Stone Crushing Plant For Sale

Applicable materials:

Iron ore, copper ore, gold ore, phosphate ore, silica ore, gypsum, granite, basalt, limestone, marble, quartz, pebbles, concrete blocks, bricks, waste brick slag, etc.

Feeding size: 150-1500 mm

Power: 5.5-220* Kw

Capcity: 1-800 T/h

What is a stone crushing plant

The stone crushing line is also called the aggregate crushing production line. It mainly produces finished products such as construction sand, aggregate, mineral powder, etc. of various particle sizes that meet the needs after a series of crushing and screening of large rocks or ores and other raw materials.

Stone crushing production lines are widely used in mining, construction, roads, cement, metallurgy and other industries. They are important equipment that is indispensable in modern construction and infrastructure construction.

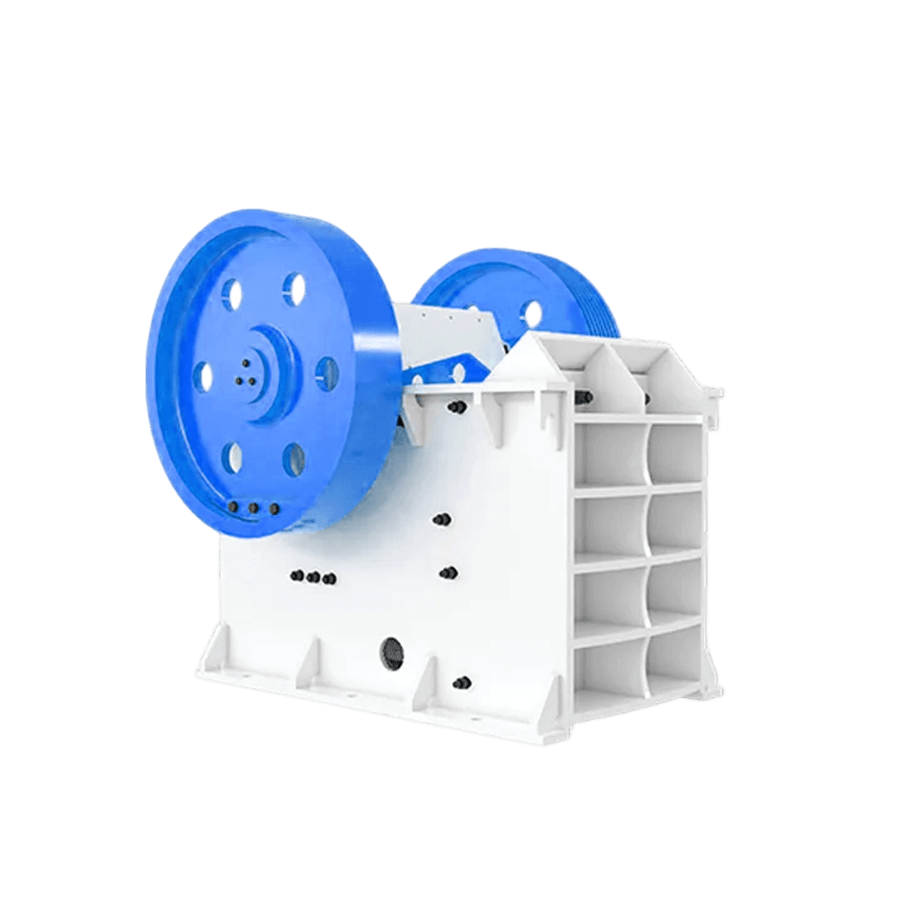

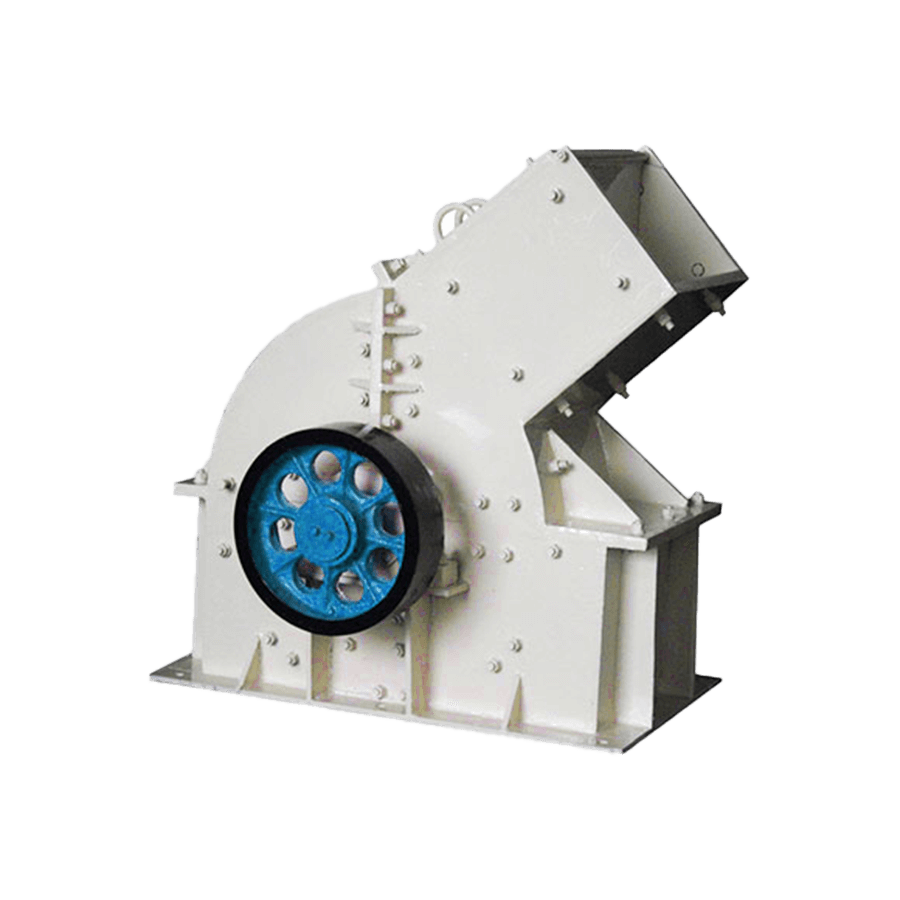

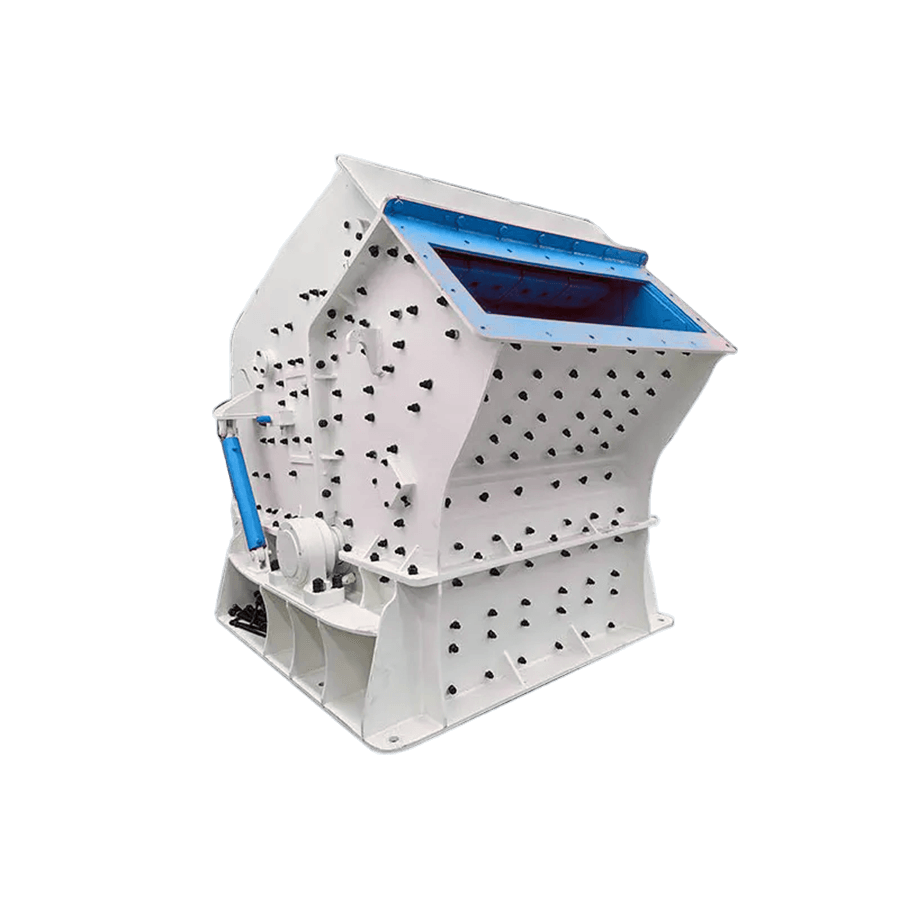

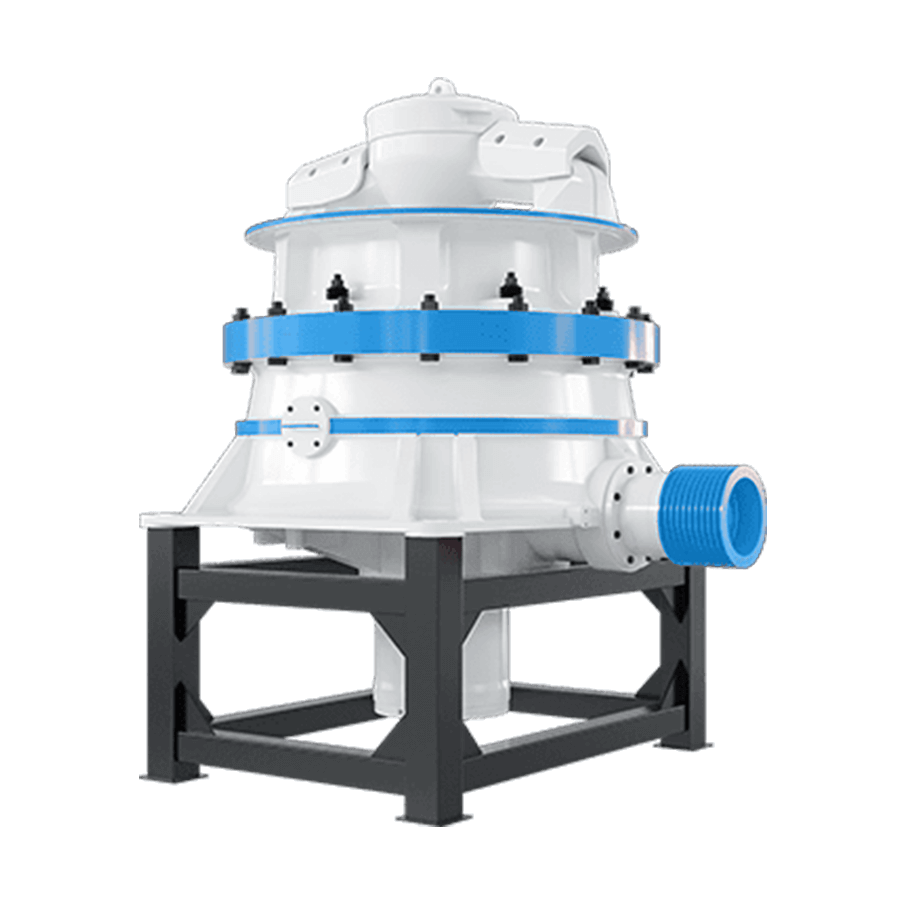

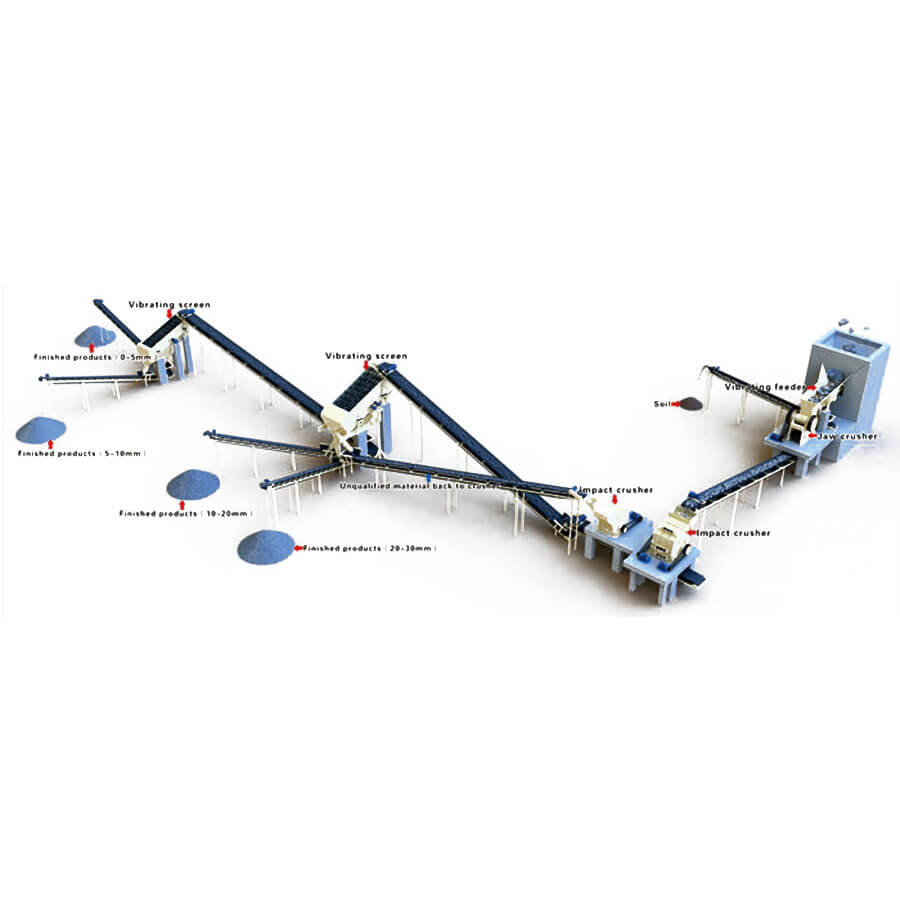

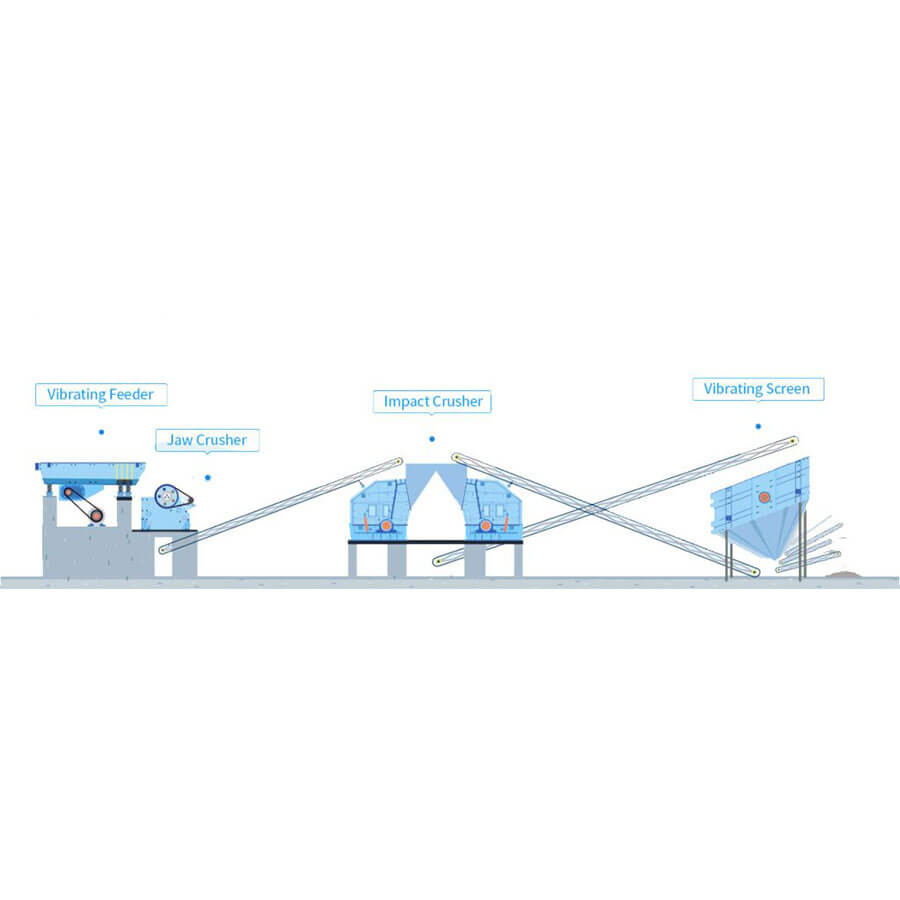

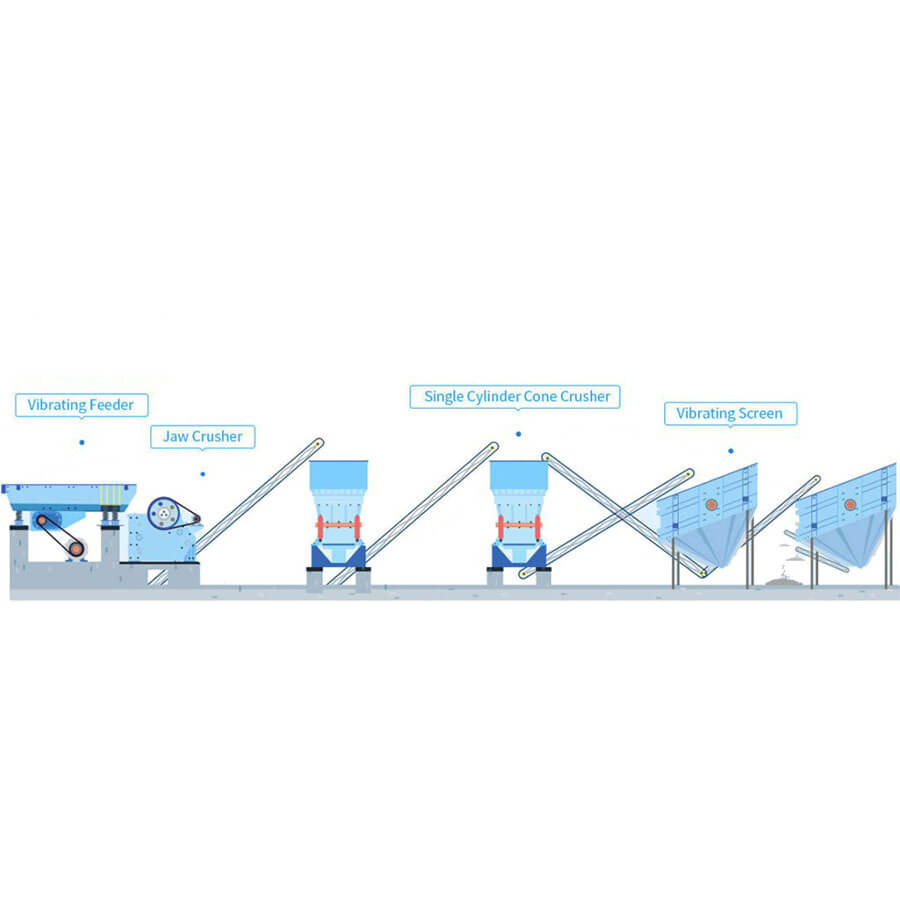

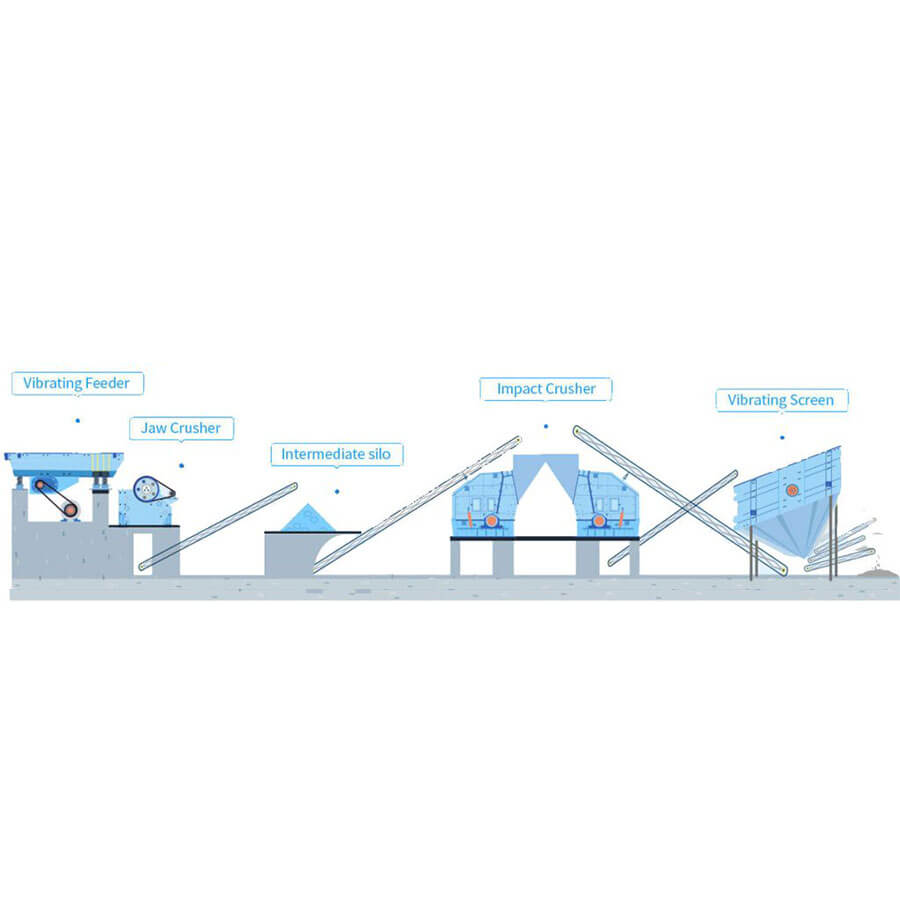

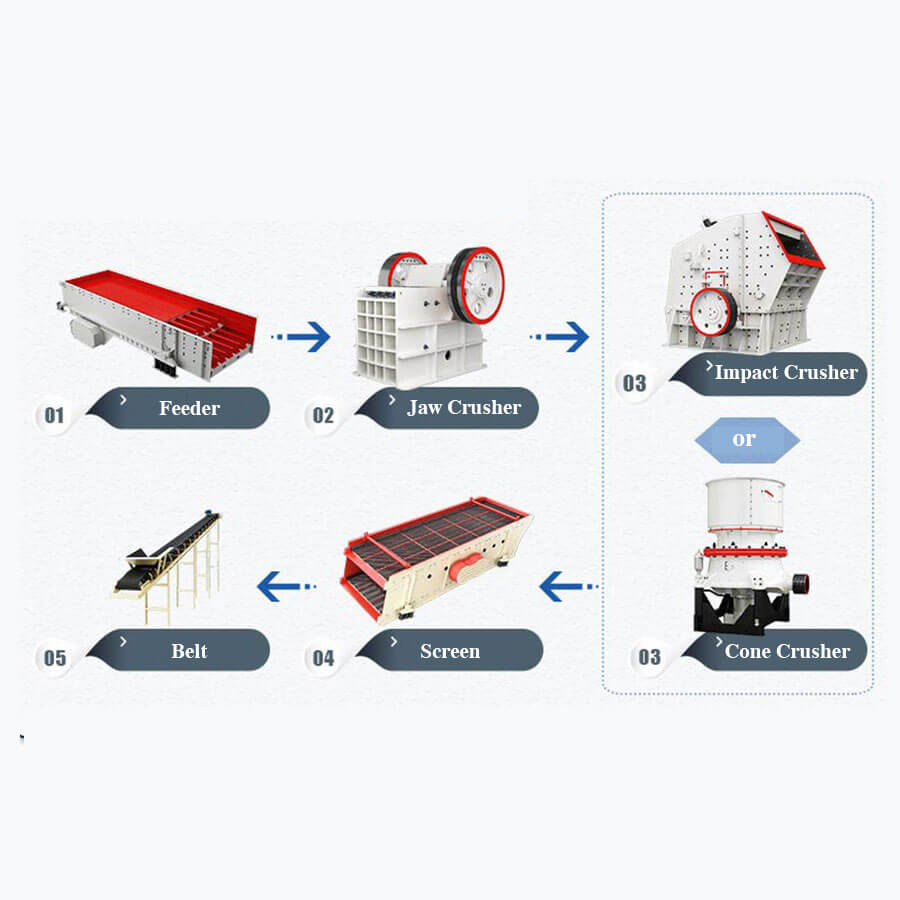

It is usually composed of vibrating feeder, crusher (such as jaw crusher, impact crusher, etc.), screening equipment, belt conveyor, etc. The raw materials are evenly transported to the crusher for multi-stage crushing by the feeder, and then screened and graded by the screening machine. Unqualified aggregates are returned for re-crushing, and qualified aggregates are transported to the finished product pile by the belt conveyor, realizing automated and continuous production to meet the aggregate needs of construction, road and other projects.

Types of stone crushing plant We Sale

The stone crushing plants produced by Henan Reacore have different configurations according to different capacity requirements. The following are several common configurations:

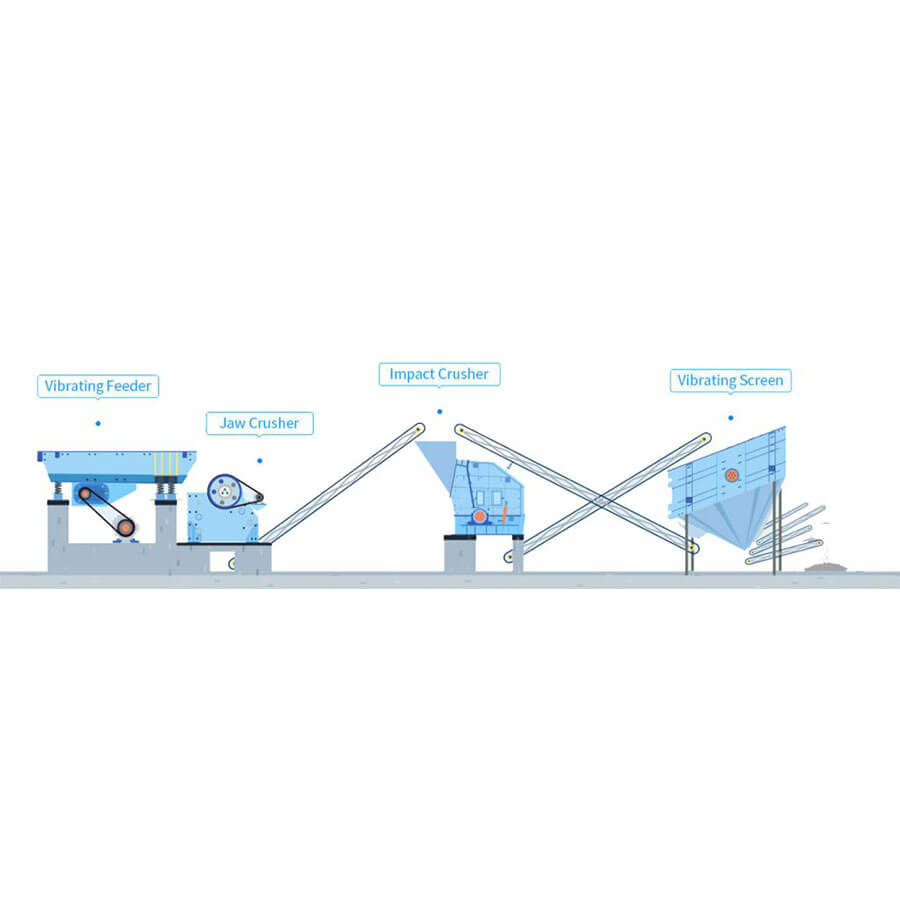

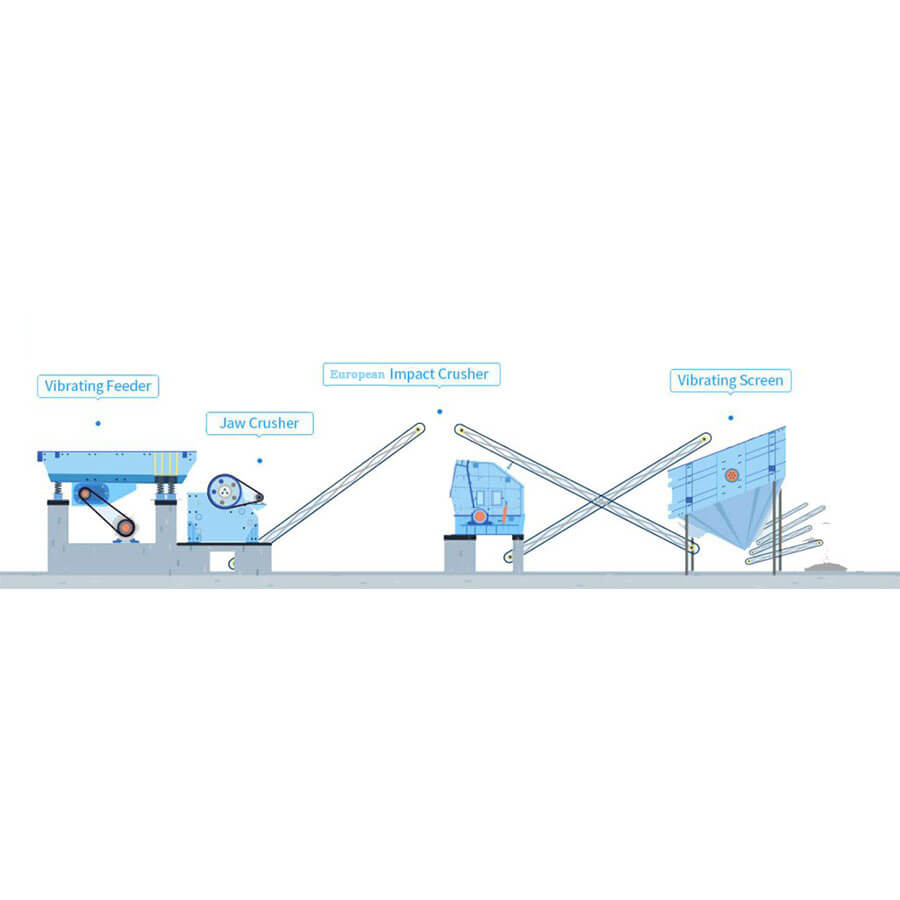

Small production line: suitable for projects with small annual output and low particle size requirements, generally equipped with jaw crushers, impact crushers and vibrating screens.

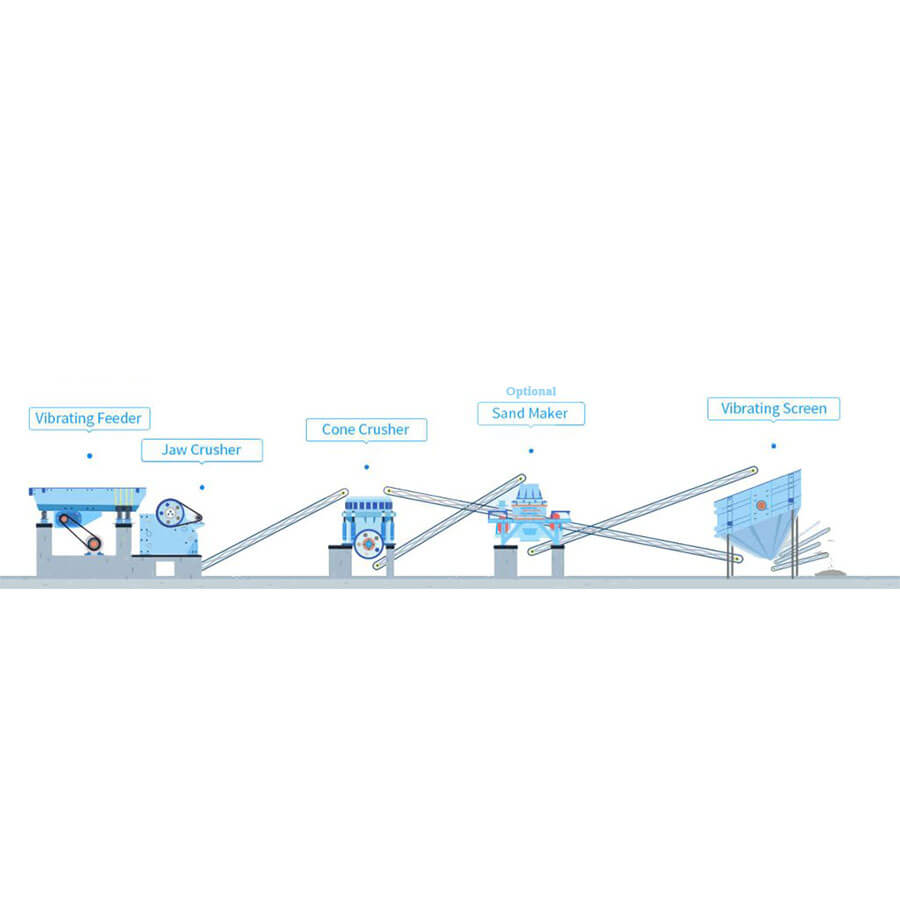

Medium production line: suitable for medium annual output, the output sand and gravel aggregates need to have certain strength and particle size requirements, equipped with jaw crushers, cone crushers, vibrating screens and belt conveyors.

Large production line: suitable for projects with large annual output and high processing difficulty, often using two-stage crushing (jaw crusher + cone crusher) or three-stage crushing process, equipped with more screening and conveying equipment.

Small Capacity Stone Crushing Plant

The small-capacity stone crushing production line manufactured by Henan Reacore adopts jaw crusher + impact crusher as the main crushing machine, with a capacity of 10-150t/h. The machine model can be changed according to customer needs to increase production.

10-20t/h stone crushing plant

The production line is configured as follows: GZD750x2500 vibrating feeder, PE250x400 jaw crusher, 2YK1237 vibrating screen.

Capacity: 10-20 t/h

Feeding size: 1-200 mm

Voltage:220v/380v/415v/440v/480v

30-50t/h stone crushing plant

The production line is configured as follows: GZD750x2500 vibrating feeder, PE400x600 jaw crusher, PF1010 impact crusher, 2YK1237 vibrating screen.

Capacity: 30-50 t/h

Feeding size: 1-300 mm

Voltage:220v/380v/415v/440v/480v

50-150t/h stone crushing plant

The production line is configured as follows: GZD960x3800 vibrating feeder, PE750x1060 jaw crusher, PF1214 or RS1315 impact crusher, 2YK1860 vibrating screen.

Capacity: 50-150 t/h

Feeding size: 1-500 mm

Voltage:220v/380v/415v/440v/480v

Medium Capacity Stone Crushing Plant

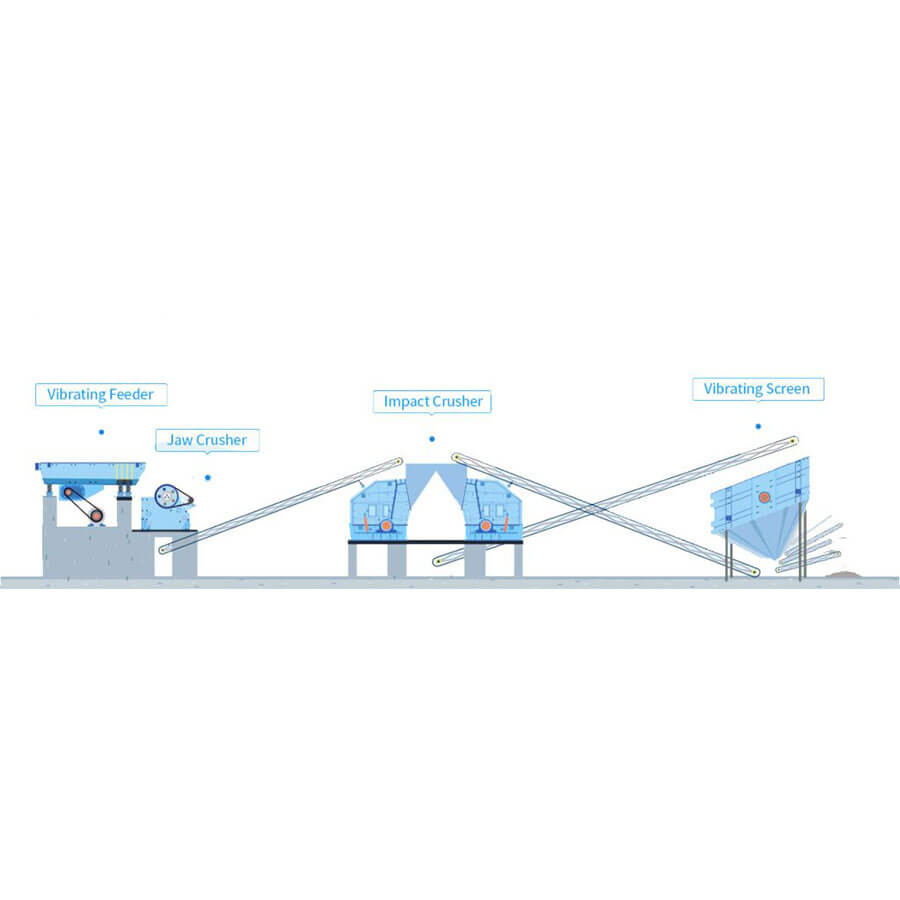

The medium-sized stone crushing production line produced by Henan Reacore uses jaw crusher + impact crusher or cone crusher as the main crushing equipment, with an output of 150-500t/h. The machine model can be replaced according to customer needs to increase the output.

150-200t/h stone crushing plant

The production line is configured as follows: GZD960x3800 vibrating feeder, PE750x1060 jaw crusher, PYB200 cone crusher, 2YK1860 vibrating screen.

Capacity: 150-200 t/h

Feeding size: 1-550 mm

Voltage:220v/380v/415v/440v/480v

200-300t/h stone crushing plant

The production line is configured as follows: GZD960x3800 vibrating feeder, PE750x1060 jaw crusher, two PF1210 imapct crusher, 2YK1860 vibrating screen.

Capacity: 200-300 t/h

Feeding size: 1-650 mm

Voltage:220v/380v/415v/440v/480v

300-500t/h stone crushing plant

The production line is configured as follows: one GZD960x3800 vibrating feeder, one PE1000x1200 jaw crusher, two PF1315 impact crushers, and 2YK2460 vibrating screens.

Capacity: 300-500 t/h

Feeding size: 1-750 mm

Voltage:220v/380v/415v/440v/480v

Large Capacity Stone Crushing Plant

The Large-scale stone crushing production line produced by Henan Reacore uses jaw crusher + impact crusher or cone crusher as the main crushing equipment. The specific machine configuration can be carried out according to the actual site and needs of the user, with an output of 500-1000t/h, which is suitable for various large-scale projects.

500-800t/h stone crushing plant

The production line is configured as follows: one GZD1500x6000 vibrating feeder, one PE1200x1500 jaw crusher, one CH660 single-cylinder hydraulic cone crusher, and 2YK2460 vibrating screen.

Capacity: 500-800 t/h

Feeding size: 1-1000 mm

Voltage:220v/380v/415v/440v/480v

800-1000t/h stone crushing plant

The production line is configured as follows: one GZD1500x6000 vibrating feeder, one PE1500x1800 jaw crusher, one RS1620 impact crusher, and 2YK3072 vibrating screen.

Capacity: 800-1000 t/h

Feeding size: 1-1000 mm

Voltage:220v/380v/415v/440v/480v

Product Structure

Stone crushing plants usually consist of the following parts:

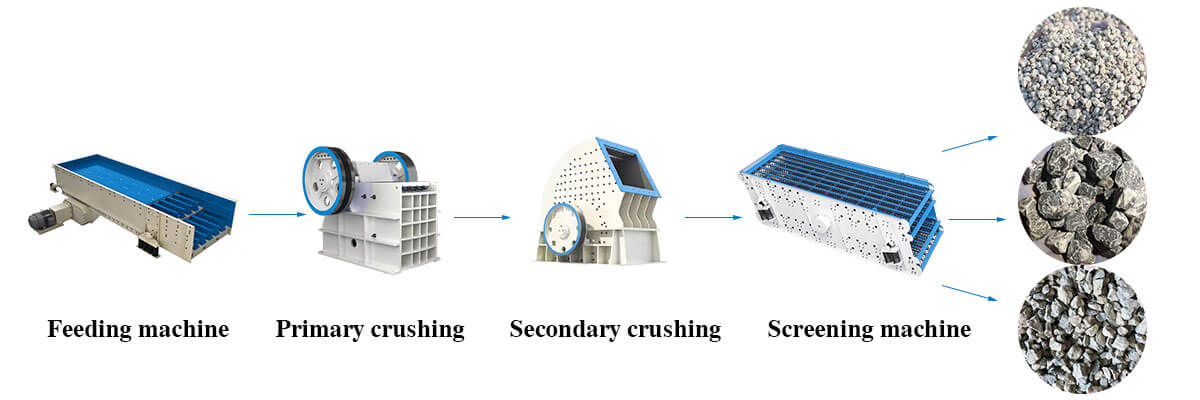

Feeding system: including vibrating feeder, belt conveyor, etc., used to evenly feed raw materials into the crushing equipment.

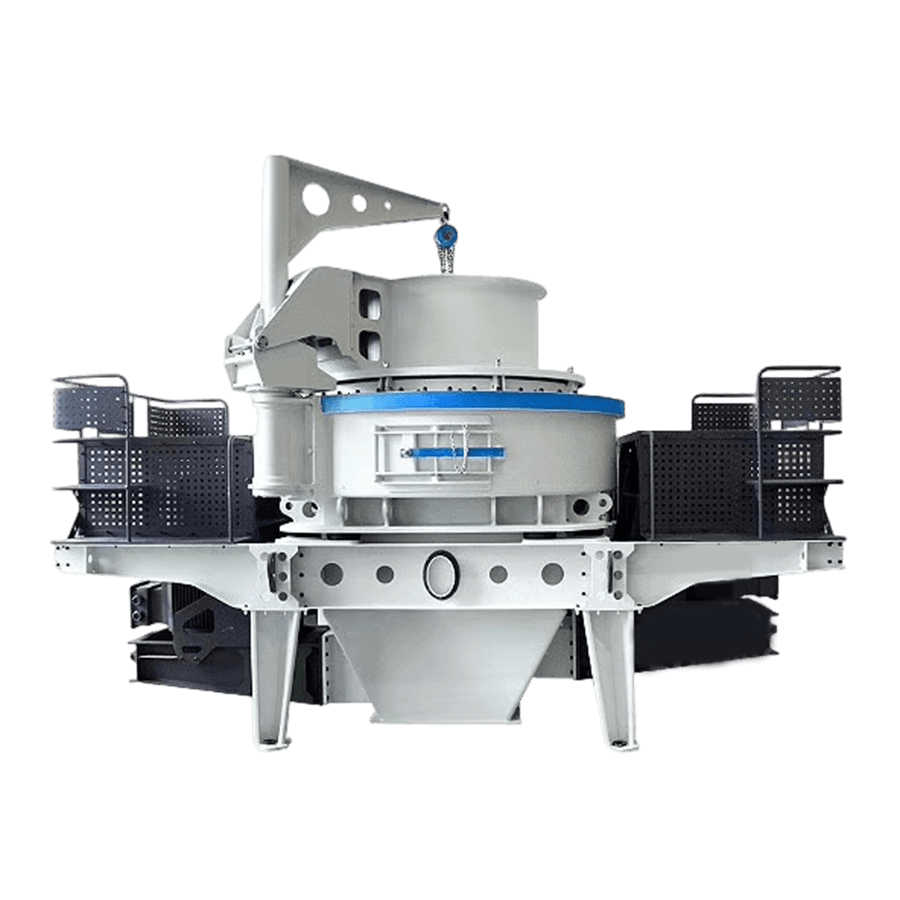

Crushing system: including coarse crushing equipment (such as jaw crusher), medium crushing equipment (such as impact crusher or cone crusher), fine crushing equipment (such as VSI crusher or fine crushing cone crusher).

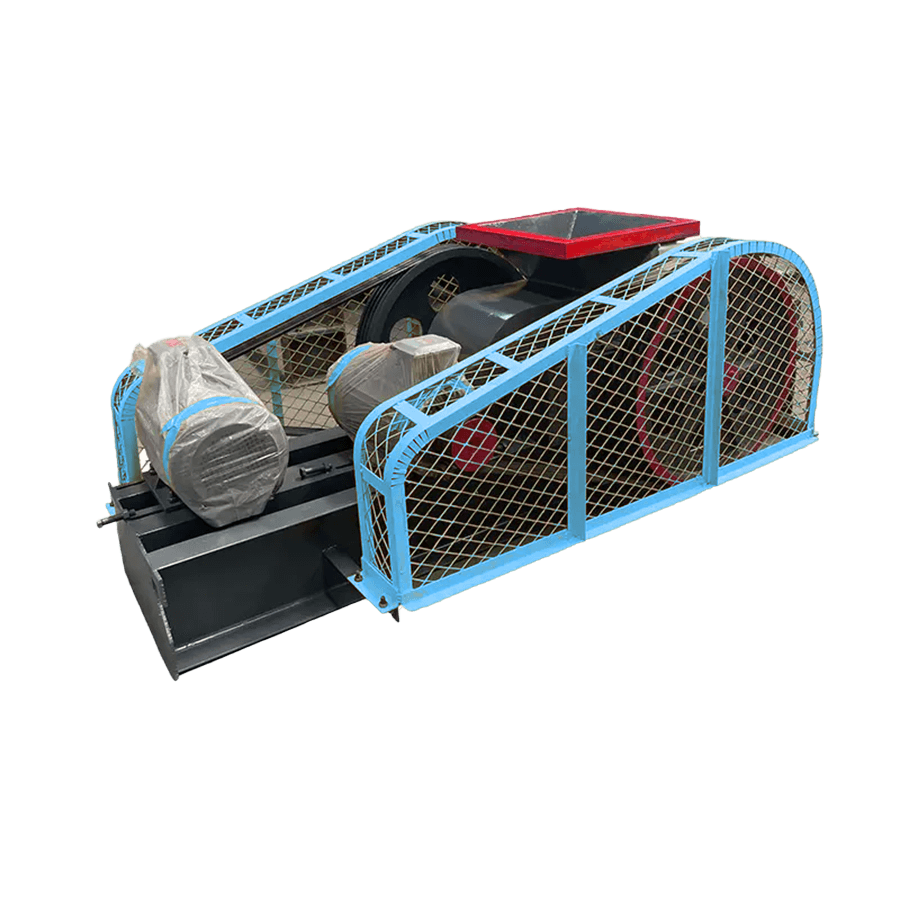

Screening system: usually including vibrating screen, used to screen the crushed materials and separate finished products of different particle sizes.

Conveying system: including belt conveyor, which transports the crushed materials to the designated production link or finished product warehouse.

Electronic control system: responsible for automatic control and management of the operation of the entire production line to ensure coordinated operation of the equipment.

Dust removal system: some production lines with high environmental protection requirements are equipped with dust removal equipment to reduce dust pollution.

How it works

When the aggregate crushing production line is in operation, the vibrating feeder evenly feeds the raw materials into the crusher. The crusher crushes the raw materials by using the principles of extrusion and impact. The crushed materials are sent to the vibrating screen by the belt conveyor. The screen classifies the materials according to different particle sizes. The qualified aggregates are output as finished products, and the unqualified ones are returned to the crusher by the belt conveyor for re – crushing. This cycle realizes the continuous production and specification control of aggregates.

Application Areas

The stone crushing production line crushes raw materials into finished aggregates of different sizes in an efficient and automated way. It is an important equipment in the mining, construction, road construction and other industries. Henan Reacore produces stone crushing plants with high efficiency, environmental protection and energy saving, which play an irreplaceable role in modern production.

Product Advantages

1. High efficiency: The whole production line equipment works efficiently and can process a large amount of materials with high yield and efficiency to meet large-scale production needs.

2. High degree of automation: Most modern stone crushing production lines are equipped with PLC control systems, which can realize automatic operation, reduce manual intervention, and ensure the stability of production.

3. Simple operation: The equipment operation interface is friendly, easy to master, and suitable for most operators.

4. Uniform product size: By reasonably configuring crushing equipment and screening equipment, finished products with uniform particle size and good quality can be produced.

5. Good environmental performance: Many stone crushing production lines are equipped with dust removal devices and noise control systems to effectively reduce pollution to the environment.

6. Low energy consumption: The design of modern stone crushing equipment focuses on energy efficiency and energy saving, which can reduce energy consumption and operating costs while producing efficiently.

7. Wide application: The stone crushing production line can process various types of ores, such as granite, limestone, marble, sandstone, river pebbles, etc., to meet the needs of different fields.

8. Strong equipment durability: Made of high-quality materials and advanced technology, the equipment is guaranteed to have good durability and long service life.

Product Parameters

| Capacity(t/h) | 10-20 | 20-50 | 50-100 | 100-300 | 300-500 | ≥500 |

| Feeder | GZD750x2500 | GZD750x2500 | GZD850x3000 | GZD960x3800 | GZD1100x4200 | GZD1300x4900 |

| Primary crusher | PE250x400 | PE400x600 | PE500x750 | PE750xl060 | PE1000x1200 | PEl200x1500 |

| Fine Crusher | / | PF1010 | PF1210 | PF-1214 | PF-1315 | RS1620 |

| Screening Machine | 2YK1237 | 2YK1237 | 2YK1548 | 2YK1860 | 2YK2460 | 2YK3072 |

| The above parameters are for reference only. If you need detailed parameters, please contact us. | ||||||

Have you decided on the model you want to buy? If you can’t find the model you want, please contact us for consultation.

More related cases

The stone crushing plant produced by Henan Reacore is your best choice whether it is used for crushing operations in mining, metallurgy, construction, highway, railway, cement industry, or secondary crushing of construction waste bricks.

Why Choose Us

We have a professional team of engineers who can design and manufacture production solutions according to your needs.

We have a professional modern production workshop, and all the equipment leaving the factory has been quality inspected.

We have many years of manufacturing experience, all equipment is independently developed and produced, the price is more favorable.

We provide a full range of technical support and can provide you with high-quality purchasing services and after-sales services.

More related products you may want to know

contact us for quote

You can tell us your needs from the following aspects:

1. What is the product name and model you want to know?

2. What type of project do you plan to buy our equipment for?

3. When will you start this project?

4. Where will you carry out your project?

If you don’t know how to choose a specific product, or you need a special project design solution, you can leave your contact information and our technical engineers will design a special solution for you.