaving the factory has been quality inspected.

We have many years of manufacturing experience, all equipment is independently developed and produced, the price is more favorable.

We provide a full range of technical support and can provide you with high-quality purchasing services and after-sales services.

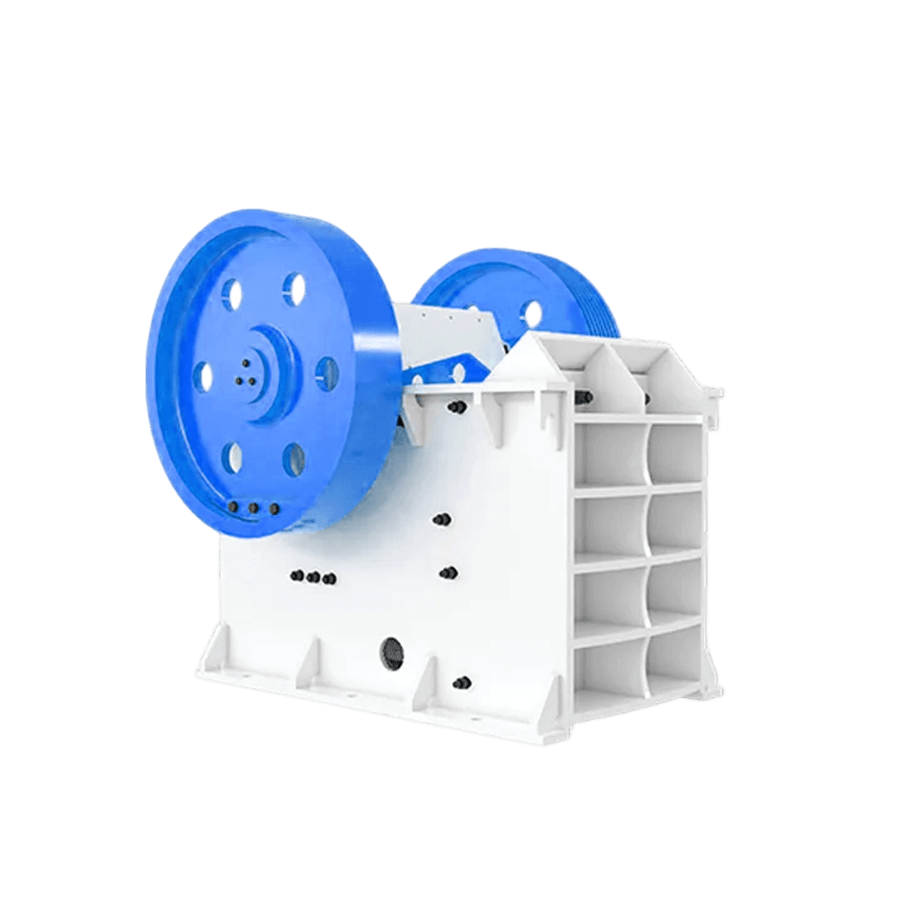

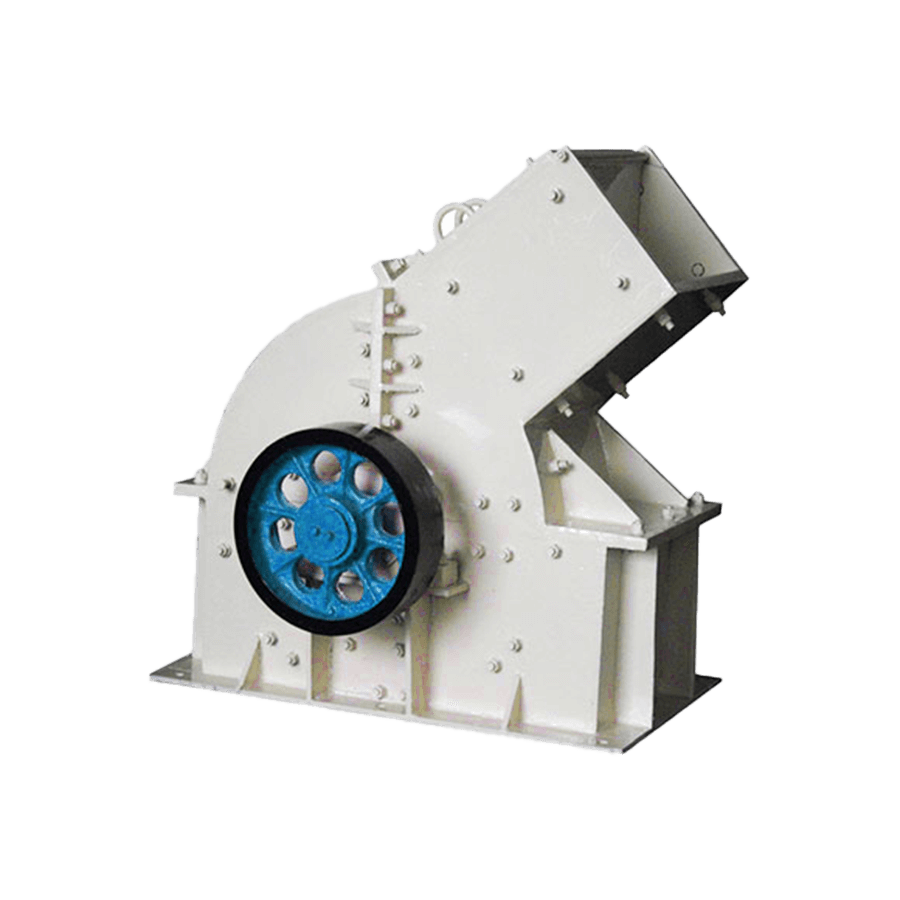

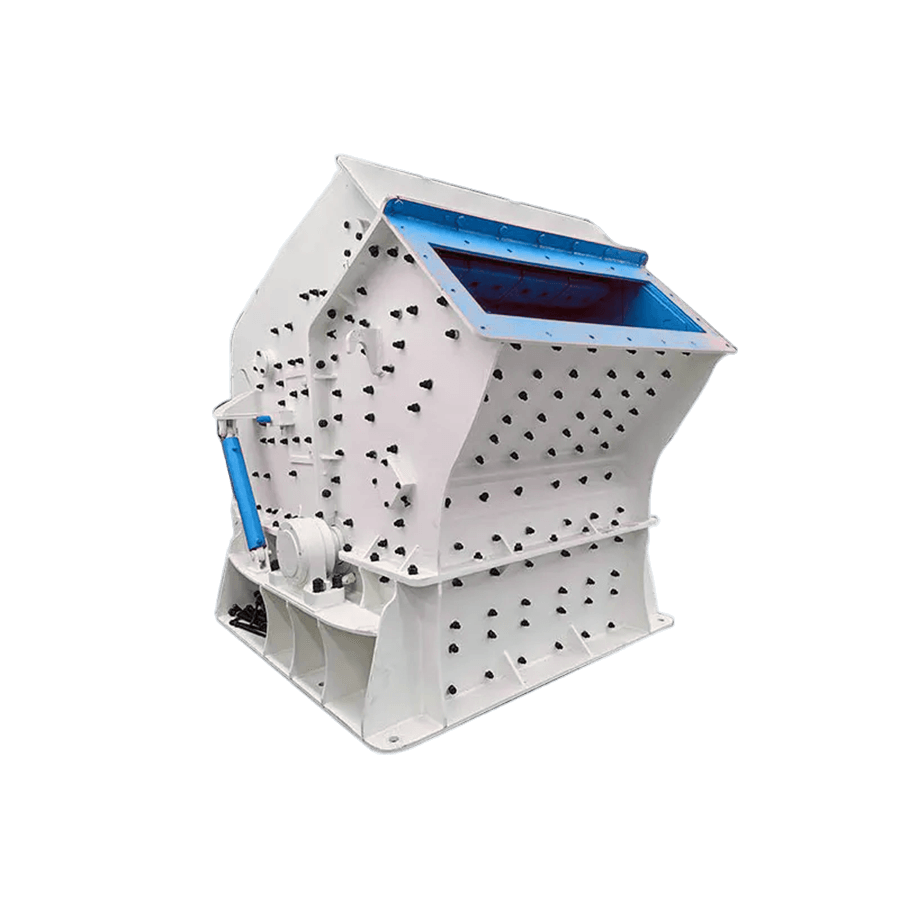

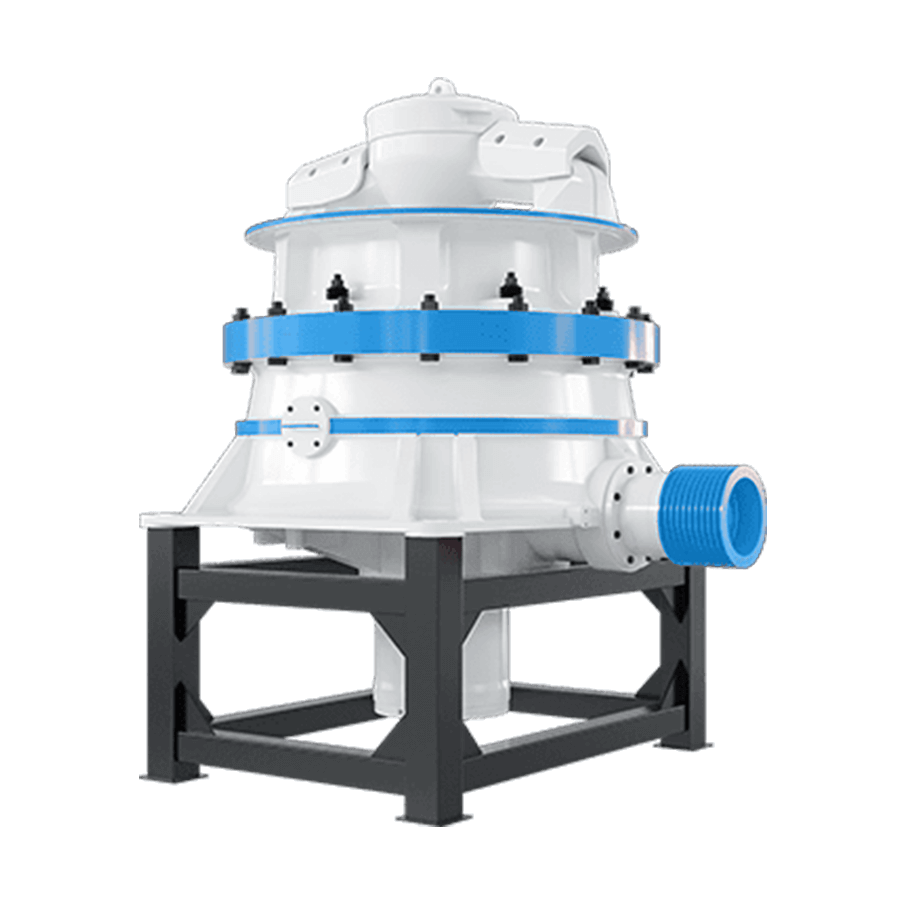

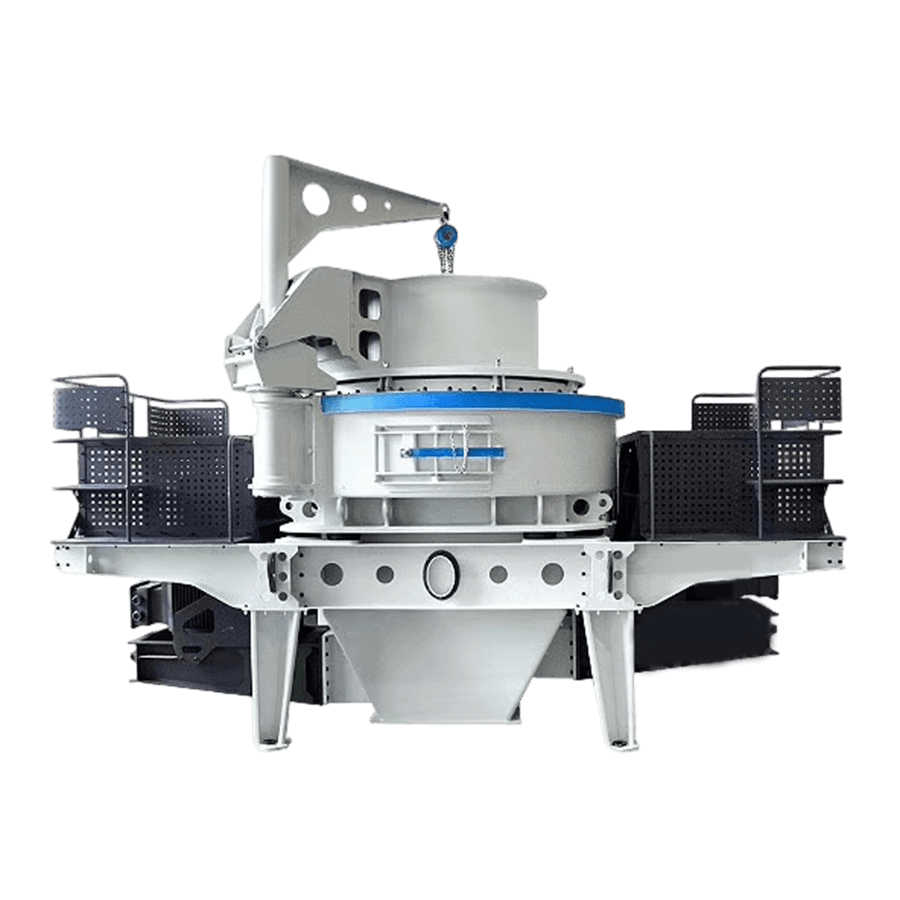

More related products you may want to know

contact us for quote

You can tell us your needs from the following aspects:

1. What is the product name and model you want to know?

2. What type of project do you plan to buy our equipment for?

3. When will you start this project?

4. Where will you carry out your project?

If you don’t know how to choose a specific product, or you need a special project design solution, you can leave your contact information and our technical engineers will design a special solution for you.