Sand Crushing Plant For Sale

Applicable materials:

Iron ore, copper ore, gold ore, phosphate ore, silica ore, gypsum, granite, basalt, limestone, marble, quartz, pebbles, concrete blocks, bricks, waste brick slag, etc.

Feeding size: 150-1500 mm

Power: 5.5-220* Kw

Capcity: 1-800 T/h

What is a sand crushing plant

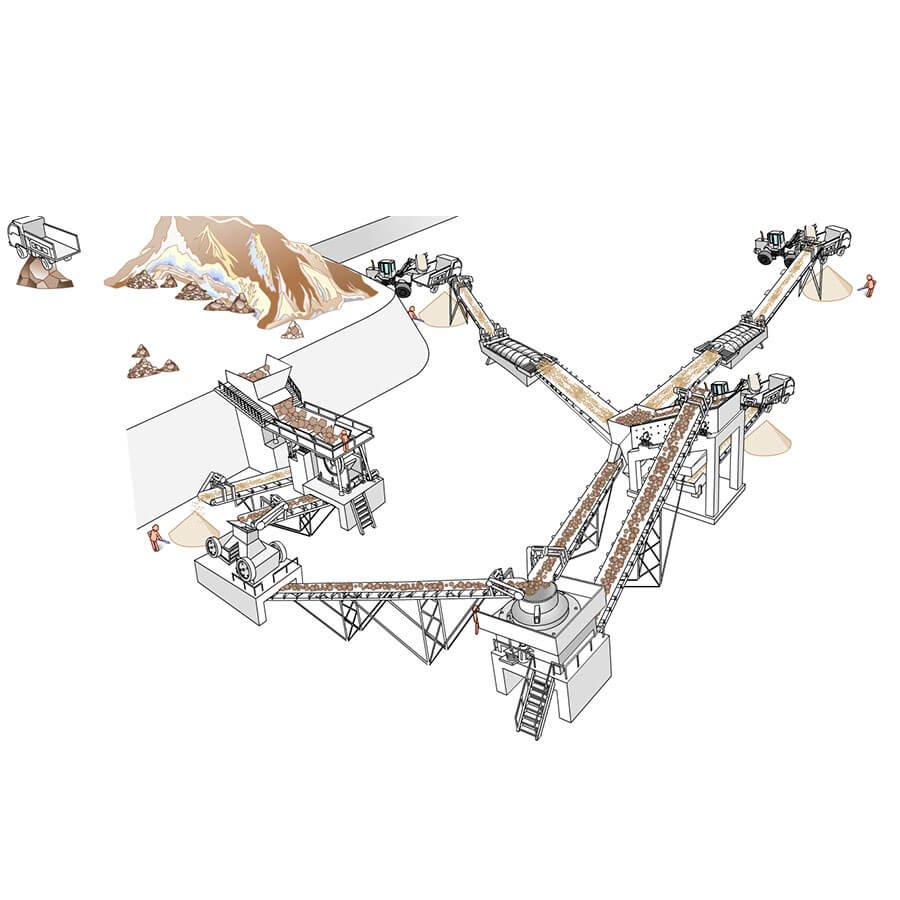

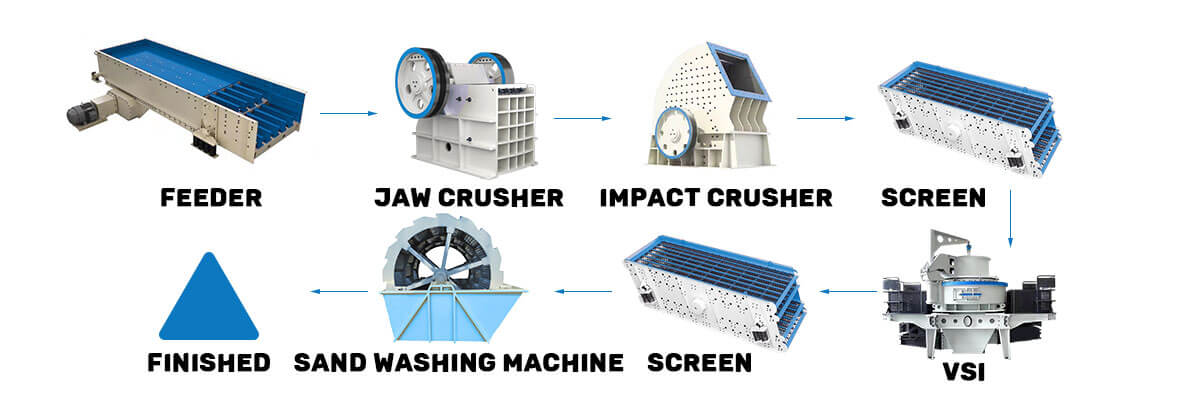

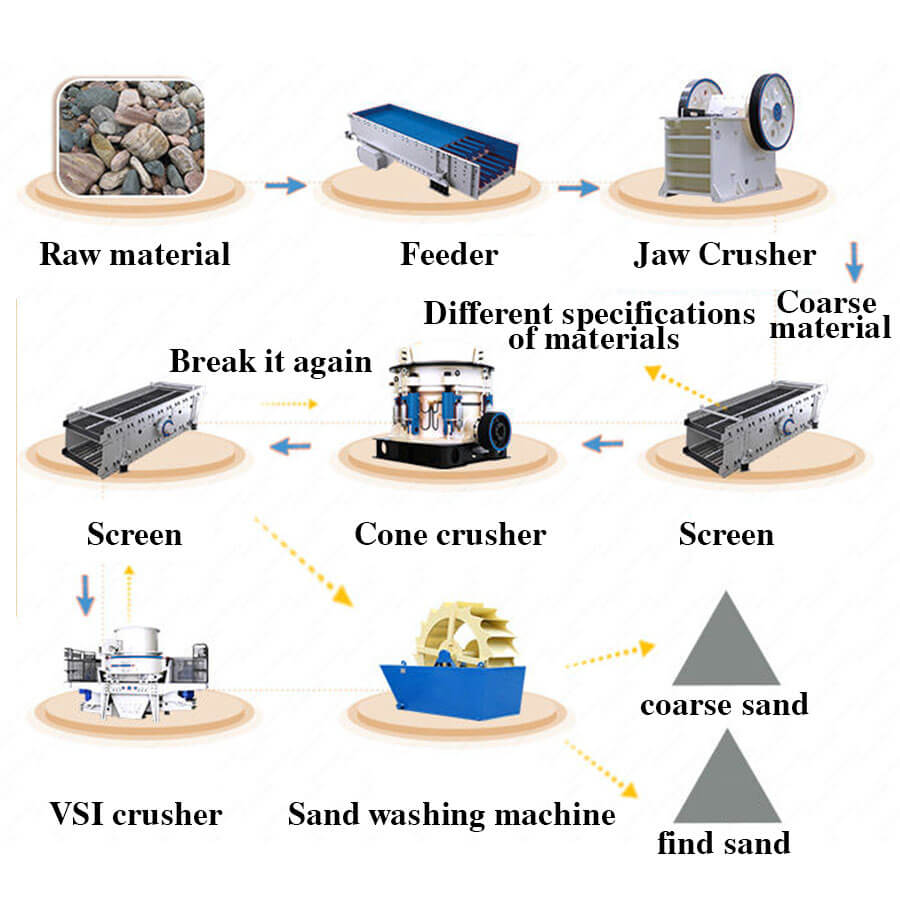

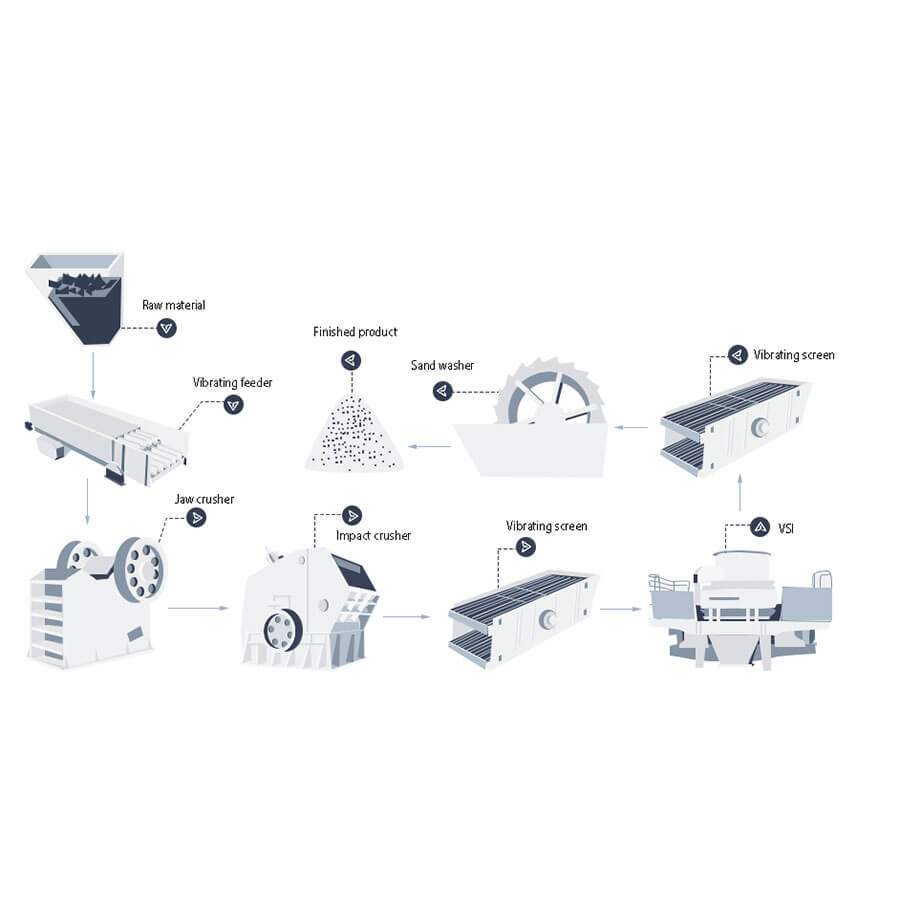

The sand making and crushing production line is a professional equipment combination for processing various ores, rocks and other raw materials into construction sand. The production line mainly consists of vibrating feeders, crushers, sand – making machines, vibrating screens, sand washing machines and belt conveyors.

Raw materials are fed into the crusher for primary crushing, then further finely crushed and shaped by the sand – making machine. The vibrating screen screens out qualified sand, and the sand washing machine removes impurities. Finally, the finished products are transported by the belt conveyor. The production line enables automated continuous production, efficiently producing machine – made sand with uniform particle size and high cleanliness to meet the needs of construction and infrastructure industries.

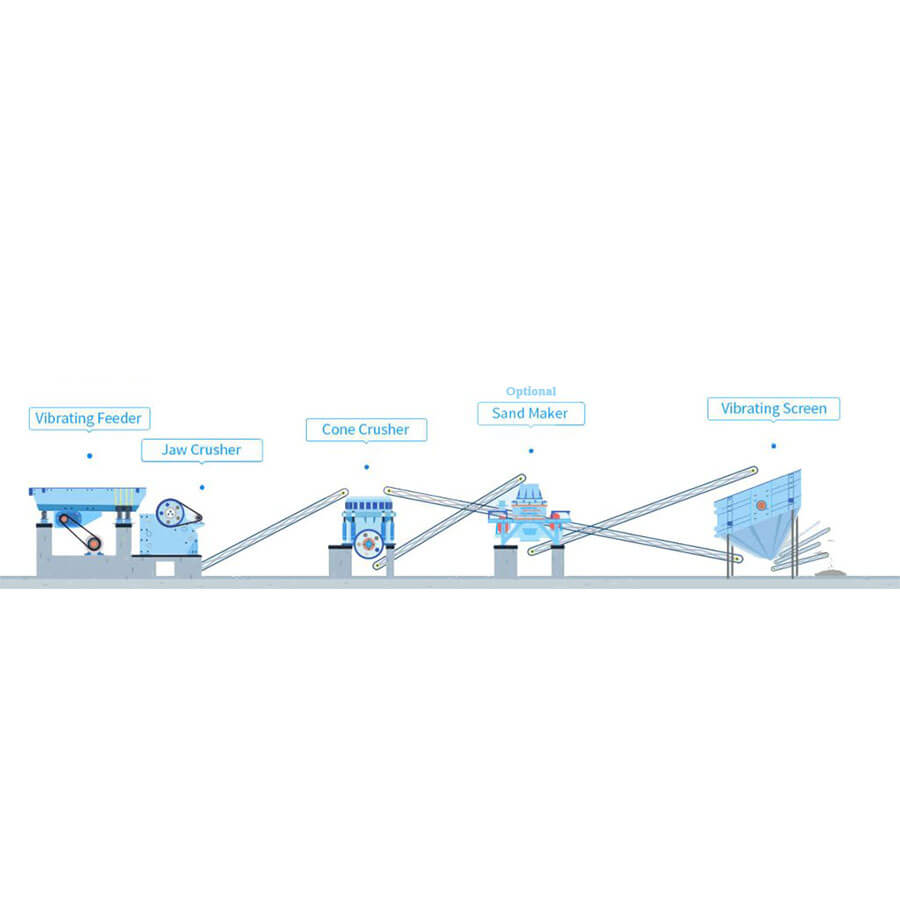

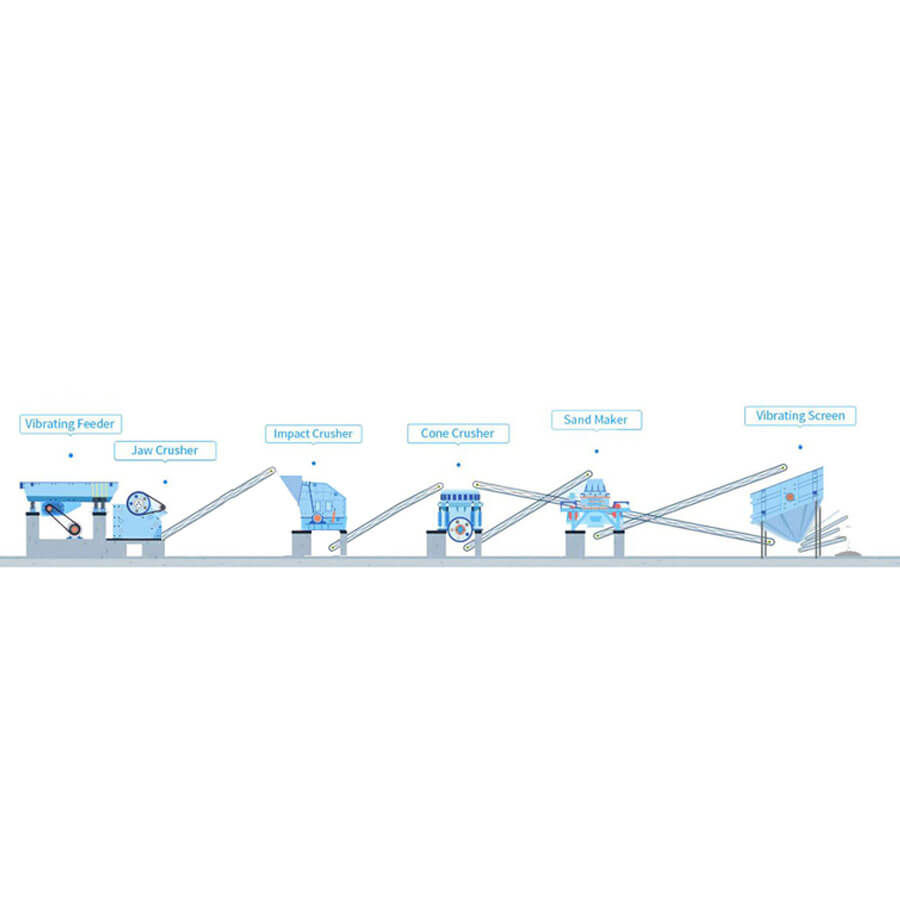

Types of sand crushing plant We Sale

The sand crushing plant produced by Henan Reacore adopt different configurations according to different production capacity requirements. The following are several common configurations:

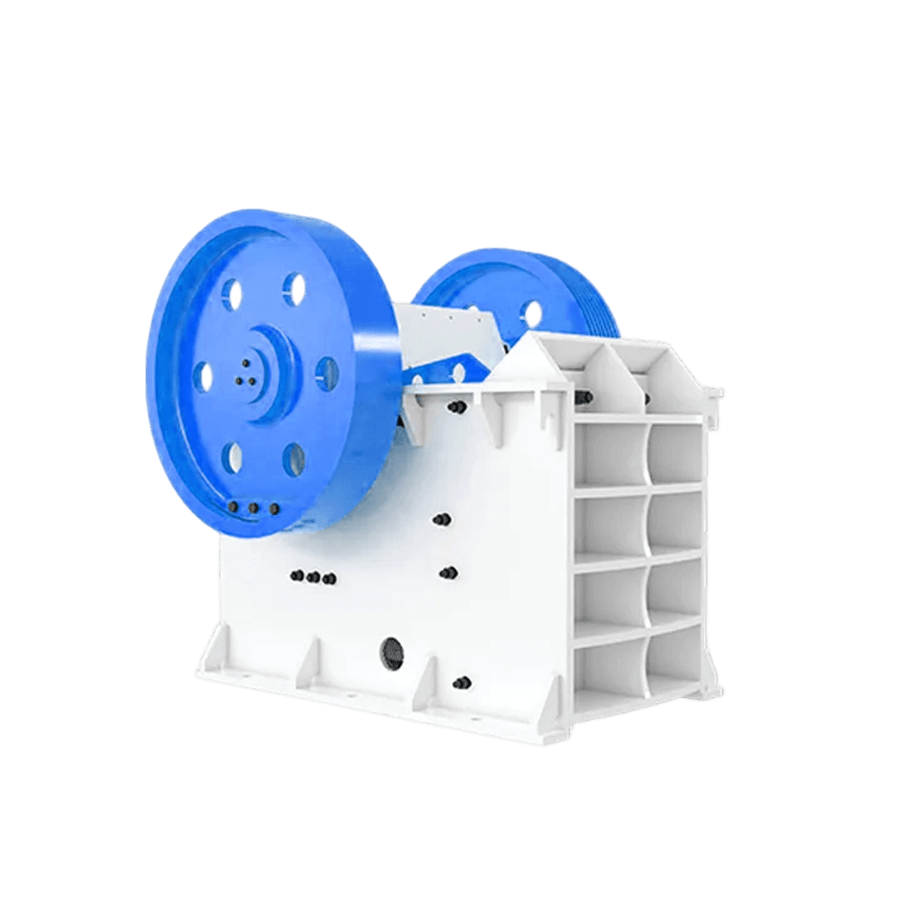

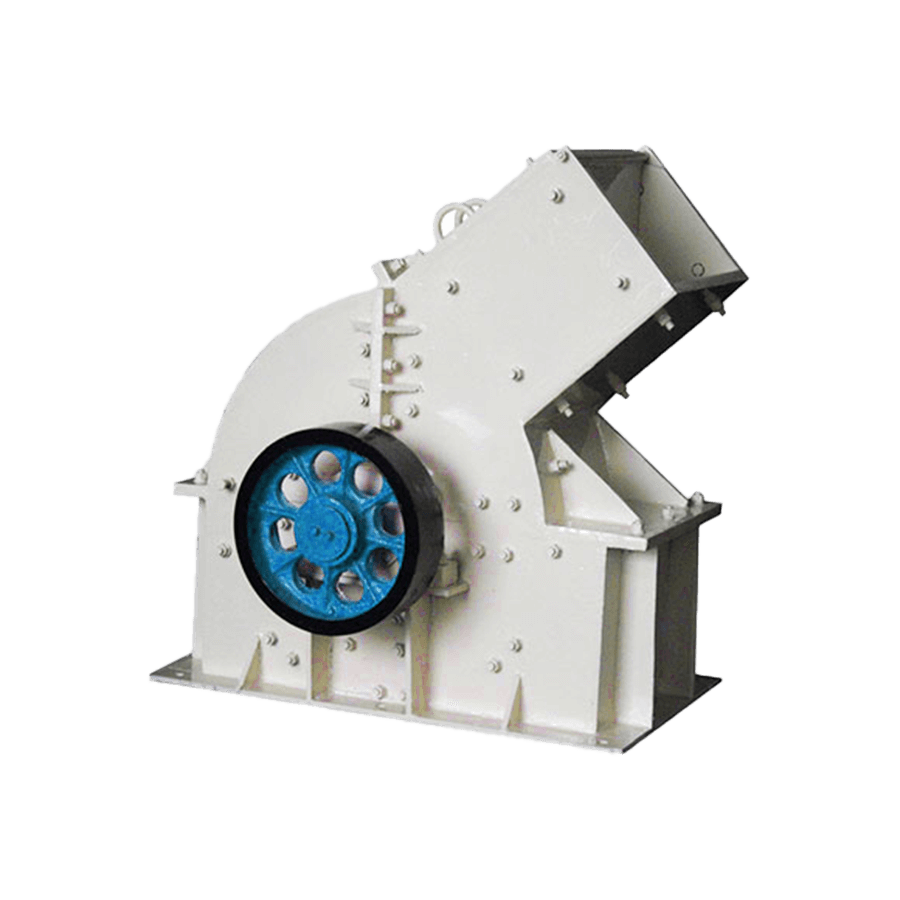

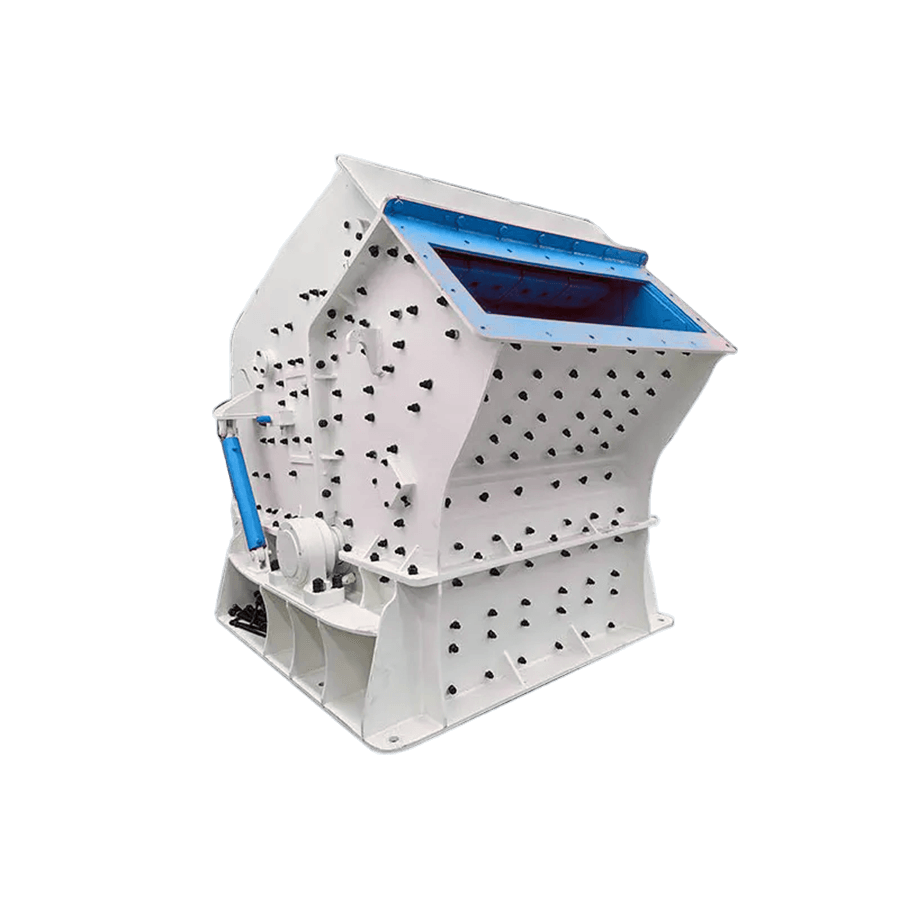

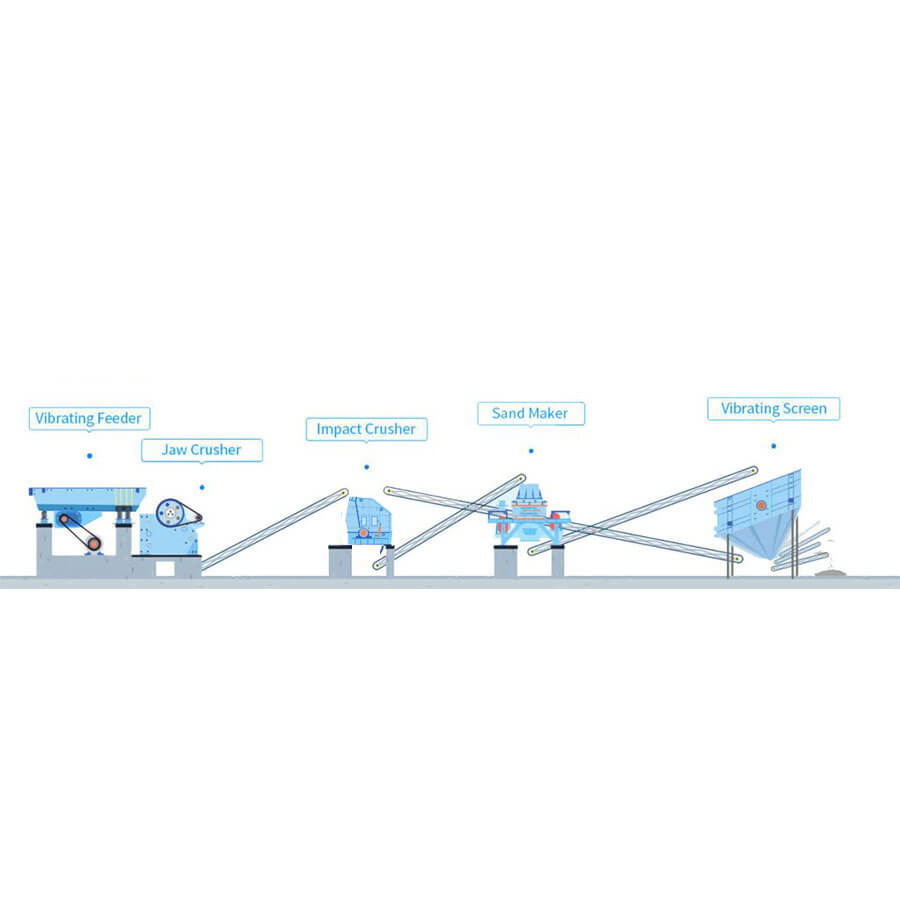

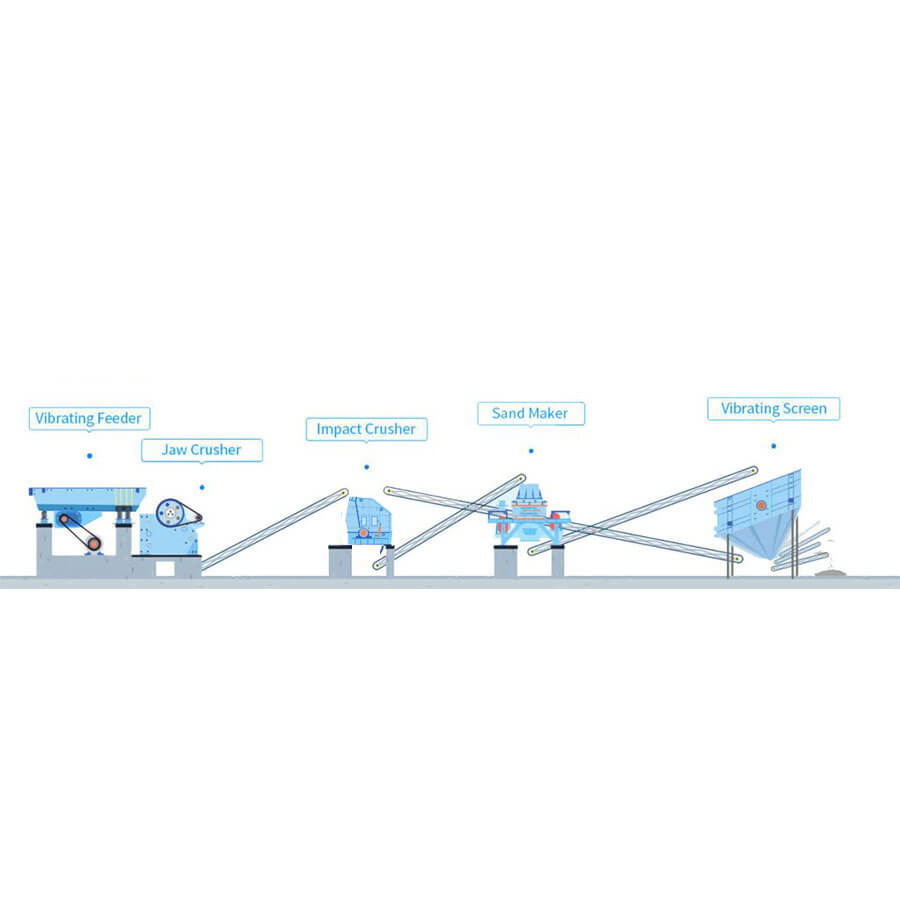

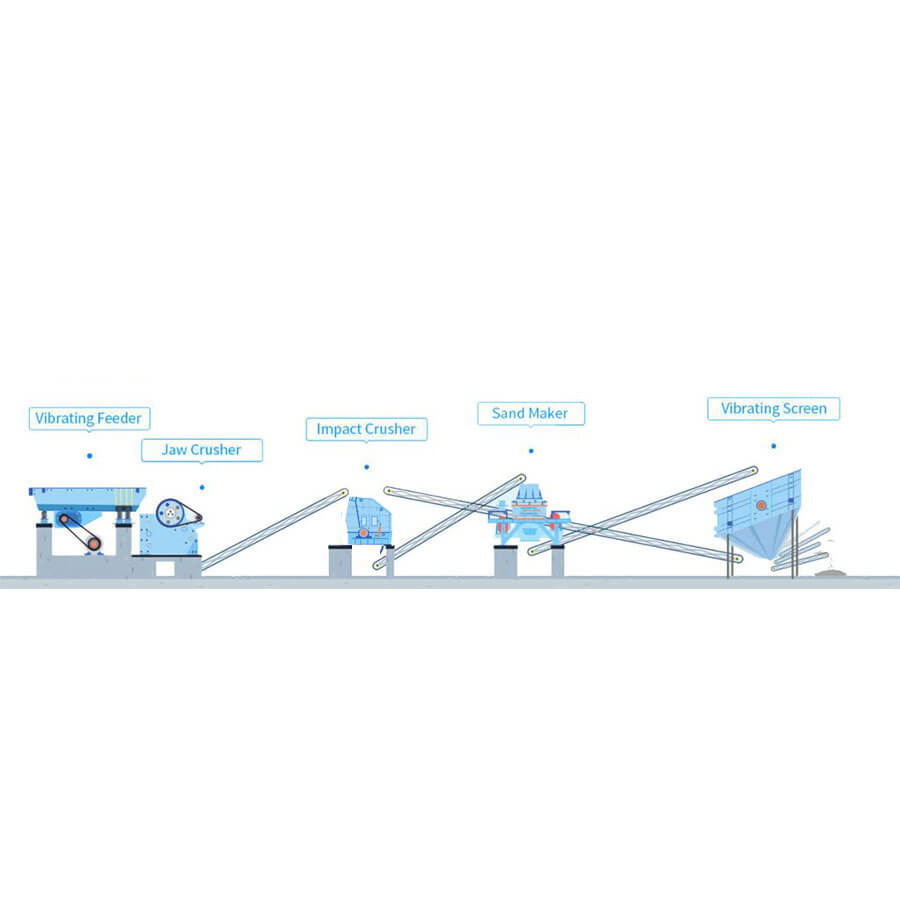

Small production line: suitable for projects with small annual output and low particle size requirements, generally equipped with jaw crusher, impact crusher, VSI impact crusher, sand washer and vibrating screen.

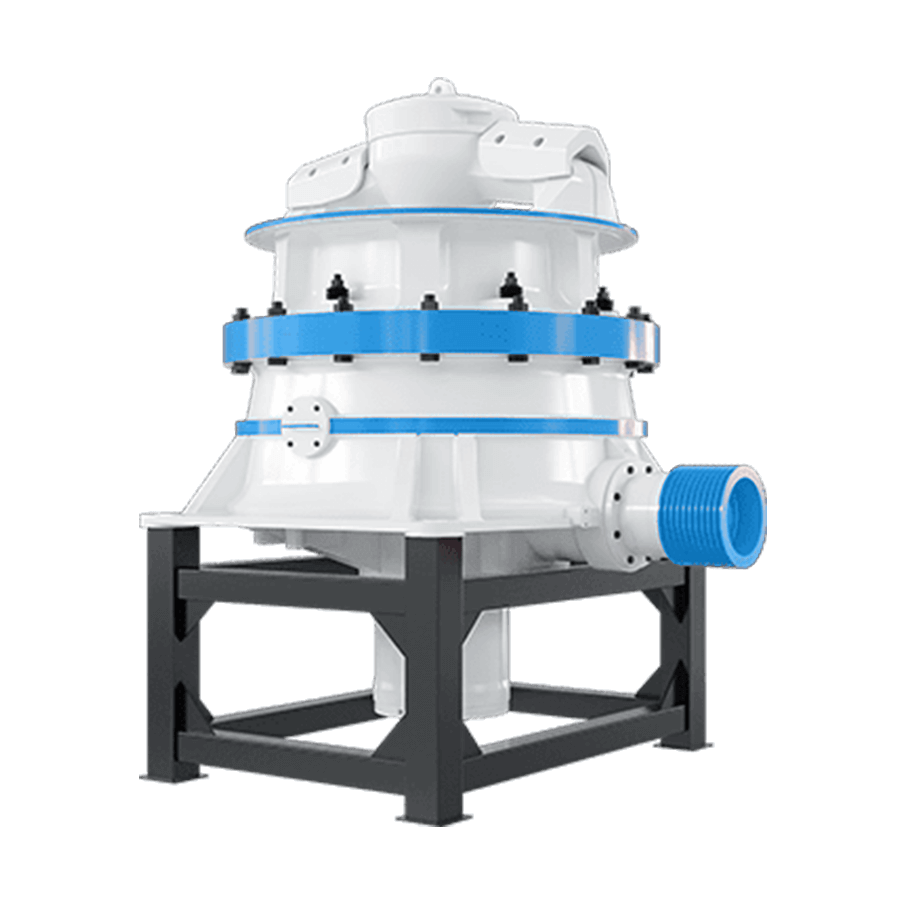

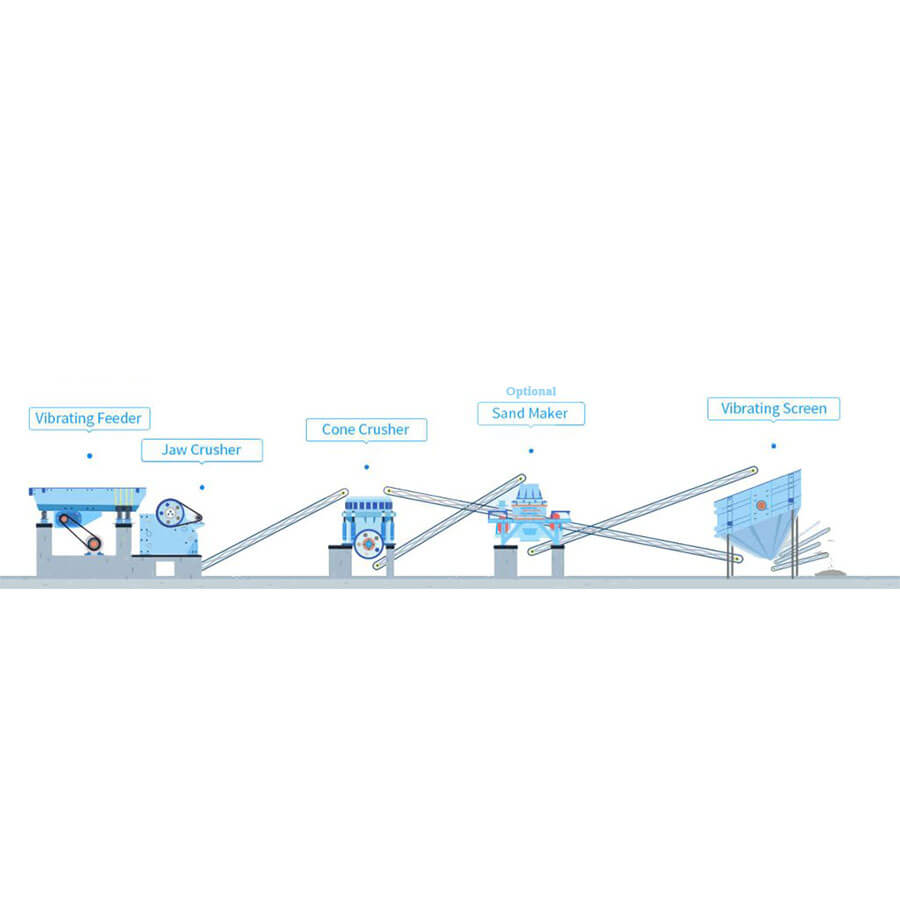

Large production line: suitable for projects with large annual output, the finished machine-made sand has perfect particle shape, usually multi-stage screening is used. Equipped with jaw crusher, cone crusher, VSI impact crusher, vibrating screen, sand washer and belt conveyor.

Small Capacity sand Crushing Plant

The small-capacity sand crushing plant equipment produced by Henan Reacore adopts the process of jaw crusher + impact crusher + impact sand making machine, with a capacity of 10-150t/h. The machine model can be replaced according to the actual needs of customers to meet different capacities.

10-20t/h sand crushing plant

The production line is configured as follows: GZD750x2500 vibrating feeder, PE400x600 jaw crusher, PF1007 impact crusher,2YK1237 vibrating screen,VSI-7611 crusher.

Capacity: 10-20 t/h

Feeding size: 1-200 mm

Voltage:220v/380v/415v/440v/480v

30-50t/h stone crushing plant

The production line is configured as follows: GZD750x2500 vibrating feeder, PE500x750 jaw crusher, PF1010 impact crusher, 3YK1548 vibrating screen, VSI-7611 crusher, XSD2610 sand washer.

Capacity: 30-50 t/h

Feeding size: 1-300 mm

Voltage:220v/380v/415v/440v/480v

50-150t/h stone crushing plant

The production line is configured as follows: GZD1000x3000 vibrating feeder, PE750x1060 jaw crusher, PF1315 impact crusher, 3YK1860 vibrating screen, VSI-1140 crusher, XSD3016 sand washer.

Capacity: 50-150 t/h

Feeding size: 1-500 mm

Voltage:220v/380v/415v/440v/480v

large Capacity sand Crushing Plant

The large capacity sand crushing plant equipment produced by Henan Reacore uses jaw crusher + impact crusher or cone crusher as the main crushing equipment, capacity 150-500t/h. The machine model can be replaced according to customer needs to increase the output.

150-200t/h sand crushing plant

The production line is configured as follows: GZD1200x5000 vibrating feeder, PE1000x1200 jaw crusher, PF1520 impact crusher or HP200 cone crusher, 3YK2470 vibrating screen, VSI-1140 crusher, XSD3620 sand washer.

Capacity: 150-200 t/h

Feeding size: 1-550 mm

Voltage:220v/380v/415v/440v/480v

200-300t/h sand crushing plant

The production line is configured as follows: GZD1500x6000 vibrating feeder, PE1400x1600 jaw crusher, PF1820 impact crusher or HP300 cone crusher, 3YK2470 vibrating screen, VSI-1140 crusher, XSD3620 sand washer.

Capacity: 200-300 t/h

Feeding size: 1-650 mm

Voltage:220v/380v/415v/440v/480v

300-500t/h sand crushing plant

The production line is configured as follows: GZD2200x8000 vibrating feeder, PE1600x2100 jaw crusher, PF2520 impact crusher, HP500 cone crusher, 4YK3070 vibrating screen, VSI-1250 crusher, XSD3816 sand washer.

Capacity: 300-500 t/h

Feeding size: 1-750 mm

Voltage:220v/380v/415v/440v/480v

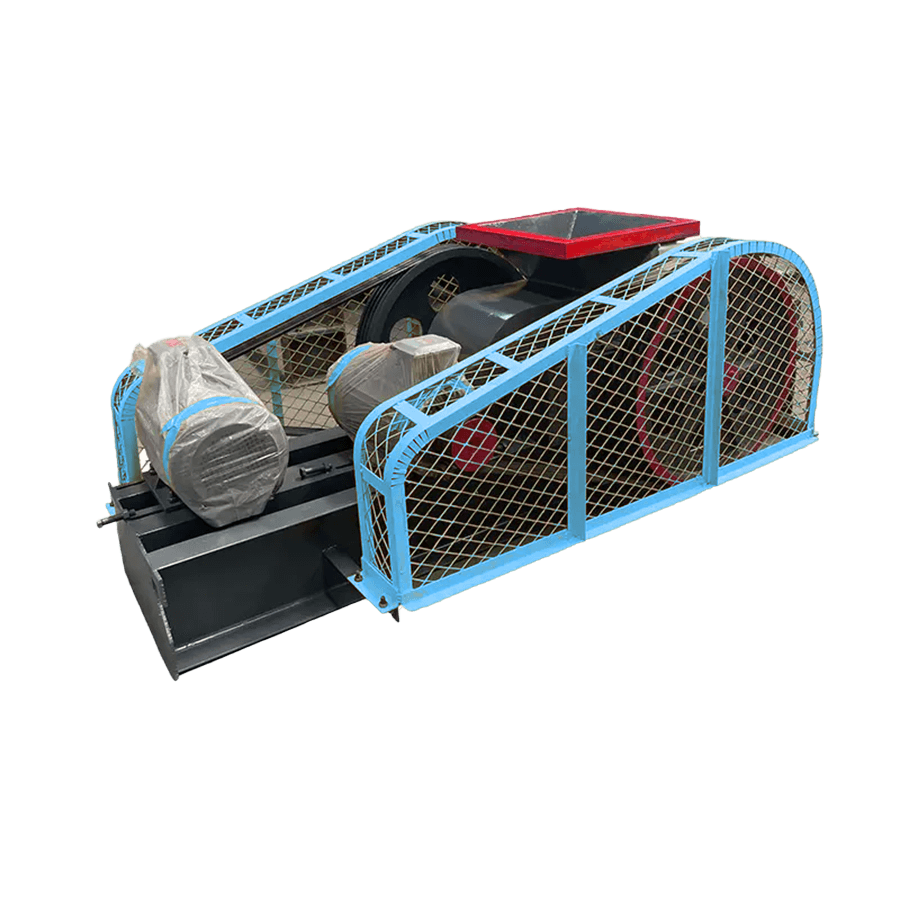

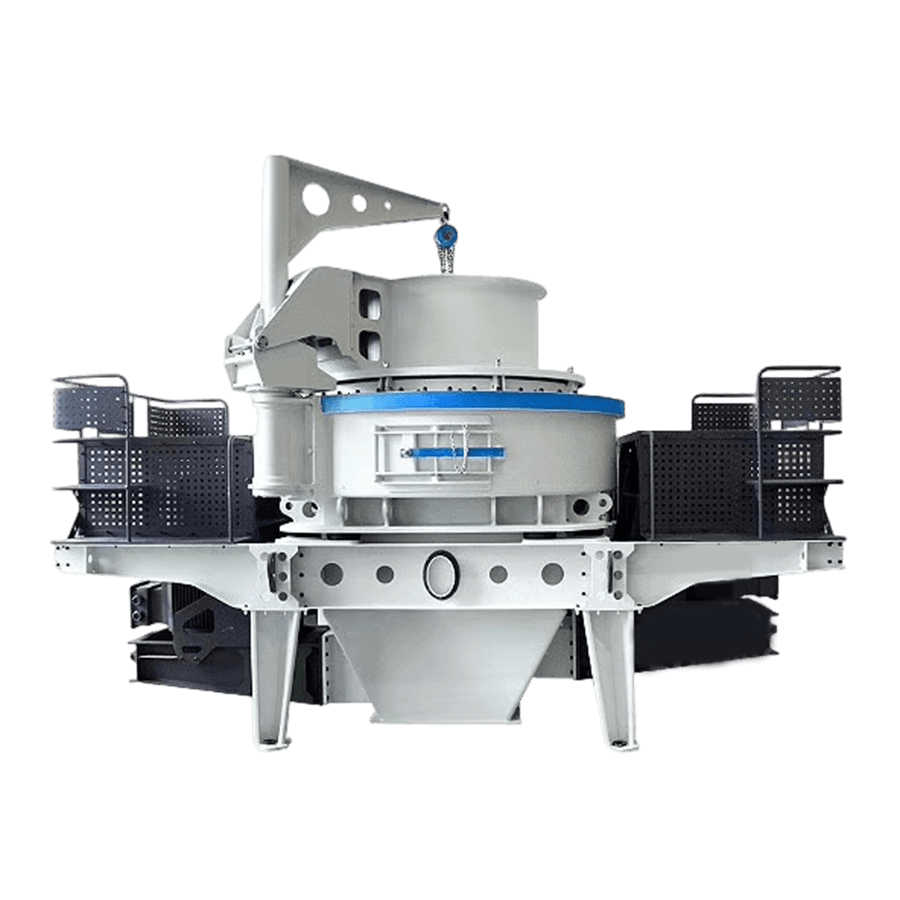

Product Structure

The sand making and crushing production line is mainly composed of feeding, crushing, sand – making, screening, washing and conveying systems. The feeding system includes vibrating feeders for uniform feeding; the crushing system is equipped with jaw crushers, cone crushers, etc. for primary and secondary crushing; the sand – making system mainly uses VSI sand – making machines to achieve fine crushing and shaping of materials; the screening system uses vibrating screens for classification; the washing system uses sand washers to remove impurities; the conveying system connects each part through belt conveyors to ensure efficient material transfer. There are also electrical control and dust removal devices for auxiliary operation.

How it works

When the sand making and crushing production line operates, the vibrating feeder evenly sends raw materials into the crusher for primary crushing to reduce the particle size of materials. The coarsely crushed materials then enter the sand – making machine for further fine crushing and shaping to make them closer to the ideal sand particle shape. Subsequently, the vibrating screen screens the materials. Qualified sand particles enter the sand washer to remove impurities such as soil and stone powder, improving the cleanliness of the finished sand. Unqualified materials are returned to the sand – making machine for re – processing. Belt conveyors run through the whole process to achieve efficient material transfer. All links work in coordination to continuously produce machine – made sand meeting the standards.

Application Areas

The sand crushing plant processes raw materials into sand and gravel aggregates of different particle sizes through a series of crushing, screening, washing and other processes, which are widely used in many industries such as construction, highways, and cement. The sand production line equipment produced by Henan Reacore can produce sand and gravel with uniform particle size and high quality, providing high-quality raw materials for various infrastructure construction.

Product Advantages

1. Efficient production: The equipment has high collaborative efficiency, which can meet the needs of large-scale production and achieve high-yield and efficient production.

2. High degree of automation: The modern sand production line is equipped with a PLC control system, with a high degree of automation in the production process, easy operation, reduced manual intervention, and improved production efficiency.

3. Uniform particle size: Through reasonable crushing and screening configuration, the particle size of the finished sand can be uniform to meet the needs of different construction projects.

4. Environmental protection and energy saving: The equipment is equipped with a dust removal system to effectively reduce dust pollution, remove impurities during the sand washing process, and improve the quality of sand and gravel. At the same time, the equipment design is energy-saving and reduces operating costs.

5. Adjustable particle size: According to demand, the crushing and screening equipment of the production line can be adjusted to flexibly control the particle size of the finished sand to meet different engineering needs.

6. Strong durability: The equipment uses highly wear-resistant materials, has strong wear resistance and long-term stable operation characteristics.

7. Multifunctional application: The sand production line is not only suitable for the production of natural sand, but also can be used for the recycling and treatment of other materials such as construction waste and ore, with strong adaptability.

8. Reduce environmental pollution: By equipping with advanced environmental protection equipment, the sand making production line can effectively reduce the impact of dust, noise and wastewater on the environment.

Product Parameters

| Capacity(t/h) | 100-200 | 200-300 | 300-500 |

| Feeder | GZD850x3000 | GZD750x2500 | GZD850x3000 |

| Primary crusher | PE600x900 | PE900x1200 | PEl200x1500 |

| Fine crusher | PF1210 | PF1315 | RS1415 |

| VSI crusher | VSI-7611 | VSI-8518 | VSI-1140 |

| Screening machine | 2YK1548 | 2YK1860 | 2YK2460 |

| The above parameters are for reference only. If you need detailed parameters, please contact us. | |||

Have you decided on the model you want to buy? If you can’t find the model you want, please contact us for consultation.

More related cases

The sand crushing plant equipment produced by Henan Reacore is your best choice whether it is used for crushing and sand making operations in mining, metallurgy, construction, highway, railway, cement industry, or secondary crushing and sand making of construction waste bricks.

Why Choose Us

We have a professional team of engineers who can design and manufacture production solutions according to your needs.

We have a professional modern production workshop, and all the equipment leaving the factory has been quality inspected.

We have many years of manufacturing experience, all equipment is independently developed and produced, the price is more favorable.

We provide a full range of technical support and can provide you with high-quality purchasing services and after-sales services.

More related products you may want to know

contact us for quote

You can tell us your needs from the following aspects:

1. What is the product name and model you want to know?

2. What type of project do you plan to buy our equipment for?

3. When will you start this project?

4. Where will you carry out your project?

If you don’t know how to choose a specific product, or you need a special project design solution, you can leave your contact information and our technical engineers will design a special solution for you.