Mobile Crushing Plant For Sale

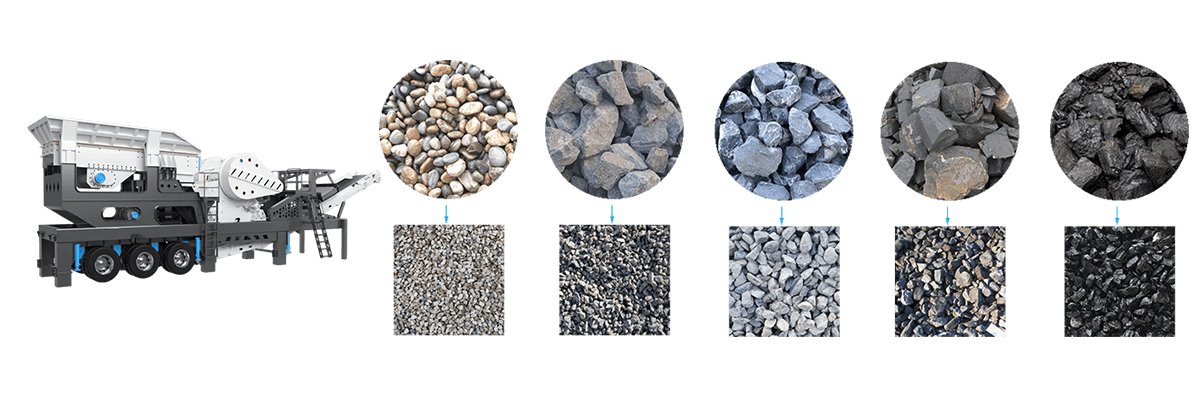

Applicable materials:

Various ores, aggregates, coal ore, construction waste bricks, concrete, etc.

Feeding size: 0-800 mm (Customizable)

Power: 100-500 kw

Capcity: 30-1000 t/h (Customizable)

What is a Mobile crushing Plant

Mobile crushing plant is a new type of crushing equipment that integrates crushing, screening, conveying and other functions. It can be flexibly configured according to the type, output and processing requirements of the material, and can achieve rapid movement and on-site operation.

Mobile crushing station is widely used in mining, construction, metallurgy, highway, railway, cement, garbage disposal and other fields, suitable for processing various types of ores and construction waste and other materials.

Types of mobile Crushing plant We Sale

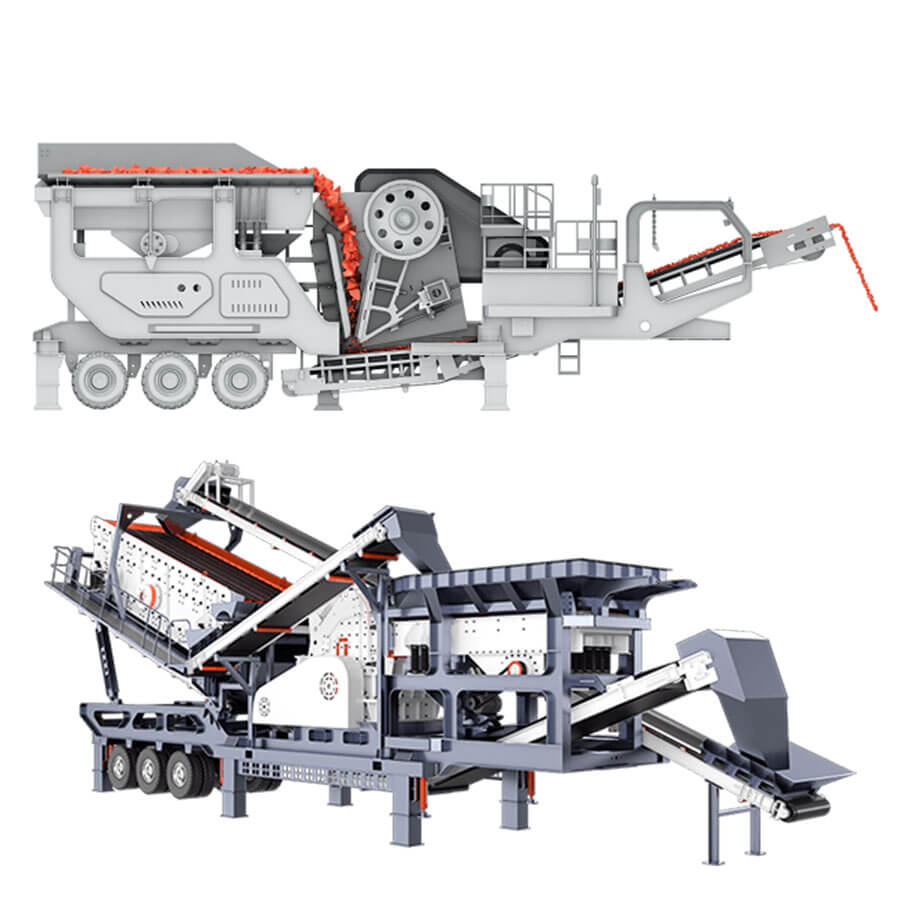

The mobile crushing stations produced by Henan Reacore can be divided into wheeled mobile crushing stations and crawler mobile crushing stations according to the different walking methods.

The wheel type mobile crushing station adopts an integrated design and is equipped with support legs, which is easy to install. It can be transported on the road and transferred to different work sites.

The crawler mobile crushing station uses crawler tracks, is equipped with multi-functional accessories, and is driven by oil and electricity. It is particularly suitable for work sites with complex and narrow terrain.

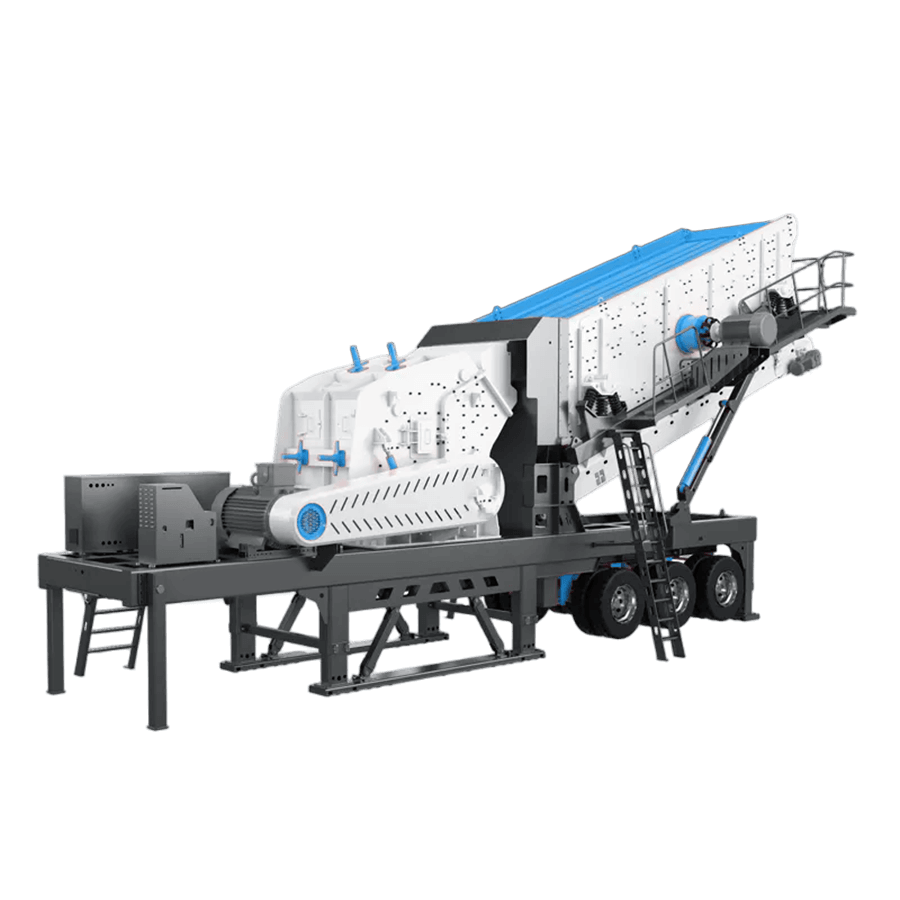

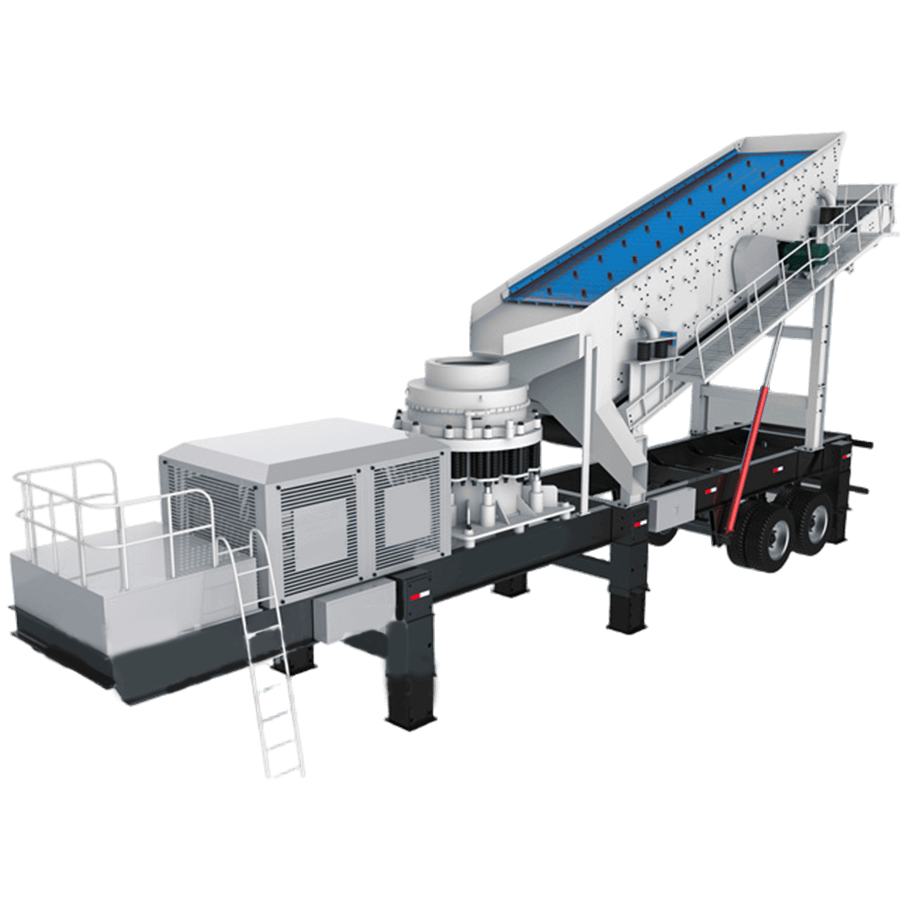

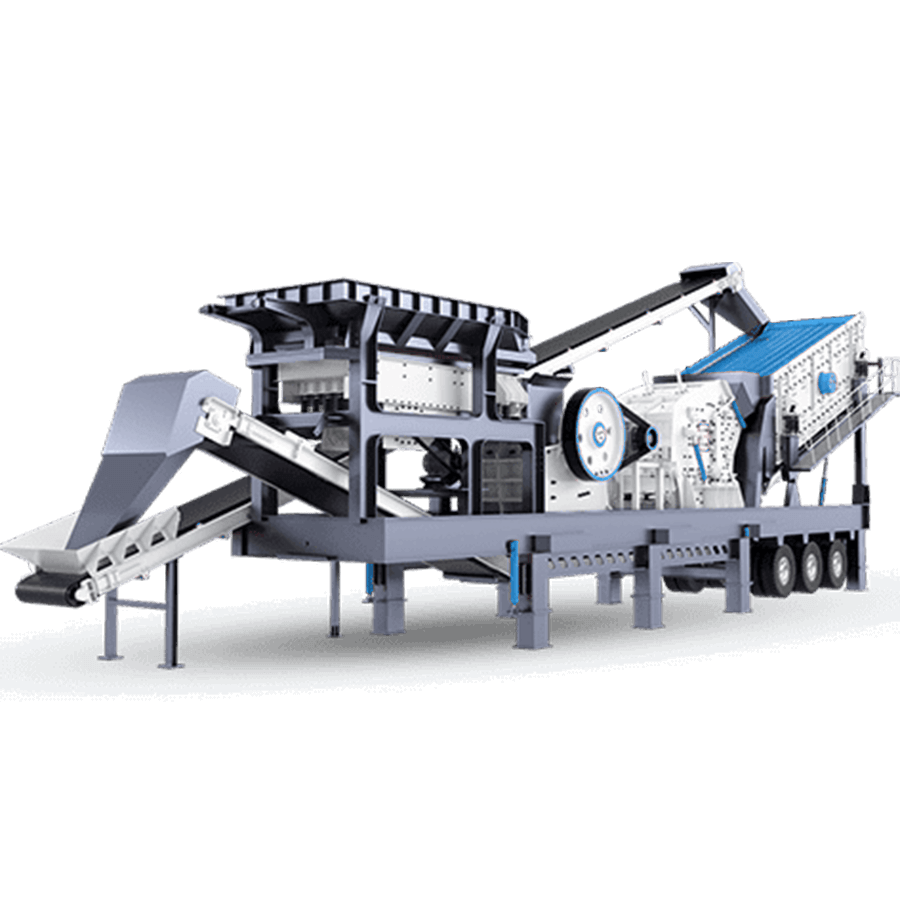

Wheel-type Mobile Crusher

The wheel-type crushing mobile station is a mobile crushing equipment that integrates crushing, screening and conveying. It uses a tire chassis as a carrier, has strong mobility, can be quickly transferred, and can be put into use without complex infrastructure.

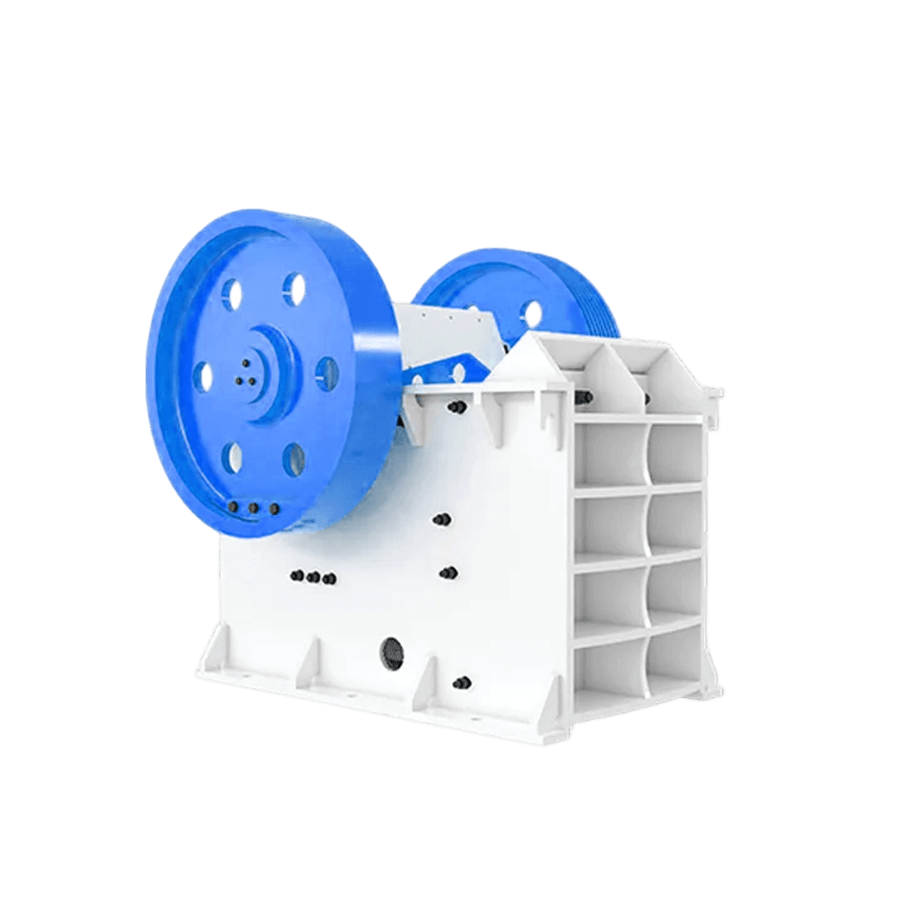

The whole machine can be equipped with jaw crushers, impact crushers, cone crushers and other crushing equipment, and can perform multi-stage crushing of materials such as ore and construction waste.

The screening system can accurately screen out finished products of different specifications, and the conveying system realizes efficient material transmission.

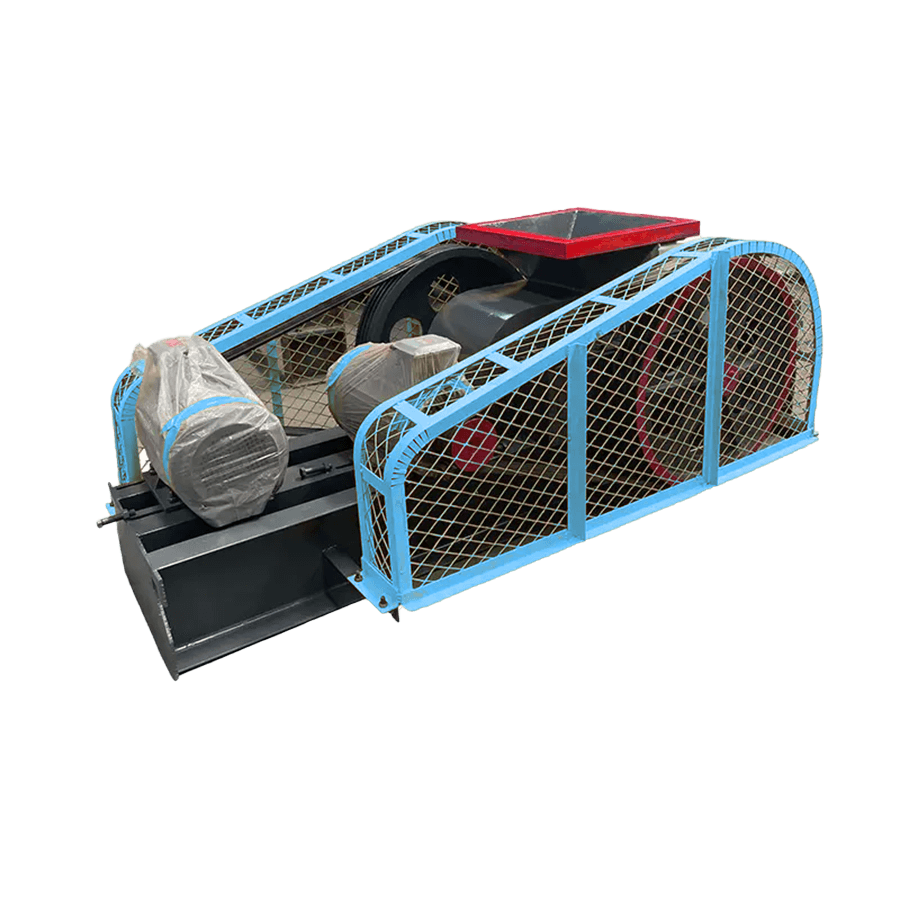

mobile jaw crushing plant

The mobile jaw crushing plant consists of a vibrating feeder, a jaw crusher, a belt conveyor, a vibrating screen, etc. It is widely used in crushing materials with high abrasiveness and extra-large particle size.

Capacity: 30-800 t/h

Feeding size: 1-800 mm

Voltage:220v/380v/415v/440v/480v

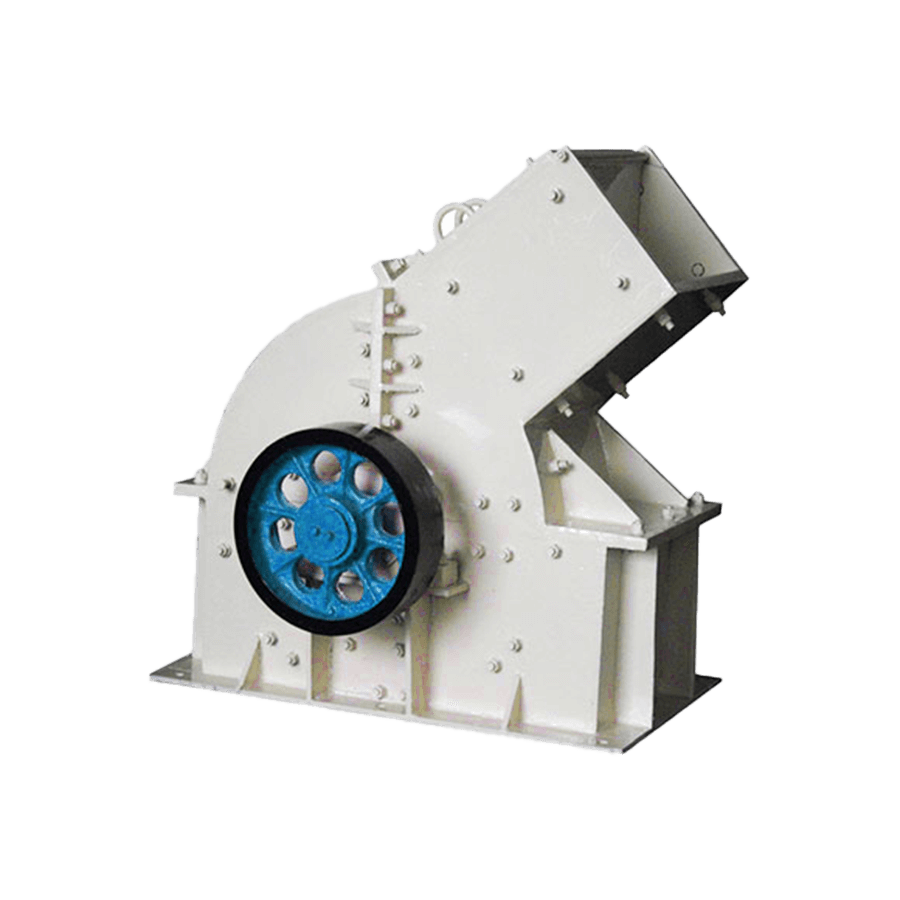

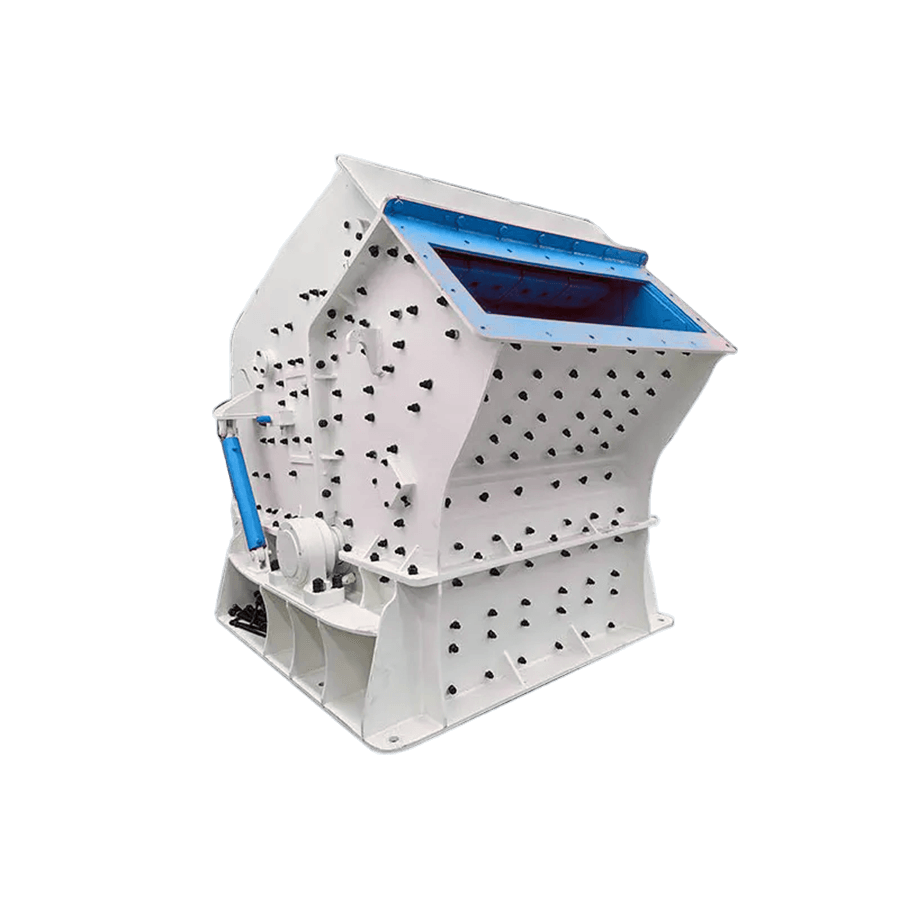

mobile impact crushing plant

The mobile impact crushing plant is mainly used for secondary or tertiary crushing processes, with strong processing capacity, and is suitable for various work sites that need to move materials.

Capacity: 30-600 t/h

Feeding size: 1-500 mm

Voltage:220v/380v/415v/440v/480v

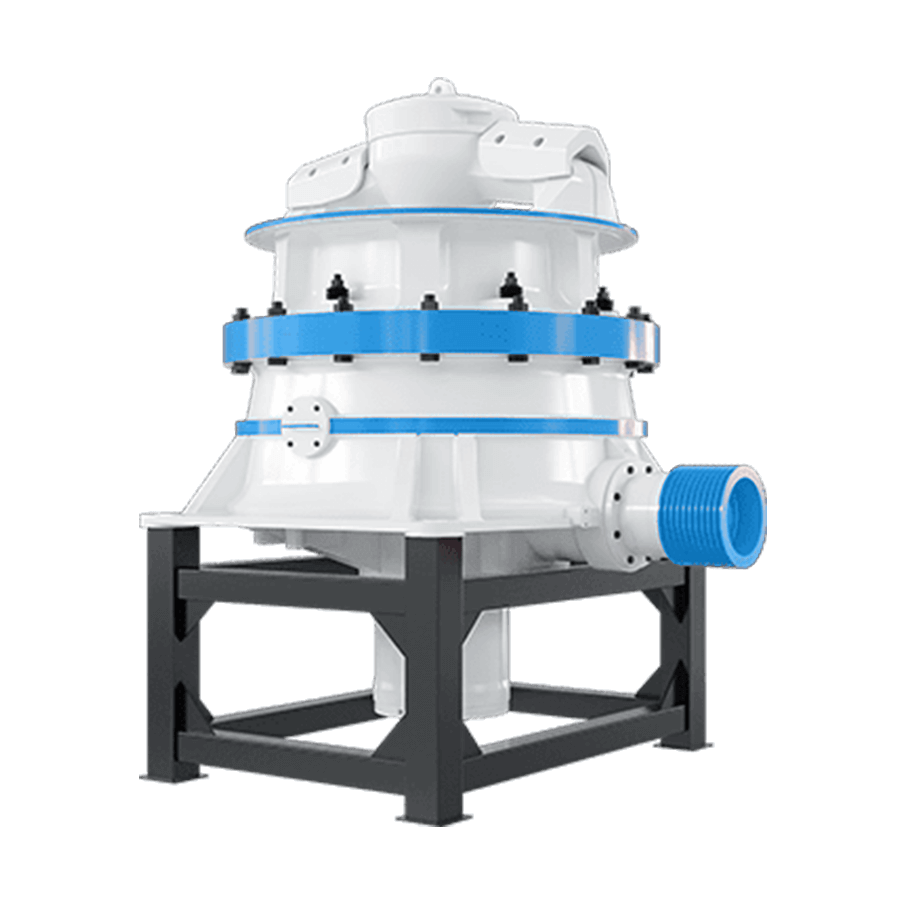

mobile cone crushing plant

The mobile cone crushing plant is mainly used for secondary or tertiary crushing processes. The machine has a better particle shape of the material output, and is especially suitable for fine crushing of various ores.

Capacity: 30-600 t/h

Feeding size: 50-300 mm

Voltage:220v/380v/415v/440v/480v

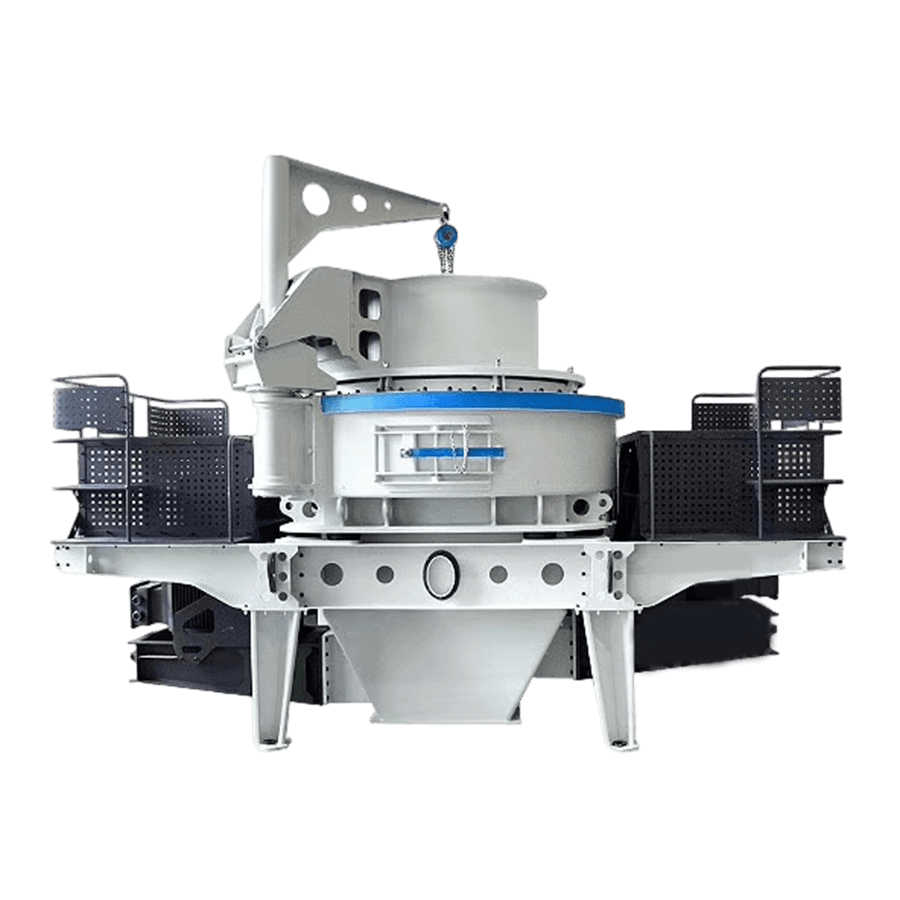

Mobile sand making plant

The mobile sand making plant is mainly a fully automatic sand and gravel production equipment that combines coarse crushing, fine crushing and screening equipment.

Capacity: 50-300 t/h

Feeding size: 1-750 mm

Voltage:220v/380v/415v/440v/480v

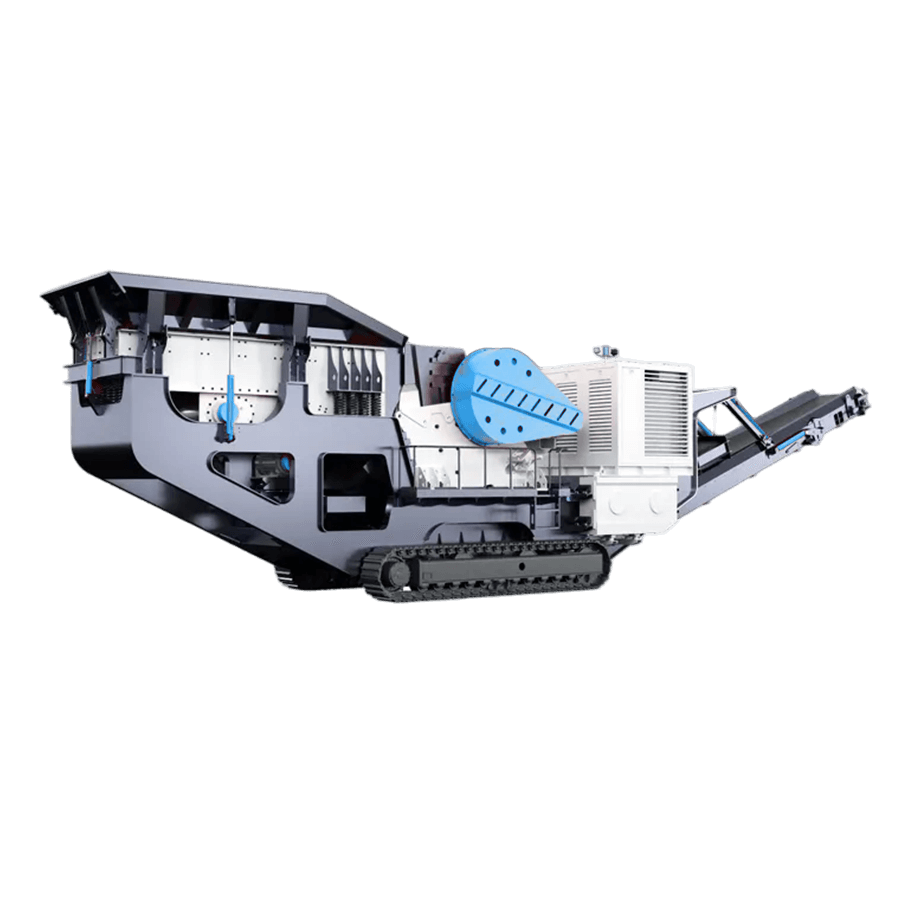

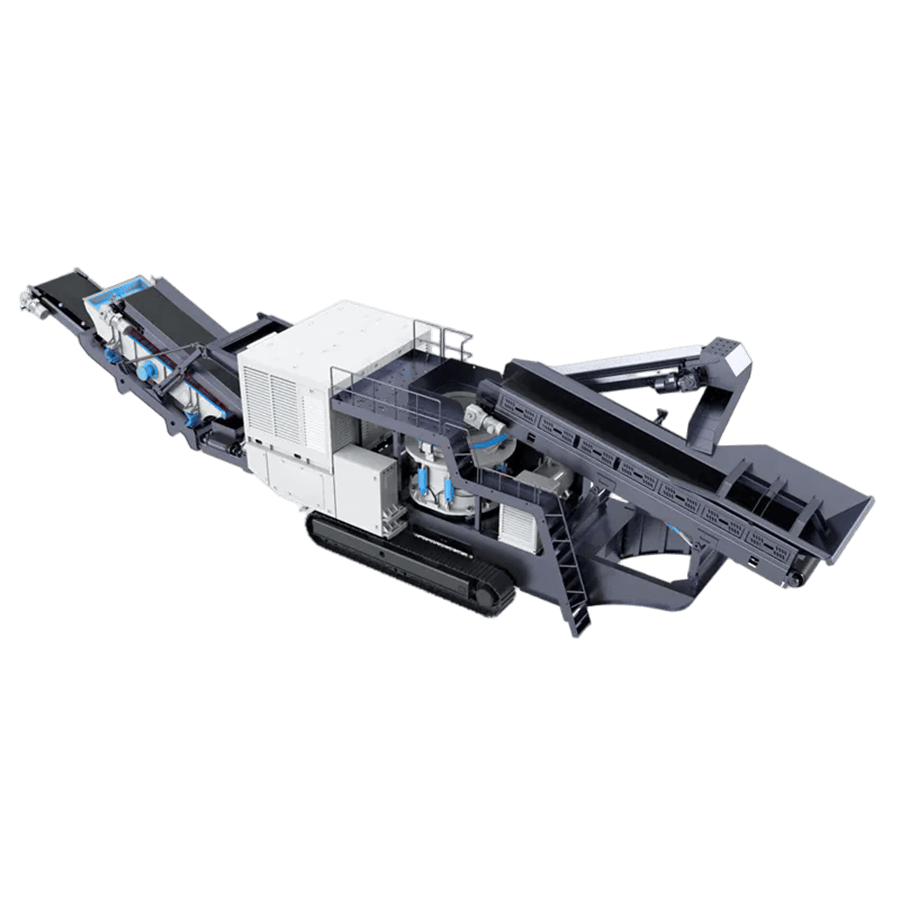

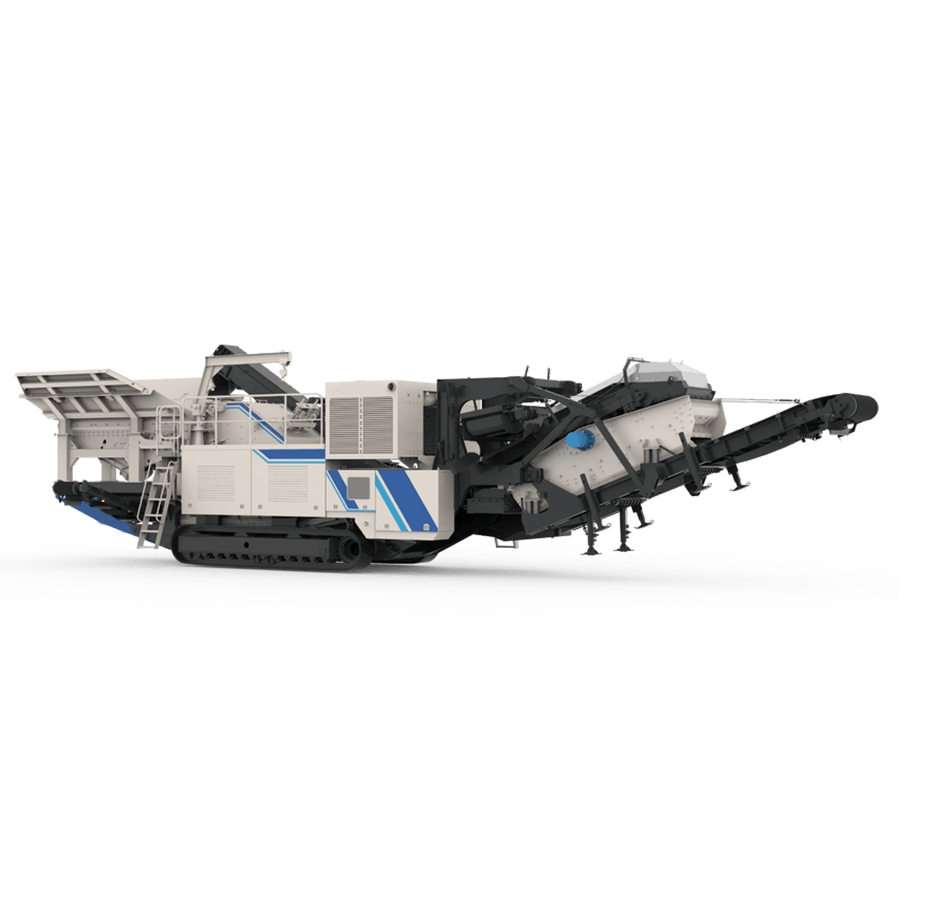

Crawler Type Mobile Crusher

The crawler crushing mobile plant is a highly integrated intelligent crushing equipment that integrates feeding, crushing, screening and conveying functions. With crawler chassis as the carrier, it has strong terrain adaptability, can move freely in complex environments such as mountains and wetlands, and can be quickly put into use without infrastructure.

The station is equipped with high-efficiency jaw crushers, impact crushers and other crushing equipment, which can perform multi-stage crushing of materials such as ores and construction waste.

Intelligent control system realizes precise operation and monitoring, with high production efficiency and low energy consumption. It is widely used in mining, road construction, urban solid waste treatment and other fields.

Crawler mobile jaw crushing plant

The crawler jaw mobile crushing plant uses crawler walking, and the main machine is equipped with a jaw crusher, which is mainly used for the coarse crushing process of various sand and gravel production lines.

Capacity: 60-700 t/h

Feeding size: 1-900 mm

Voltage:220v/380v/415v/440v/480v

Crawler mobile impact crushing plant

The crawler impact mobile crushing plant is equipped with an impact crusher, which is mainly used for the secondary or tertiary crushing process of various sand and gravel production lines.

Capacity: 50-700 t/h

Feeding size: 1-800 mm

Voltage:220v/380v/415v/440v/480v

Crawler mobile cone crushing plant

The crawler cone mobile crushing plant is equipped with a cone crusher (various cavity types), which is mainly used for the secondary or tertiary crushing process of various sand and gravel production lines.

Capacity: 50-450 t/h

Feeding size: 50-300 mm

Voltage:220v/380v/415v/440v/480v

Crawler mobile sand making plant

The crawler mobile sand making plant is a combined crushing and sand making equipment that integrates various crushers. The machine can effectively produce sand and gravel aggregates of various specifications through multiple crushing and screening.

Capacity: 50-300 t/h

Feeding size: 1-700 mm

Voltage:220v/380v/415v/440v/480v

Product Structure

The mobile crushing plant is mainly composed of supporting chassis, crushing equipment, feeding device, screening device, conveying system and control system, etc. The machine is easy to move and transfer, and can adapt to different working environments.

How it works

The working principle of a mobile crushing plant is similar to that of a fixed crusher, but it is more flexible and portable. The specific process is as follows:

Feeding: Materials enter the crusher from a mine or quarry through a vibrating feeder or a belt conveyor.

Crushing: Materials enter the crusher and are crushed into smaller particles after primary crushing (such as a jaw crusher) or secondary crushing (such as an impact crusher or a cone crusher).

Screening: The crushed materials pass through a screening system to separate the finished materials that meet the requirements, and the remaining materials continue to be crushed or screened again.

Transportation and stacking: The screened finished materials are transported to the stacking location or transport vehicle via a belt conveyor and transported to the next process or external sales.

The entire process can be completed in a mobile crushing station, which is simple and fast to operate, and can greatly save material transportation costs.

Application Areas

Mobile crushing plant is a highly efficient equipment integrating crushing, screening, conveying and automatic control, with the advantages of flexibility, cost saving and strong adaptability. The machine is widely used in the crushing of stone, ore and coal in the mining industry, the crushing of construction waste concrete, bricks and other materials, the production of sand and gravel aggregates in various road construction, the crushing of raw materials in cement plants, the crushing of ore in the metallurgical industry, and the resource utilization of environmental waste.

Product Advantages

1. Strong flexibility: The mobile crushing station can flexibly adjust the working position, reducing the trouble of material transportation and site relocation, and is particularly suitable for some construction sites with inconvenient roads and complex environments.

2. Save time and cost: Since it can be operated on-site, the transportation time and cost of materials from the mining site to the crushing site are reduced, and the impact of the environment on the production process is also reduced.

3. High efficiency: The mobile crushing station integrates crushing, screening, transportation and other functions, reducing the time of multiple material transportation and stacking, and has higher work efficiency.

4. Strong adaptability: The mobile crushing station is suitable for different material processing and can be customized for different ores or construction waste.

5. Low-cost operation: Due to the reduction of on-site installation and commissioning time, the operation and maintenance costs are also relatively low.

6. Environmental protection: The mobile crushing station adopts an advanced dust removal system to reduce dust pollution.

7. Multifunctional combination: According to user needs, the mobile crushing station can be equipped with different crushing equipment (such as jaw, impact, cone crusher), screening equipment and transportation system, and flexibly configured to meet the production needs of different output and particle size requirements.

Product Parameters

| Model | MC69 | MC7510 | MC9120 | MC1012 | MC1215 | MC1518 |

| Overall power (kW) | 118 | 138 | 187 | 209 | 264 | 342.5 |

| Operating Weight (t) | 33.5 | 41 | 44 | 53 | 41 | 48 |

| Capacity (t/h) | 80-330 | 110-350 | 120-430 | 160-450 | 80-280 | 100-350 |

| Feed bin | ||||||

| Volume(m3) | 6 | 6 | 7 | 7 | 6 | 7 |

| Width (mm) | 2900 | 2900 | 3000 | 3000 | 2900 | 3000 |

| Vibrating feeder | ||||||

| Model | GL9538 | GL9538 | GL1145A | GL1145A | GL9538 | GL1145A |

| Loading width (mm) | 950 | 950 | 1100 | 1100 | 950 | 1100 |

| Length (mm) | 3800 | 3800 | 4500 | 4500 | 3800 | 4500 |

| Crusher | ||||||

| Model | PE600x900 | PE750x1060 | PE900x1200 | PE1000x1200 | PE1200x1500 | PE1500x1800 |

| Motor power (kw) | 55 | 110 | 160 | 200 | 240 | 350 |

| Feed depth (mm) | 580 | 680 | 700 | 850 | ||

| Feed width (mm) | 930 | 980 | 1060 | 1100 | ||

| Maximum feeding (mm) | 480 | 560 | 560 | 700 | 500 | 600 |

| Discharge port (mm) | 60-175 | 75-175 | 70-200 | 100-200 | >30 | >30 |

| Conveyor | ||||||

| Main conveyor | B1000 | B1000 | B1200 | B1200 | B1000 | B1200 |

| Side exit conveyor(optional) | B650 | B650 | B650 | B650 | B650 | B650 |

| The above are only some models of mobile crushing plants. Please consult our company for more types of mobile crushing plants. | ||||||

Have you decided on the model you want to buy? If you can’t find the model you want, please contact us for consultation.

More related cases

The mobile crushing plant produced by Henan Reacore is often used in the crushing operations of mining, metallurgy, construction, highway, railway, cement, and construction waste industries. The machine can walk on the work site, greatly improving work efficiency.

Why Choose Us

We have a professional team of engineers who can design and manufacture production solutions according to your needs.

We have a professional modern production workshop, and all the equipment leaving the factory has been quality inspected.

We have many years of manufacturing experience, all equipment is independently developed and produced, the price is more favorable.

We provide a full range of technical support and can provide you with high-quality purchasing services and after-sales services.

More related products you may want to know

contact us for quote

You can tell us your needs from the following aspects:

1. What is the product name and model you want to know?

2. What type of project do you plan to buy our equipment for?

3. When will you start this project?

4. Where will you carry out your project?

If you don’t know how to choose a specific product, or you need a special project design solution, you can leave your contact information and our technical engineers will design a special solution for you.