VSI Crusher For Sale

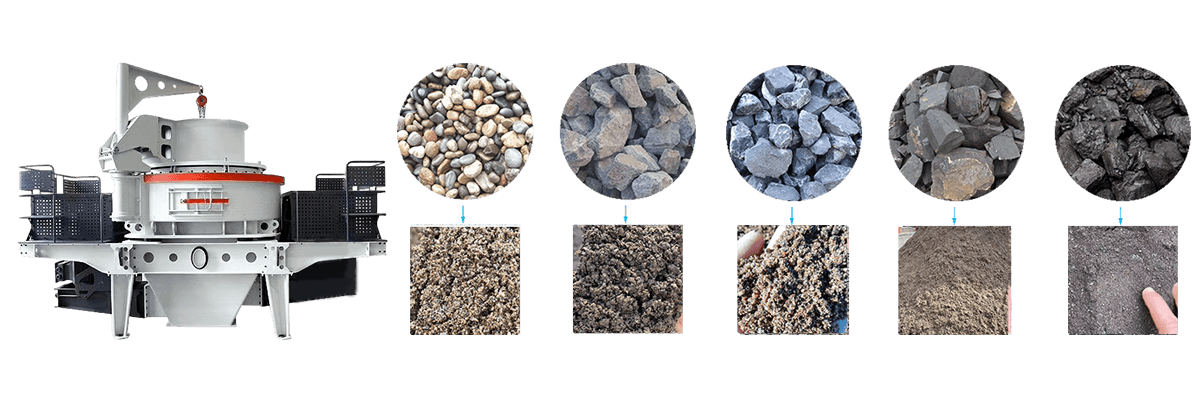

Applicable materials:

Pebbles, limestone, basalt, granite, gangue, clay and other natural ores, rocks and construction waste.

Feeding size: 30-50 mm

Power: 55*2-220*2 Kw

Capcity: 60-600 T/h

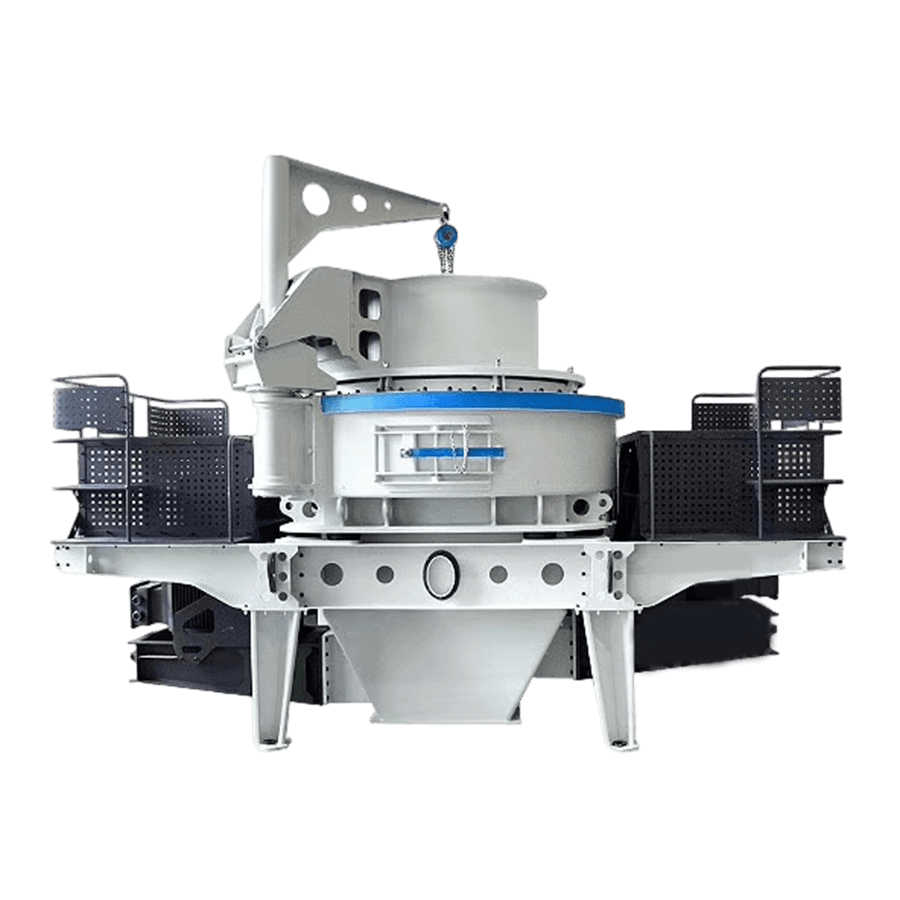

What is a VSI crusher

Vertical shaft impact crusher is also called VSI sand making machine. It is mainly used to produce construction sand. VSI machine is the most advanced equipment for artificial sand production at present. It is designed to provide high-quality sand and stone aggregate for highway, high-speed railway, building, hydropower dam construction, concrete mixing plant.

It is also used in the field of artificial sand making and stone shaping. Usually, VSI sand making plant can be equipped with sand washing machine, stone crusher, vibrating screen to produce artificial sand more economically and efficiently.

Types of VSI Crusher We Sale

The VSI crusher manufactured by Henan Reacore is also called an impact sand making machine. It mainly uses the working principle of stone hitting stone or stone hitting iron, and can crush various ores into artificial machine-made sand.

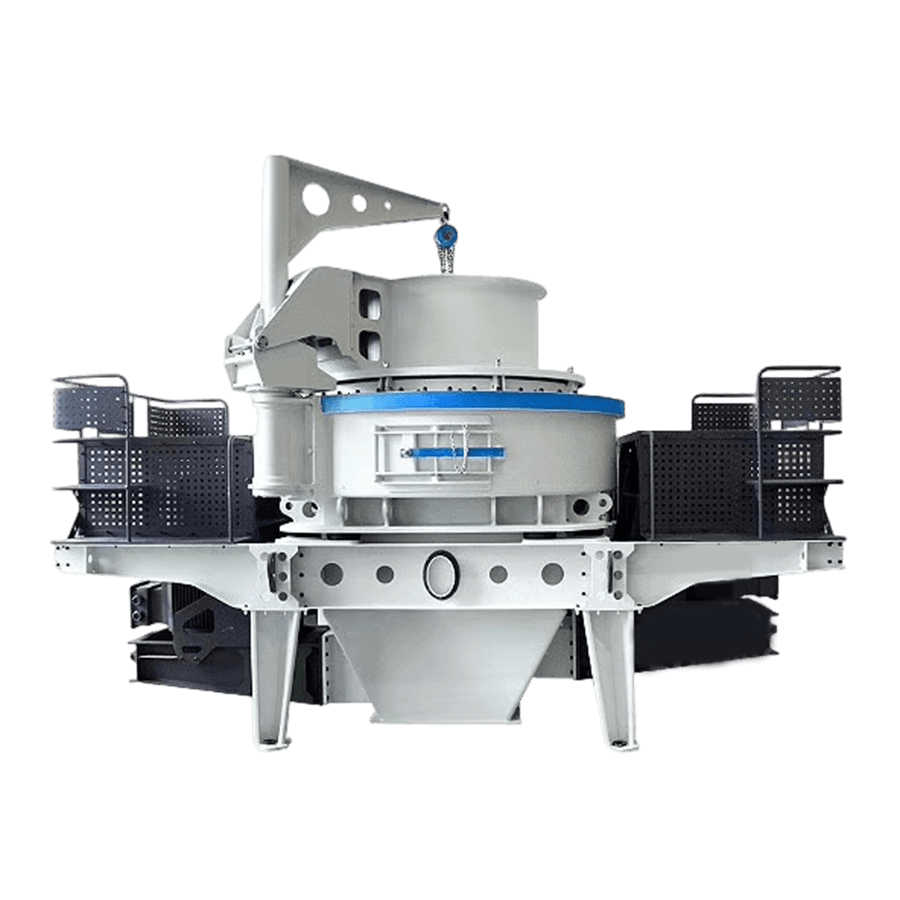

VSI crusher

The VSI crusher manufactured by Henan Reacore has large processing capacity and high output. The cost of vulnerable parts is low; the impact angle of the crushing chamber is reasonably designed. It adopts thin oil lubrication and automatic maintenance.

Vertical Shaft Sand Making Machine

The VSI crusher produced by Henan Reacore adopts a new design, which optimizes the working process and produces better particle shape.

Capacity: 60-600 t/h

Feeding size: 30-50 mm

Voltage:220v/380v/415v/440v/480v

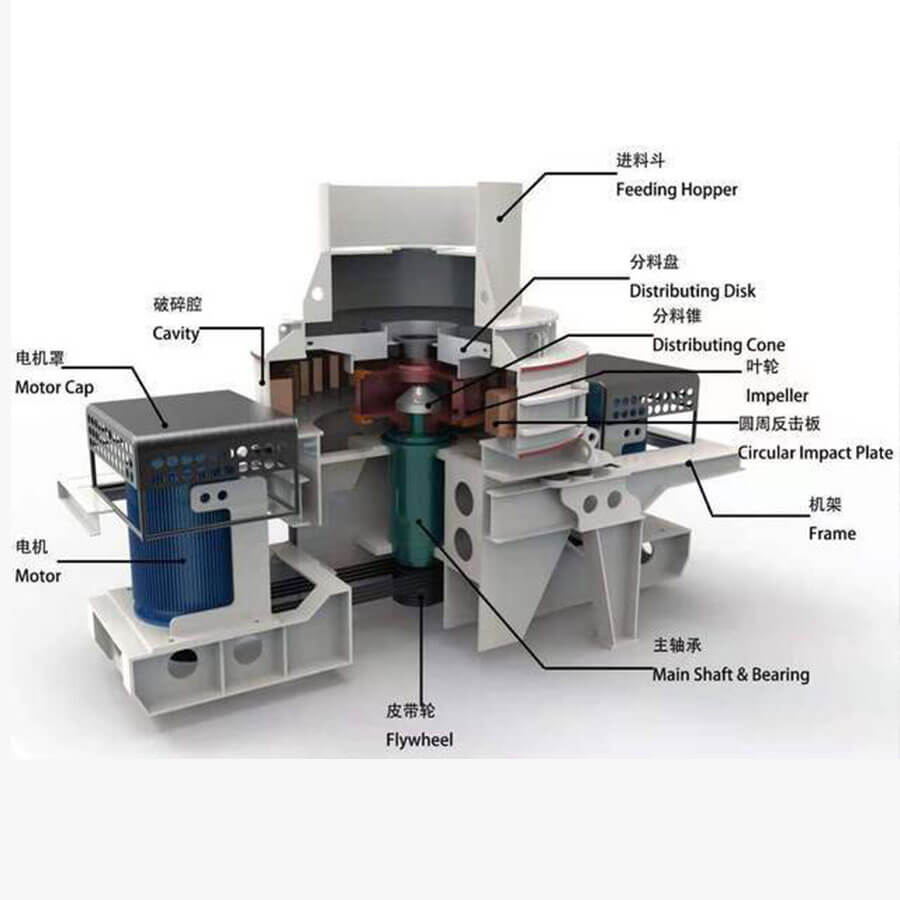

Product Structure

The VSI sand making machine mainly consists of the feed hopper, distributor cone, impeller, crushing chamber, vortex chamber, and base. Materials enter through the feed hopper, and under the action of components such as the distributor cone, they are accelerated and crushed by the impeller in the crushing chamber and vortex chamber. The base plays a supporting and stabilizing role.

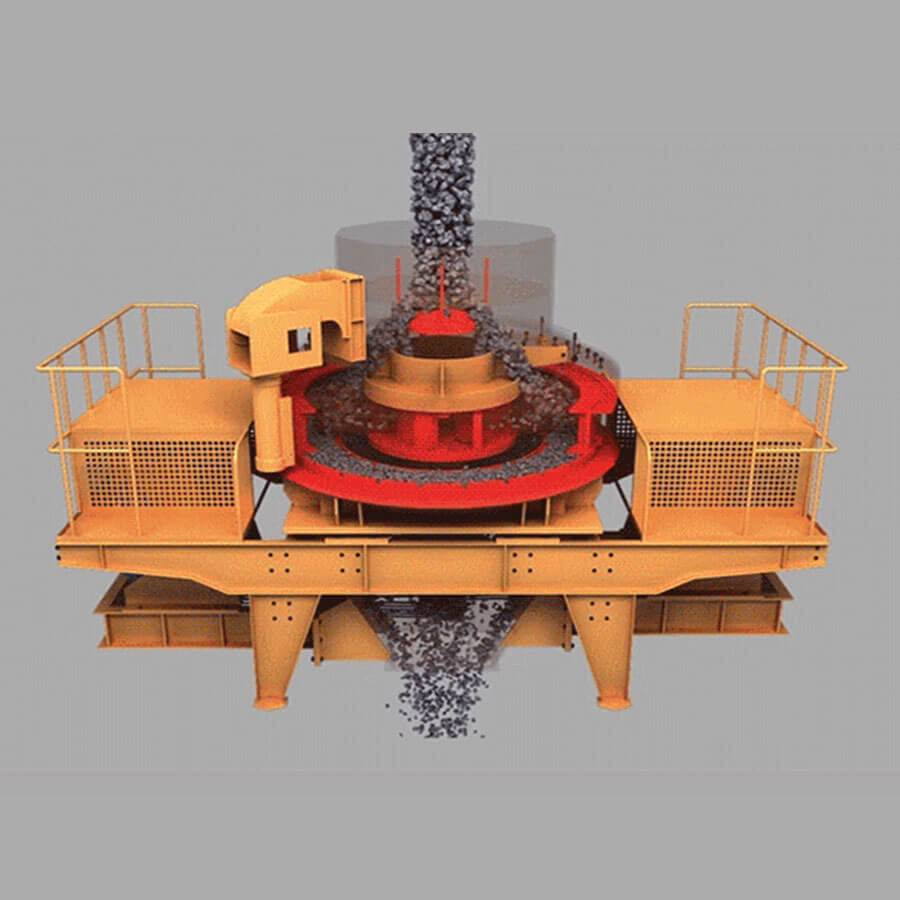

How it works

Hard stone materials fall into the crusher and are divided into two parts. One part goes into the high-speed-running impeller of the machine, and the other part goes around the impeller.The two parts materials bump and crush fast during the effect of centrifugal force. Then the materials run like swirl, bump and rub to each other again and again. The finished products go out from the bottom of the machine, and users can get the requested products size after screening by vibrating screen. Baichy VSI sand maker adopts central feeding and central cascade feeding way, which can be changed based on customers’ needs.

Application Areas

Vertical shaft impact crusher is mainly used to produce construction sand. It is designed to provide high-quality sand and gravel aggregates for highways, high-speed railways, construction, hydropower dam construction, concrete mixing stations, etc. VSI sand making machine can also be used for artificial sand making and stone shaping.

Product Advantages

1. Excellent finished product particle shape: VSI sand making machine can produce sand and gravel with uniform particle shape, which is particularly suitable for high-demand construction, concrete and other fields, and can provide high-quality sand and gravel products.

2. High efficiency and energy saving: Compared with traditional sand making machines, VSI impact sand making machine can increase the output of sand and gravel when working, while saving energy and having lower energy consumption.

3. Strong adaptability: The equipment can handle a variety of ores of different hardness and types, and is widely used in artificial sand production lines, mine sand making and other fields.

4. Simple operation: VSI impact sand making machine is relatively simple to operate, and maintenance and maintenance are also relatively convenient, saving production and operation costs.

5. Large crushing ratio: VSI sand making machine can achieve a large crushing ratio, can also quickly crush harder materials, and has strong processing capacity.

6. High stability: The use of high-quality wear-resistant materials and advanced technology greatly extends the service life of the machine, long maintenance intervals, and reduces downtime.

Product Parameters

| Model | VSI-7611 | VSI-8518 | VSI-9526 | VSI-1140 | VSI-1145 | |

| Capacity (t/h) | Waterfall and Center Feeding | 120-180 | 200-260 | 300-360 | 450-520 | 500-600 |

| Center Feeding | 60-90 | 100-130 | 150-190 | 225-260 | 250-360 | |

| Feeding Size (mm) | Soft Material | < 35 | < 40 | < 45 | < 50 | < 50 |

| Hard Material | < 30 | < 35 | < 40 | < 45 | < 45 | |

| Rotation Speed (r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | 1180-1280 | |

| Power of the Double Motors (kw) | 2×55 | 2×90 | 2×132 | 2×200 | 2×220 | |

| Overall dimension L*W*H (mm) | 4100×2290×2350 | 4600×2280×2650 | 4600×2350×2850 | 5200×2600×3220 | 5500×2790×3320 | |

| Power Source | 380v:50hz | |||||

| Vibrating Sensor | Inspection Scope:0.1-20mm/s, it can be adjusted continuously | |||||

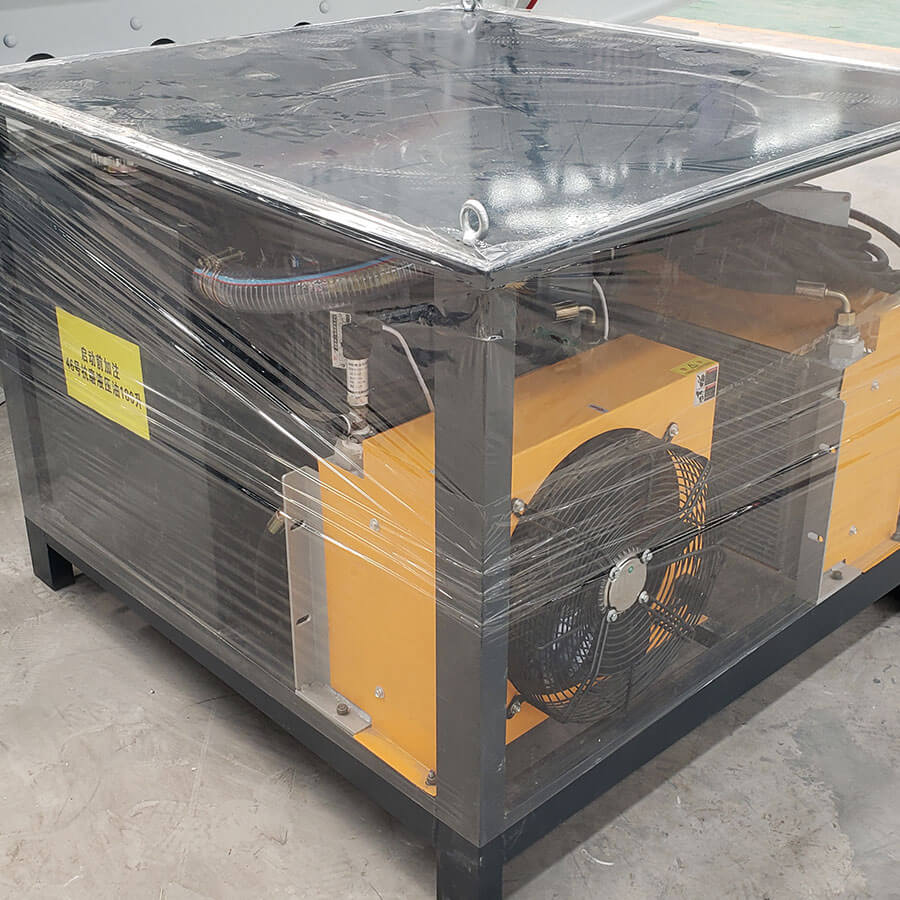

| Hydraulic Lubrication Station | Power of Double Oil Pump | 2×0.31kw | ||||

| Safety | Double oil pumps make sure supply of oil with; Stop automatically without oil flow or oil pressure; Water cooled; Heating start the motor in winter | |||||

| Overall Dimension L*W*H (mm) | 820x520x1270 | |||||

| Power of Oil-Box Heater | 2kw | |||||

Have you decided on the model you want to buy? If you can’t find the model you want, please contact us for consultation.

More related cases

The VSI crusher produced by Henan Reacore is mainly used to make artificial sand. Whether it is fine crushing of various ores or fine crushing of construction waste, the VSI crusher of Henan Reacore is your best choice.

Why Choose Us

We have a professional team of engineers who can design and manufacture production solutions according to your needs.

We have a professional modern production workshop, and all the equipment leaving the factory has been quality inspected.

We have many years of manufacturing experience, all equipment is independently developed and produced, the price is more favorable.

We provide a full range of technical support and can provide you with high-quality purchasing services and after-sales services.

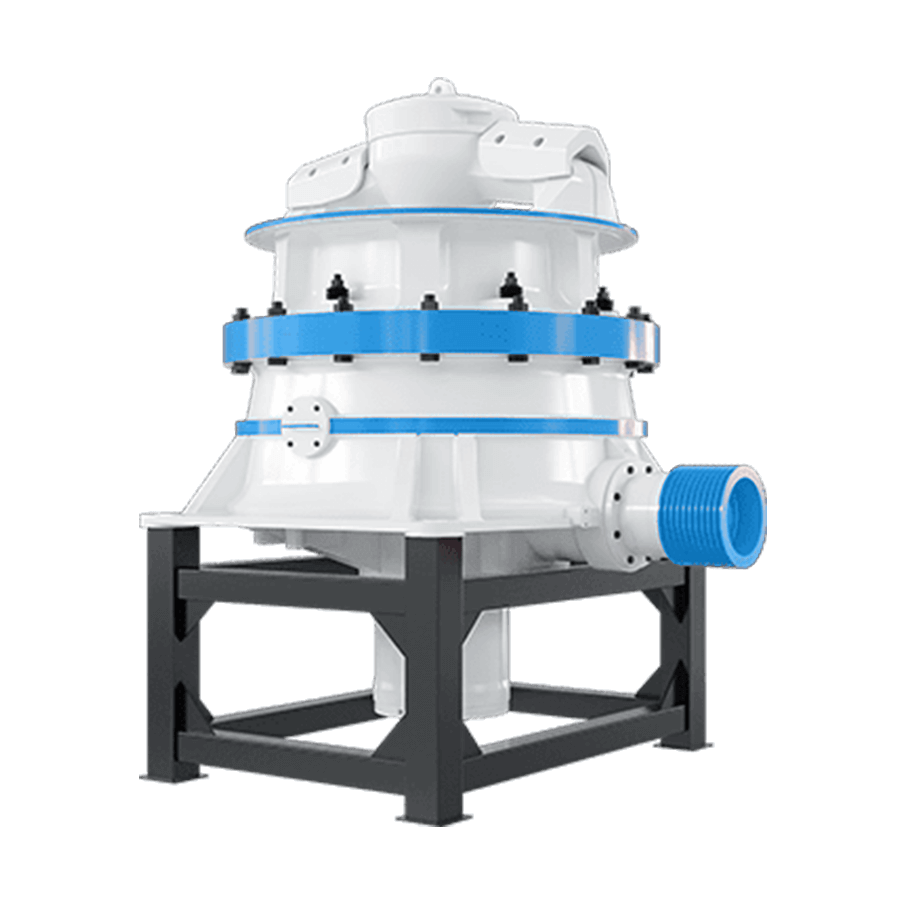

More related products you may want to know

contact us for quote

You can tell us your needs from the following aspects:

1. What is the product name and model you want to know?

2. What type of project do you plan to buy our equipment for?

3. When will you start this project?

4. Where will you carry out your project?

If you don’t know how to choose a specific product, or you need a special project design solution, you can leave your contact information and our technical engineers will design a special solution for you.