Copper Wire Recycling Machine For Sale

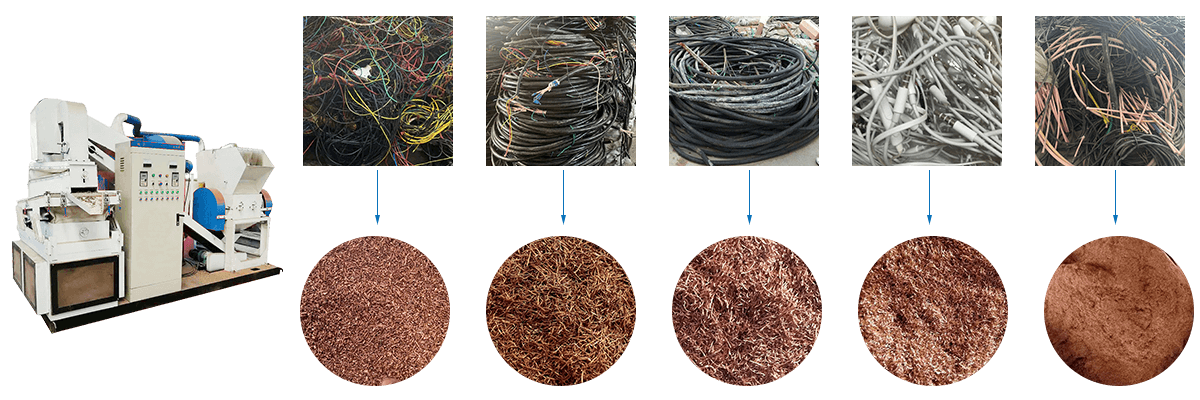

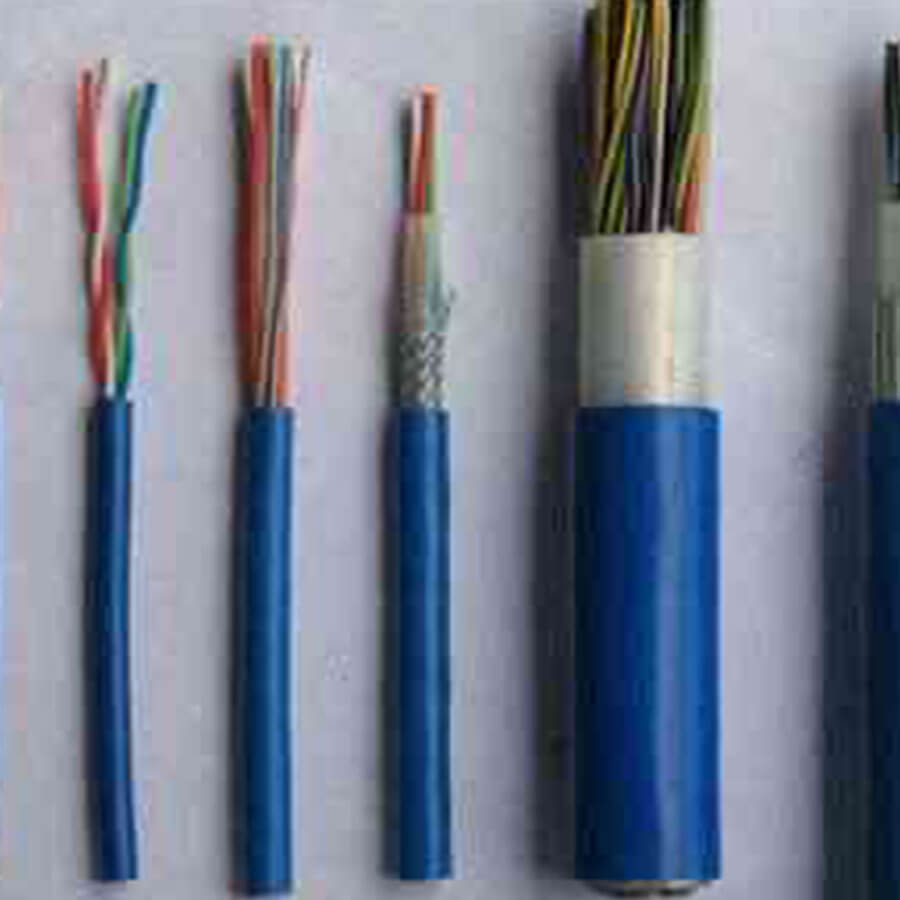

Applicable materials:

Various wires and cables, household appliance cables, communication cables, computer cables, square cables, electrical cables, headphone cables, motor cables, optical fibers, broadband cables, etc.

Separation efficiency: 99.9%

Power: 4-55 Kw

Capcity: 20-1200 kg/h

What is a copper wire recycling machine

Waste copper wire recycling plant refers to a production line that separates copper and plastic from various waste copper wires through crushing and screening processes. It can effectively separate various 1-200mm waste copper wires, wires and cables, household appliance wires, communication wires, computer wires and other waste wires that are not suitable for processing by wire stripping machines. Its production capacity can reach 20-1200 kg per hour.

The machine mainly uses physical methods to separate the copper wire from the plastic or rubber it is wrapped in, thereby extracting pure copper.

Types of copper wire recycling machine We Sale

There are many types of copper wire recycling machines produced by Henan Reacore, which are classified according to structure, processing method, processing capacity, etc. There are mainly the following types: small copper wire recycling granulator, dry copper wire recycling machines, wet copper wire recycling machines.

Regardless of the type of copper wire recycling equipment, it can effectively separate the copper or aluminum in the plastic insulation layer around the wire, and finally obtain clean copper particles, which can be used by various industries to manufacture new products.

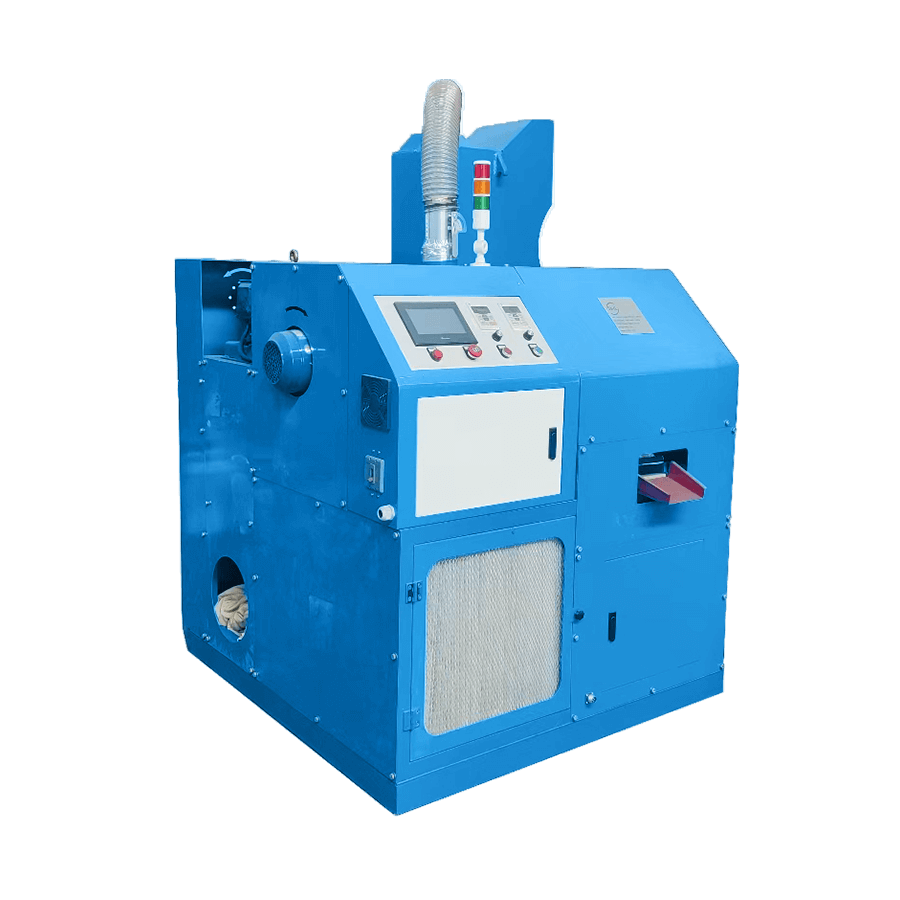

small copper wire recycling Granulator

Small copper wire recycling machine is also called small copper wire granulator. The output of this machine is usually 20-120 kg per hour. The power supply can be single-phase or three-phase, which is more suitable for small scrap recycling sites or home use. Our small copper wire granulator is equipped with universal wheels and integrated design, which occupies a smaller area.

RC-G300 Mini Copper Granulator

This mini copper wire recycling granulator is suitable for individuals or customers with small demands. It has a capacity of 20-50 kg per hour. The whole machine is equipped with universal wheels and can be moved by manual pushing.

Capacity: 20-50 kg/h

Motor power: 4 kw

Voltage:220v/380v/415v/440v/480v

RC-G500 small Copper Granulator

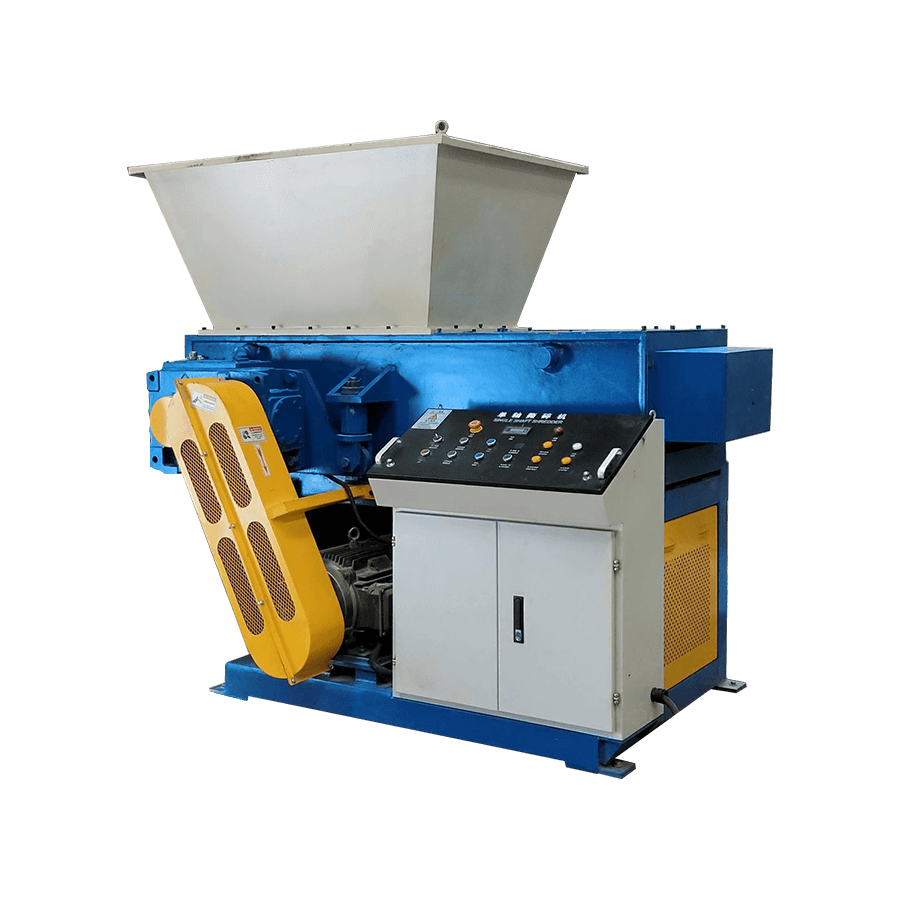

The single-shaft shredder produced by Henan Reacore can choose the appropriate knife roller and screen according to the customer’s material requirements.

Capacity: 50-150 kg/h

Feeding size: 600-1500 mm

Voltage:220v/380v/415v/440v/480v

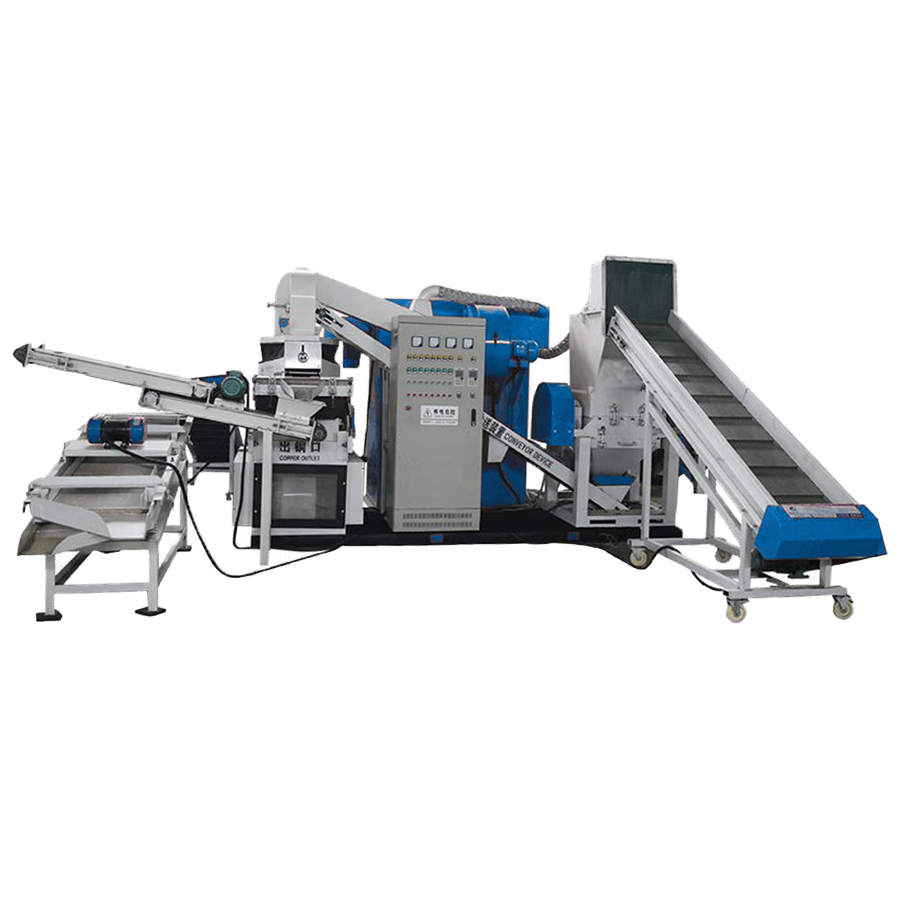

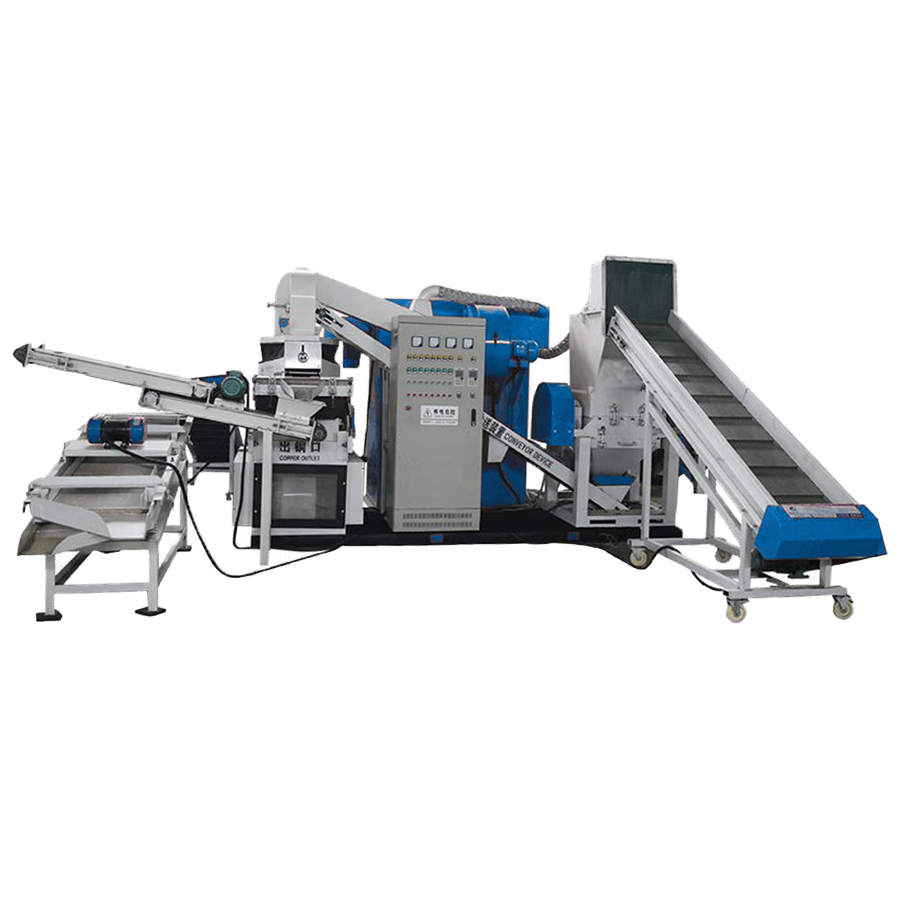

dry copper wire recycling machine

Dry copper wire recycling equipment, also known as cable recycling machine, is a device that uses dry physical sorting methods to separate copper from plastic in cable copper wires by means of airflow, vibration, magnetism, etc. The machine operates stably and is suitable for large-scale waste copper wire processing, with a capacity of 300-1200 kg/hour.

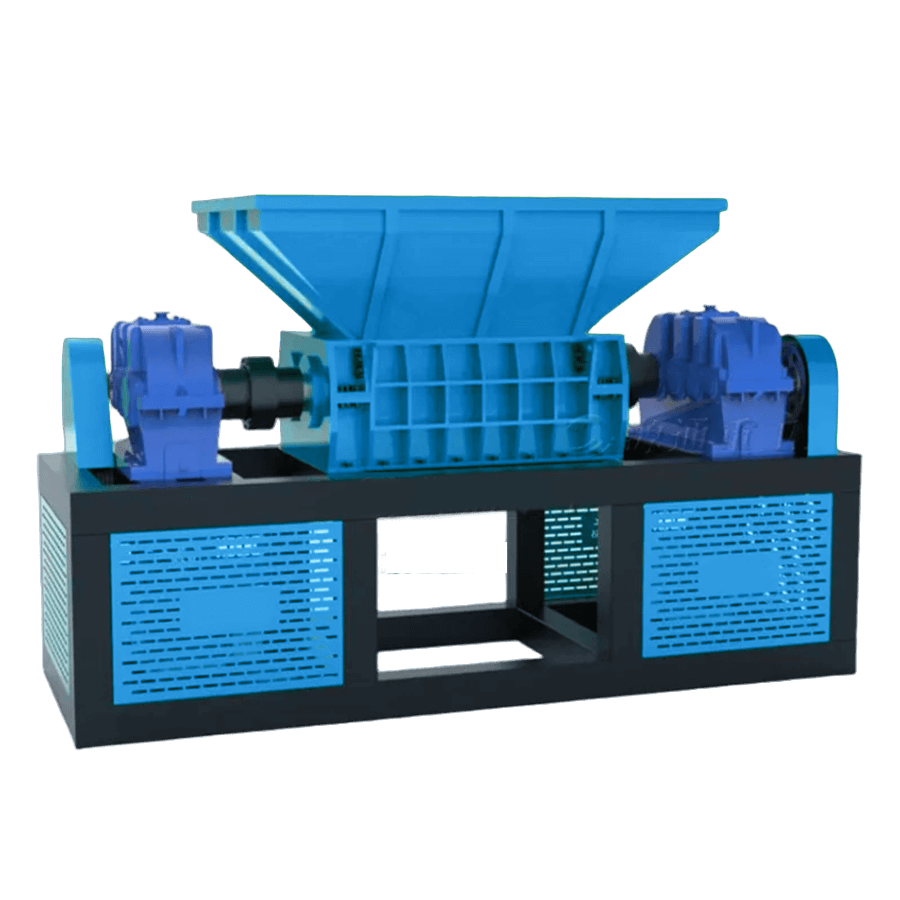

Waste cable recycling machine

The waste copper wire dry recycling machine adopts a physical sorting method with high copper recovery efficiency, which is suitable for medium and large waste copper wire recycling projects.

Capacity: 300-1200 kg/h

Motor power: 37-45 kw

Voltage:220v/380v/415v/440v/480v

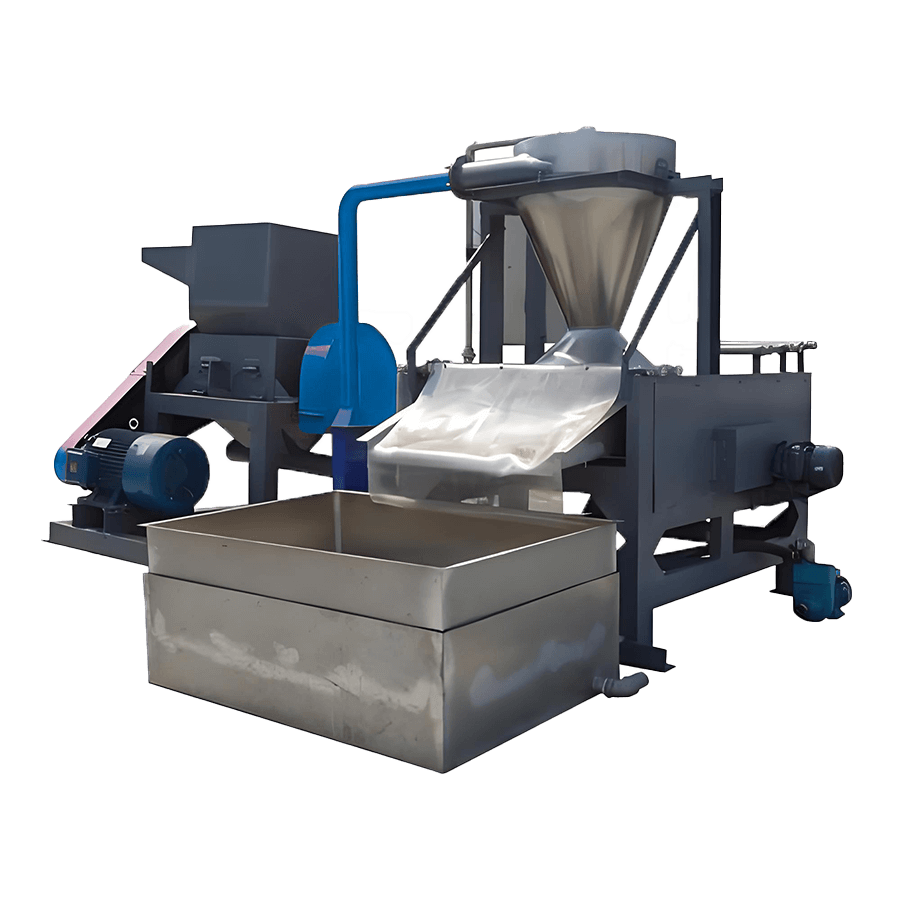

wet copper wire recycling machine

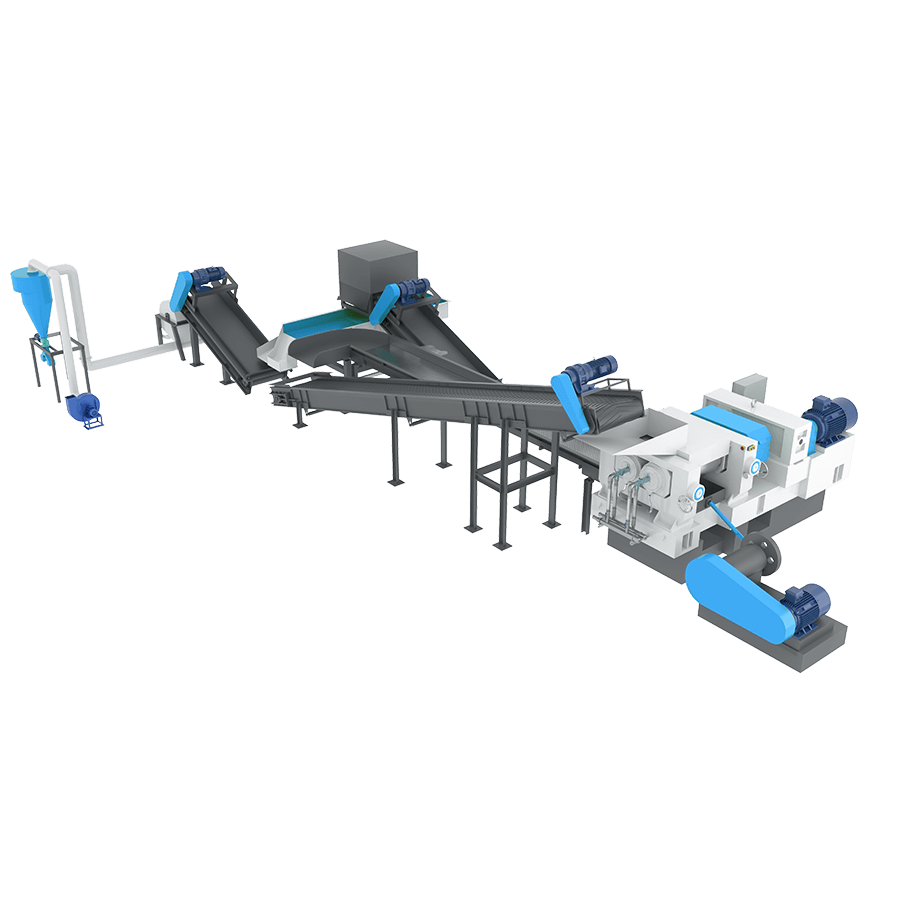

The wet copper wire recycling machines produced by Henan Reacore is an efficient and environmentally friendly waste cable recycling equipment that can separate the copper wire in the waste cable from the outer materials such as plastic and rubber through water flow sorting technology to achieve a high recovery rate.

Compared with the dry recycling method, the wet copper wire recycling line reduces pollution during the processing process and has a higher recycling efficiency.

wet cable recycling machine

The wet copper wire recycling machines adopts a circulating water system, which has little environmental pollution and a copper wire recycling efficiency of up to 99.99%, making it particularly suitable for high-recycling projects.

Capacity: 150-1200 kg/h

Motor power: 11-55 kw

Voltage:220v/380v/415v/440v/480v

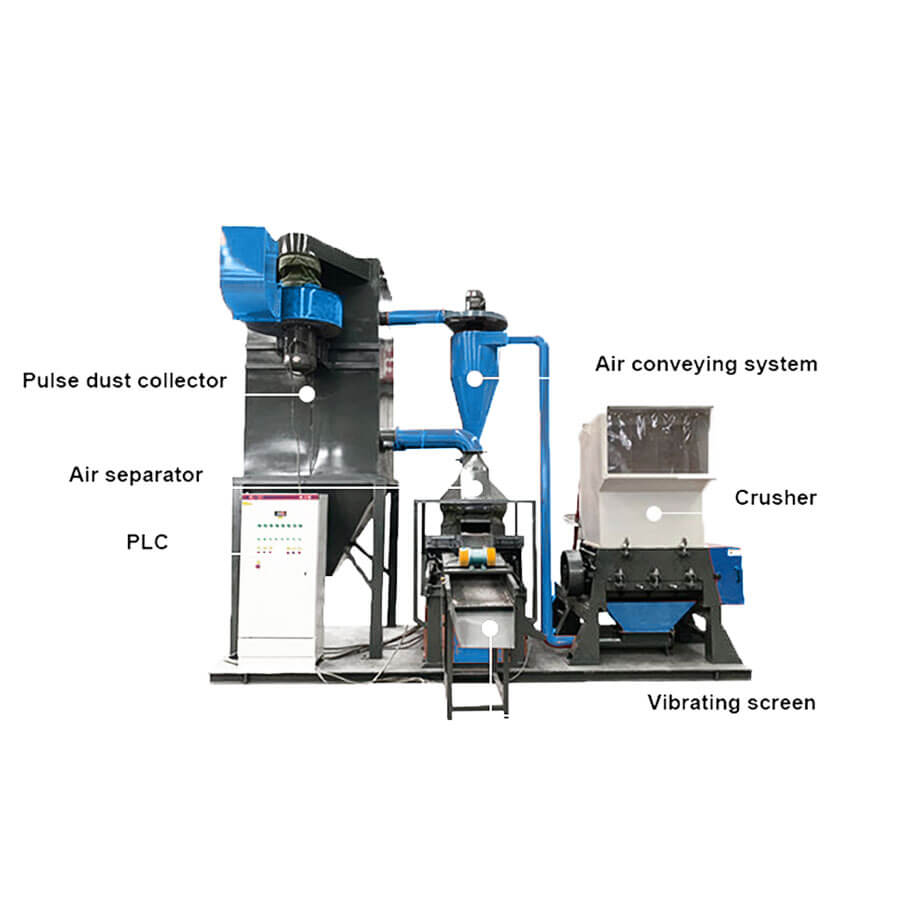

Product Structure

Waste copper wire recycling machines usually consist of the following main components.

Feeding device: The feeding device is used to feed the waste copper wire into the recycling crusher, usually with an automatic feeding device or a manual feeding system.

Crusher: The function of the crusher is to break the waste copper wire into small sections for subsequent processing. This part cuts the copper wire through a cutter and a motor drive. (A shredder can be added before the crusher to increase production capacity)

Sorting system: This system mainly uses air sorting, vibration screening, etc. to separate copper and plastic (or other materials) by using density differences, conductivity differences, etc.

Separation device: This includes a magnetic separator and an air separator, which are used to separate copper and plastic. The magnetic separator absorbs the metal components in the copper wire through a strong magnetic field, while the air separator uses airflow to separate light materials from heavy copper.

Output system: After sorting, the copper material and plastic or rubber waste will be sent out separately. The copper recovered from the copper wire can be reused, and the plastic can be processed again.

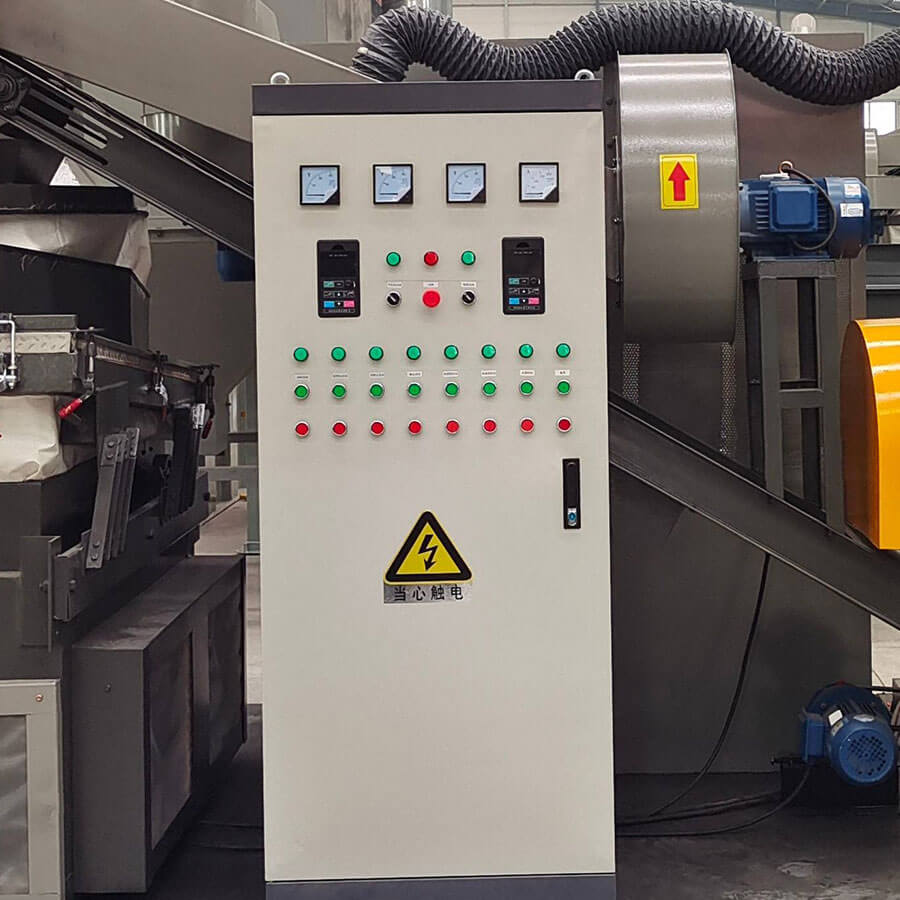

Control system: The control system includes electrical control box, PLC system, touch screen, sensor, etc., which are used to monitor the working status of the equipment in real time and perform automatic control.

How it works

The working principle of the waste copper wire recycling line mainly relies on physical sorting.

Feeding: The waste copper wire enters the recycling machine through the feeding device, and the equipment automatically or manually feeds the copper wire into the crusher for preliminary cutting.

Cutting: It is cut into smaller segments for subsequent separation and cleaning. During the cutting process, the plastic shell of the copper wire gradually separates from the copper core.

Sorting: The cut copper wire passes through the sorting system, and the copper material and the plastic shell are separated by wind, vibration, magnetism and other methods.

Collection: The separated copper material will be collected by the system’s conveying device, and other waste materials (such as plastic or rubber) will also be sent out, usually as garbage or secondary recycling materials.

Output: The copper material is further cleaned by equipment such as vibrating screens and wind screens, and pure copper metal is finally obtained, while the waste plastic shell can be sent to other recycling systems for processing.

Application Areas

Waste copper wire recycling plant is an important equipment for processing waste copper wire and waste cable. It can efficiently recycle copper metal and effectively separate waste materials. It can ensure high-purity copper recovery through physical sorting methods. It has the advantages of high efficiency, environmental protection and energy saving. It is widely used in the fields of waste wire and cable recycling, electronic waste treatment, industrial waste recycling, etc.

Product Advantages

1. Efficient sorting, the waste copper wire recycling machines can efficiently separate copper and plastic, making the copper recovery rate as high as 99.7%. Its physical sorting method ensures the purity of copper.

2. The use of physical sorting and low-energy operation methods reduces the emission of harmful substances. Dry recycling is particularly environmentally friendly and does not produce wastewater and harmful gases.

3. Low energy consumption, the design is more energy-saving, especially in large-scale processing, with lower energy consumption and reduced operating costs.

4. High degree of automation, equipped with an automated control system, can achieve full-process automated operation, reduce labor costs, and improve work efficiency.

5. Strong processing capacity, able to quickly process a large number of waste copper wires, and adapt to recycling needs of various sizes.

Product Parameters

| Model | Main motor power (kw) | Capacity(kg/h) | Weight(kg) | Dimensions (mm) |

| RC-G300 | 4 | 20-50 | 225 | 840x550x1520 |

| RC-G500 | 12.19 | 80-120 | 1300 | 1380x1300x2000 |

| RC-G600 | 37 | 300-400 | 3200 | 3900x2000x2250 |

| RC-G800 | 45 | 700-1200 | 5800 | 7200x7500x2200 |

| RC-S400 | 11 | 150-200 | 1500 | 2700x1800x2000 |

| RC-S600 | 30 | 300-500 | 3500 | 4000x2000x2400 |

| RC-S800 | 45 | 700-900 | 5000 | 8000x2200x2500 |

| RC-S1000 | 55 | 1000-1200 | 6000 | 9000x2000x2500 |

Have you decided on the model you want to buy? If you can’t find the model you want, please contact us for consultation.

More related cases

The copper wire recycling machines produced by Henan Reacore has a wide range of applications and high copper wire separation efficiency. It is suitable for the recycling production lines of copper and plastic of various waste copper wires, waste electric wires, and waste cables. No matter what type of copper wire you need to recycle, Henan Reacore’s copper wire recycling equipment is your best choice.

Why Choose Us

We have a professional team of engineers who can design and manufacture production solutions according to your needs.

We have a professional modern production workshop, and all the equipment leaving the factory has been quality inspected.

We have many years of manufacturing experience, all equipment is independently developed and produced, the price is more favorable.

We provide a full range of technical support and can provide you with high-quality purchasing services and after-sales services.

More related products you may want to know

contact us for quote

You can tell us your needs from the following aspects:

1. What is the product name and model you want to know?

2. What type of project do you plan to buy our equipment for?

3. When will you start this project?

4. Where will you carry out your project?

If you don’t know how to choose a specific product, or you need a special project design solution, you can leave your contact information and our technical engineers will design a special solution for you.