Double Shaft Shredder Machine For Sale

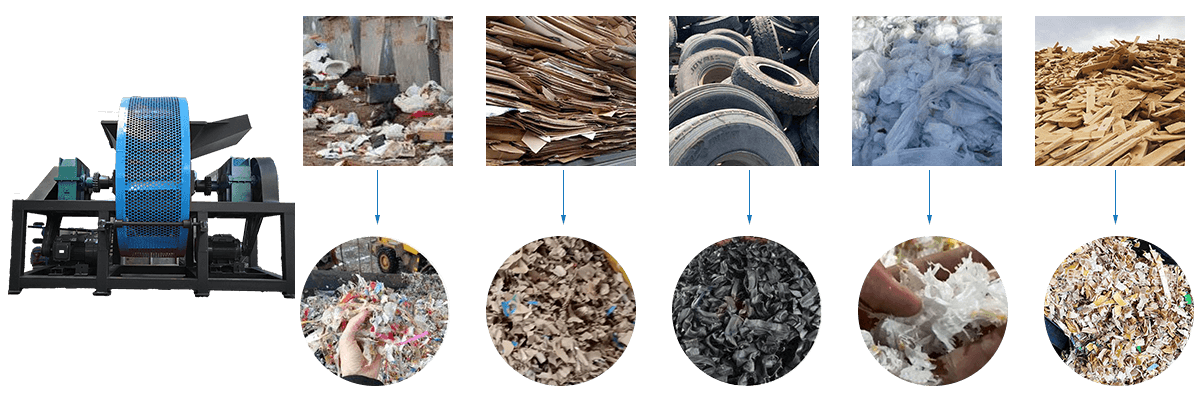

Applicable materials:

Scrap metal, plastic, frame materials, waste conveyor belts, filing cabinets, oil filters, waste televisions, refrigerators, air conditioners, washing machines, computers, mobile phones, freezers, hazardous waste, medical waste, clothing and leather scraps, large furniture, garden waste, raw household waste, construction formwork, wood boards, synthetic boards, etc.

Feeding size: <2000 mm

Power: 5-400 Kw

Capcity: 0.1-20 T/h

What is a double shaft shredder

Double-shaft shredder is a kind of equipment used to process various waste materials, usually used to crush materials with high hardness, complex shape and large volume. Compared with single-shaft shredder, double-shaft shredder has stronger tearing ability and more uniform crushing effect, and is widely used in the recycling and processing of scrap metal, waste plastic, electronic waste, industrial waste, construction waste, etc.

Types of double shaft shredder We Sale

The double-shaft shredder produced by Henan Reacore is widely used in many fields such as waste recycling and garbage disposal due to its efficient tearing ability and uniform crushing effect. It has a simple structure, strong durability and safe operation, and is one of the important equipment in the modern waste disposal industry.

The double-shaft shredders we produce are mainly divided into single-motor double-shaft shredders and dual-motor double-shaft shredders, and a variety of models are available for customers to choose according to their needs.

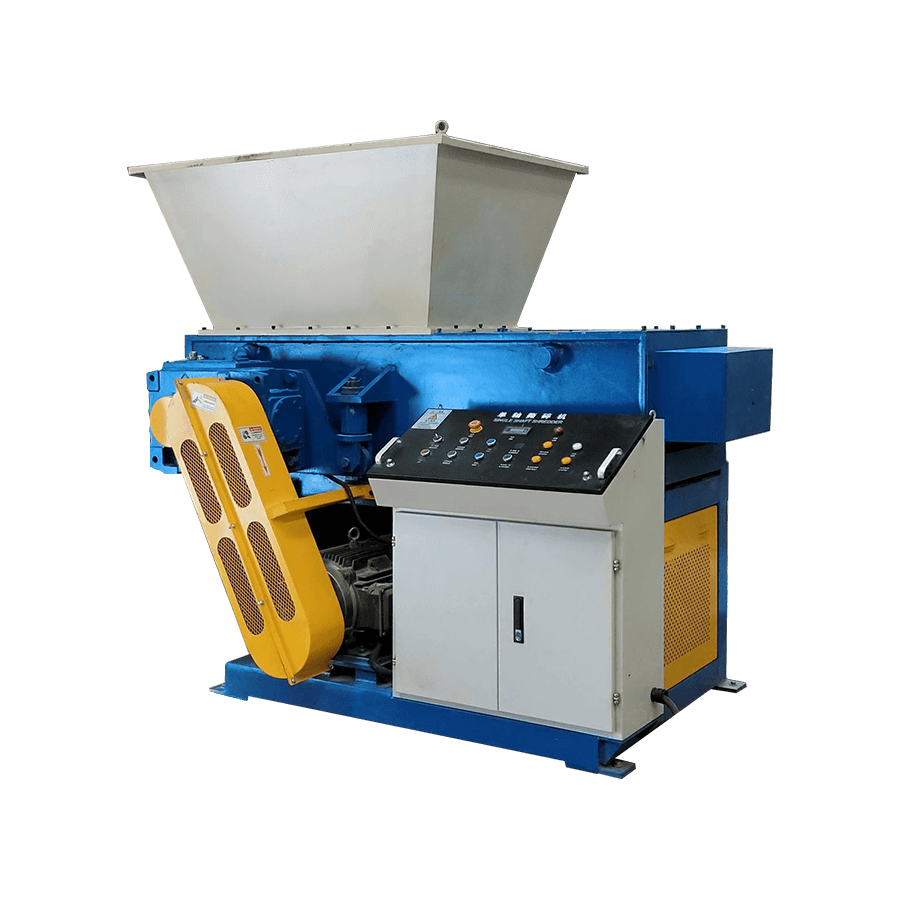

Single motor double shaft shredder

Single motor double shaft shredder (single drive) is a medium to light load shearing shredder. This product is equipped with a single motor reducer, which drives two sets of cutter shafts to run simultaneously through a gear differential. The product is compact in size, but works stably, safely and reliably. The capacity can reach 400-600 kg per hour, and the feed size is less than 500mm.

Single motor double shaft shredder

The single motor double shaft shredder produced by Henan Reacore is suitable for various small or personal projects, especially for processing kitchen waste from various restaurants or households.

Capacity: 0.1-0.6 t/h

Feeding size: <500 mm

Voltage:220v/380v/415v/440v/480v

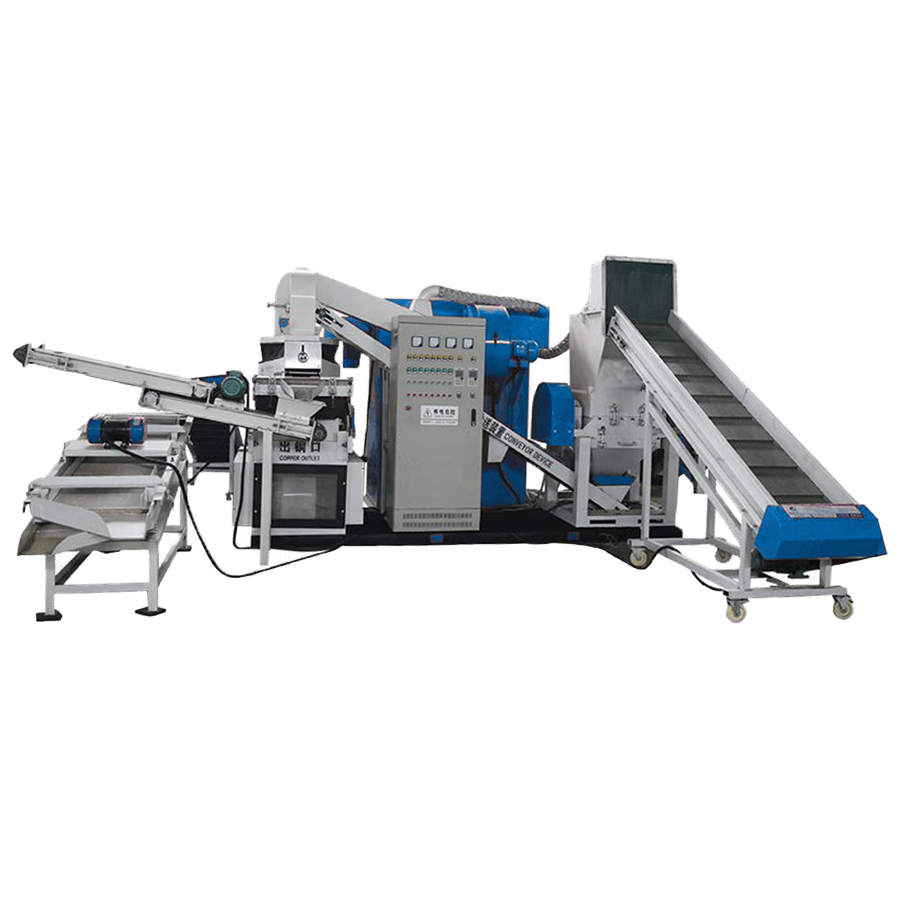

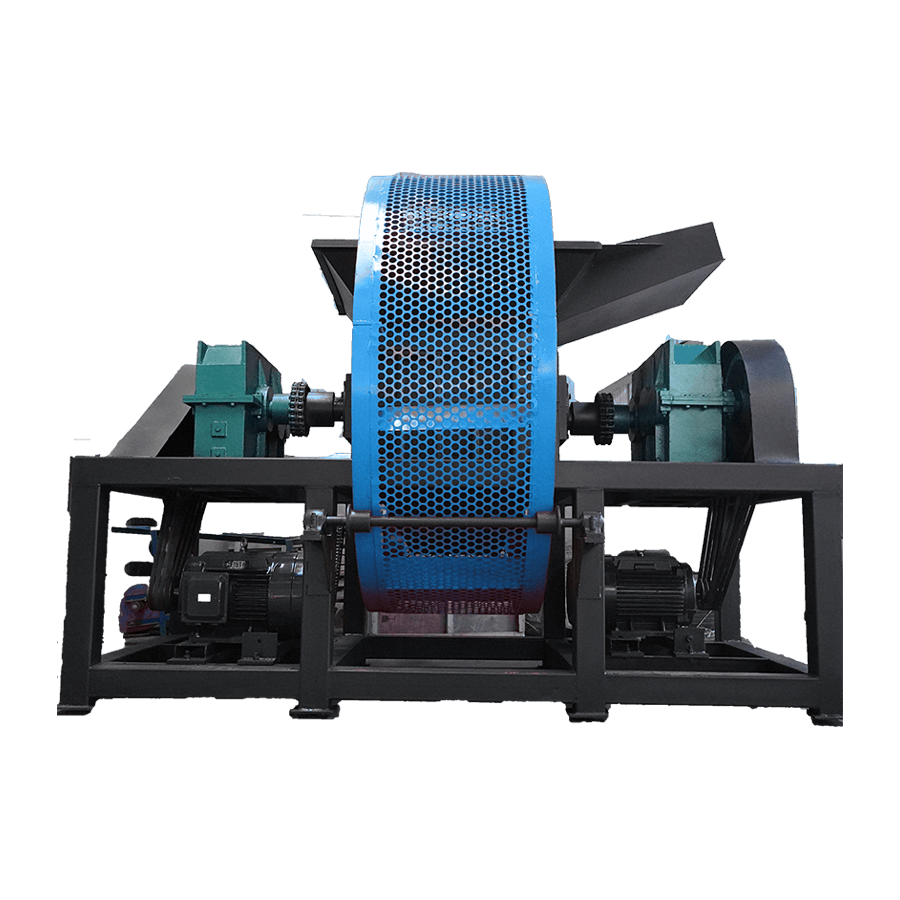

double shaft shredder

The double-shaft shredder produced by Henan Reacore can reduce the size of materials by shearing, tearing and squeezing, and is widely used to crush waste plastics, waste rubber, wood and other large-volume waste. It is suitable for crushing various waste metals, wood, plastics, tires, clothing, animal carcasses, garden waste, medical waste, domestic waste, solid waste, industrial waste and various difficult-to-handle waste.

The feed size of the machine is 100-2000mm, and the capacity can reach 0.1-20t/h. It can be modified according to customer needs. (Such as adding a screen cover, a pressing device, etc.)

double shaft shredder

The double-shaft shredder (double motor drive) produced by Henan Reacore adopts a detachable main shaft design and wear-resistant blades, which greatly improves work efficiency and service life.

Capacity: 0.1-20 t/h

Feeding size: 100-2000 mm

Voltage:220v/380v/415v/440v/480v

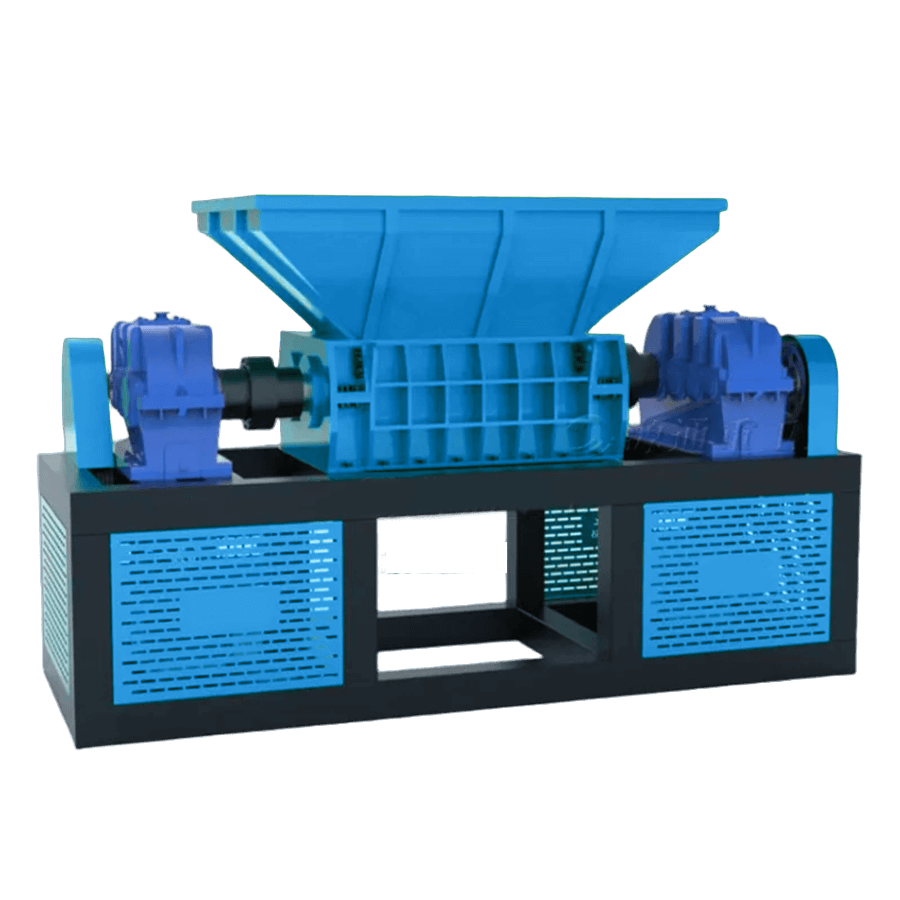

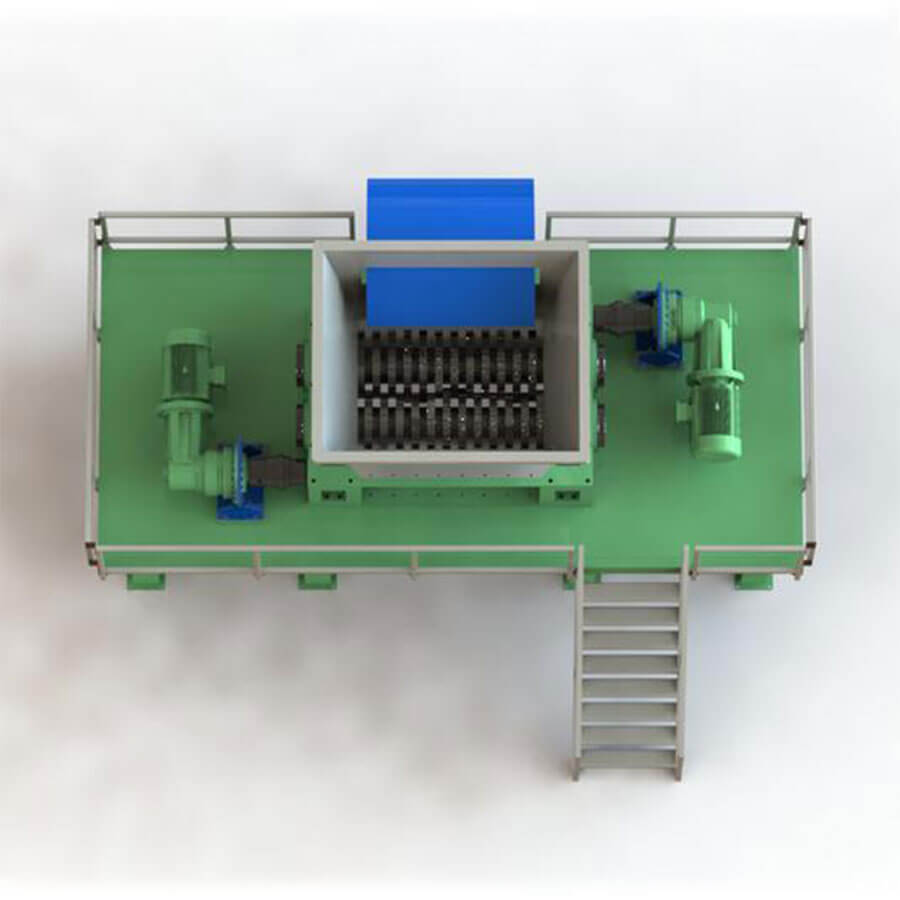

Product Structure

The main structural parts of the double-shaft shredder include the following parts:

Frame: The frame is the foundation of the entire shredder. It is usually made of strong steel and can withstand the huge forces generated during the shredding process.

Motor: The motor provides driving power. High-power motors are usually selected to ensure sufficient shredding capacity.

Blades: The blades of the double-shaft shredder consist of two horizontally mounted rotors, usually made of wear-resistant steel. Multiple blades are installed on each rotor, which cut the material by rotation.

Transmission system: The double-shaft shredder is equipped with a high-strength reducer and a transmission chain or gear to ensure that the two sets of rotors rotate synchronously.

Feed port: The material enters the shredder through the feed port. The feed port is usually designed to be wide to accommodate the input of various materials.

Discharge port: The shredded material will be discharged through the discharge port, equipped with a screen or other sorting device to control the particle size of the material.

Hydraulic system (optional): Equipped with a hydraulic system to adjust the pressure of the blade to adapt to materials of different hardness.

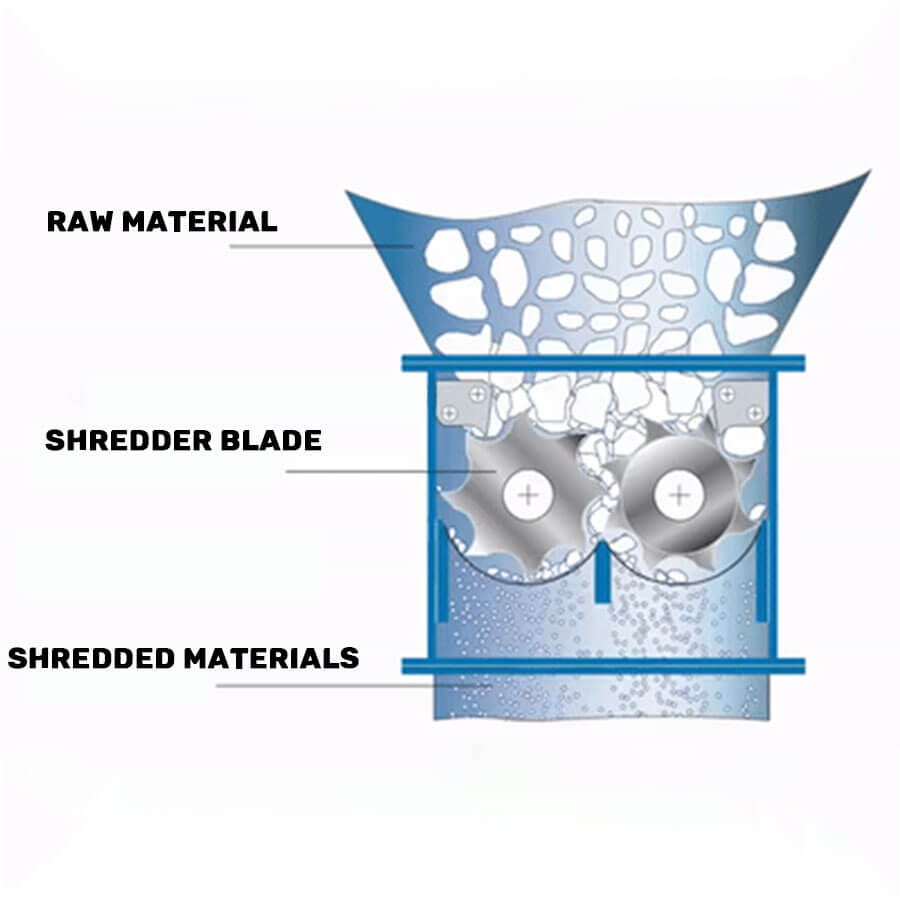

How it works

The working principle of the double-shaft shredder is based on two horizontally mounted rotors tearing and cutting the material with rotating blades.

The material enters the shredder through the feed port and comes into contact with the blades of the rotors. The two rotors of the double-shaft shredder rotate simultaneously, and the blades on the rotors continuously tear and cut the material. Due to the low rotation speed of the rotors, the material is strongly torn between the blades and gradually broken into smaller pieces. The cut material is discharged through the discharge port. The discharged material is usually passed through a screen or other sorting device to ensure that its particle size meets the requirements.

Application Areas

The double-shaft shredder produced by Henan Reacore is suitable for shredding and recycling various solid waste materials. Its efficient tearing ability and uniform crushing effect are well received by the industry. It is most commonly used for shredding various waste plastics, waste rubber, wood and other large-volume waste. It is suitable for waste recycling and garbage disposal and other fields.

Product Advantages

1. Thickened knife box design, stable quality.

2. The iron frame plate is very thick, can withstand high torque, and is very strong.

3. Imported high-strength alloy knife material, tough and wear-resistant.

4. Transmission protection structure, five-fold protection, long service life.

5. Moving knife: imported high-alloy steel, durable.

6. Fixed knife: independent disassembly and assembly structure, simple maintenance, and prevention of material entanglement.

7. Spindle: imported high-alloy steel, good mechanical strength, strong impact resistance.

8. Bearing: spherical roller bearing, 4-fold seal, effective dust and water resistance.

9. Knife box: combined assembly, modular design, each assembly can be removed for maintenance and replacement.

10. Motor: equipped with brand motor, stable operation, low failure rate.

11. Reducer: planetary reducer, high torque, strong impact resistance.

12.Electrical control: Siemens PLC control system, with automatic control, start, stop, reverse and overload functions.

Product Parameters

| Model | Spindle length (mm) | Spindle speed (rpm) | Number of blades (pcs) | Blade diameter (mm) | Blade thickness (mm) | Motor power (kw) | Dimensions(mm) | Machine weight (kg) | Capacity(t/h) |

| RC-SSD300 | 400 | 15 | 24 | 180 | 12 | 3 | 850x500x1300 | 400 | 0.3 |

| RC-SSD400 | 500 | 15 | 26 | 180 | 15 | 7.5 | 1100x550x1220 | 500 | 0.5 |

| RC-SS400 | 670 | 15 | 20 | 180 | 15 | 5.5*2 | 1565x540x1509 | 500 | 0.1-0.3 |

| RC-SS500 | 860 | 15 | 20 | 200 | 20 | 7.5*2 | 2505x1160x1800 | 1000 | 0.3-0.5 |

| RC-SS600 | 1100 | 15 | 20/30 | 220 | 30/20 | 15*2 | 2800x1200x1800 | 2200 | 0.5-1 |

| RC-SS800 | 1360 | 10-12 | 20 | 300 | 40 | 30*2 | 3200x1600x2300 | 3200 | 2 |

| RC-SS1000 | 1680 | 10-12 | 20/25 | 300 | 50/40 | 37*2 | 4000x1800x2420 | 4800 | 3-5 |

| RC-SS1200 | 1860 | 10-12 | 24/30 | 400 | 50/40 | 55*2 | 4300x2000x2520 | 6500 | 5-6 |

| RC-SS1400 | 2100 | 10-12 | 28 | 400 | 50 | 55*2 | 4900x2440x2940 | 9000 | 6-8 |

| RC-SS1600 | 2450 | 10-12 | 32 | 550 | 50 | 75*2 | 5300x2500x3000 | 11000 | 8-10 |

| RC-SS1800 | 2660 | 8-10 | 36/22 | 550 | 80/160 | 75*2/132*2 | 6100x2560x5200 | 20000 | 10-12 |

| RC-SS2000 | 2756 | 6-8 | 40 | 650 | 100 | 160*2/200*2 | 9400X2500X3000 | 25000 | 15-20 |

Have you decided on the model you want to buy? If you can’t find the model you want, please contact us for consultation.

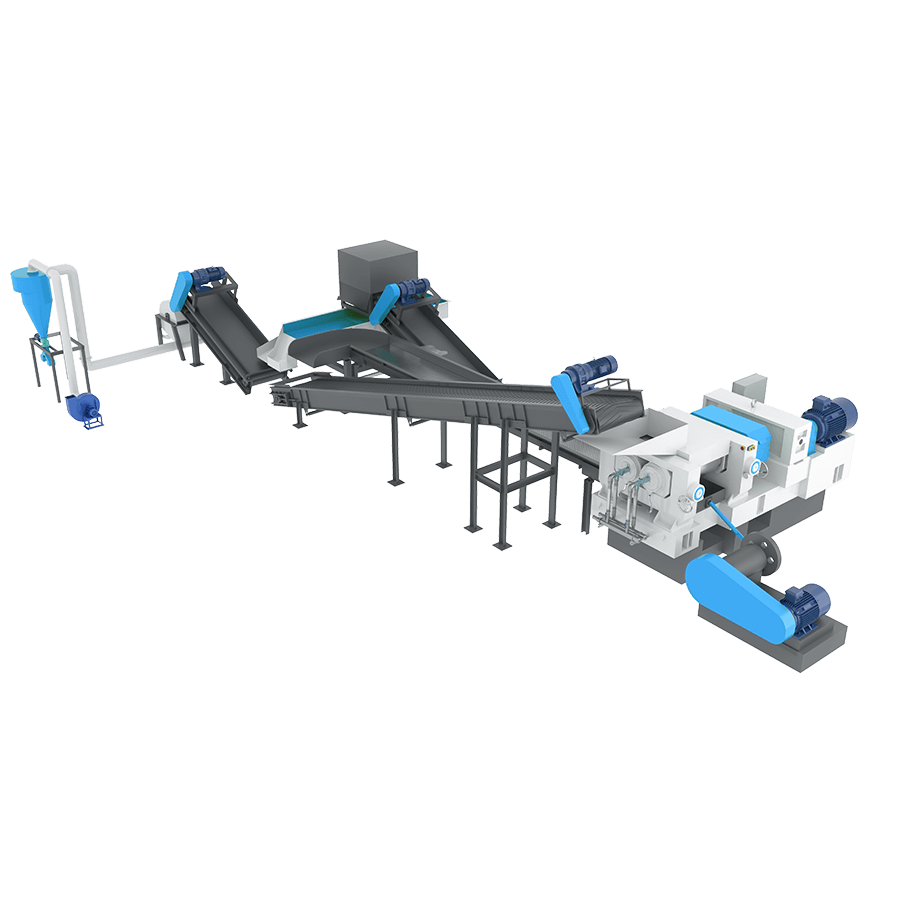

More related cases

The double-shaft shredders produced by Henan Reacore have a wide range of applications. Whether it is used to shred and recycle waste metal, waste wood, waste tires, or to shred and recycle waste industrial waste and domestic waste, Henan Reacore’s double-shaft shredders are your best choice.

Why Choose Us

We have a professional team of engineers who can design and manufacture production solutions according to your needs.

We have a professional modern production workshop, and all the equipment leaving the factory has been quality inspected.

We have many years of manufacturing experience, all equipment is independently developed and produced, the price is more favorable.

We provide a full range of technical support and can provide you with high-quality purchasing services and after-sales services.

More related products you may want to know

contact us for quote

You can tell us your needs from the following aspects:

1. What is the product name and model you want to know?

2. What type of project do you plan to buy our equipment for?

3. When will you start this project?

4. Where will you carry out your project?

If you don’t know how to choose a specific product, or you need a special project design solution, you can leave your contact information and our technical engineers will design a special solution for you.