Auxiliary Machine For Sale

Application Areas:

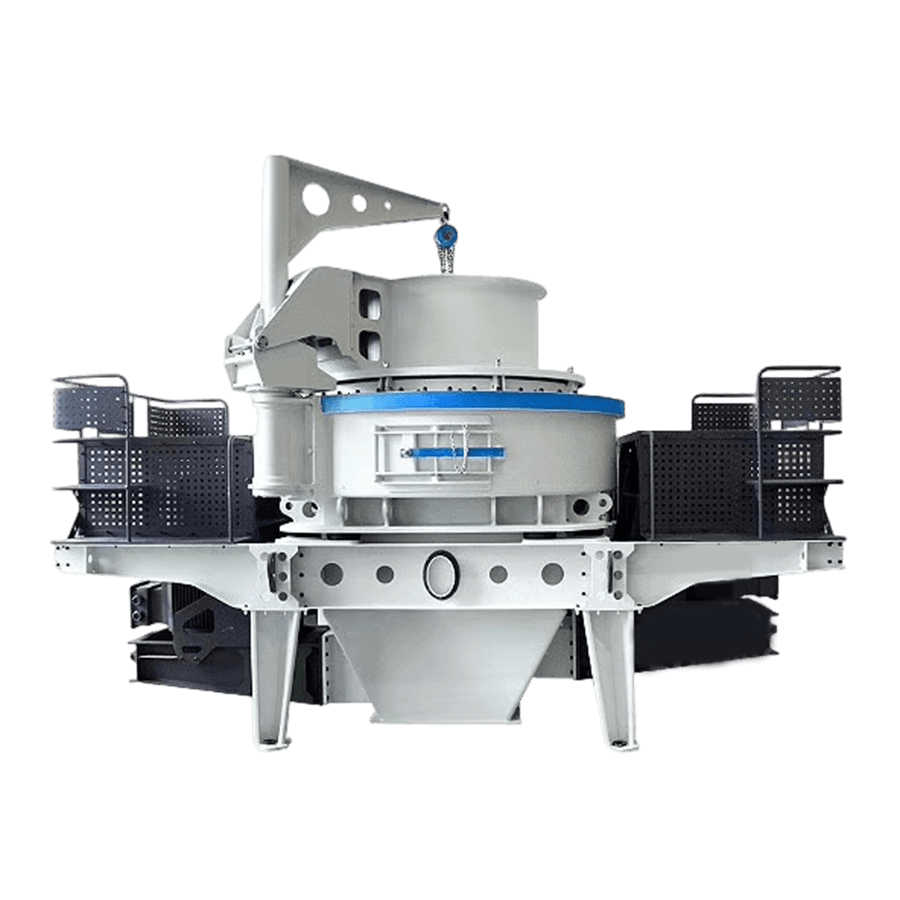

Auxiliary machine refer to the equipment other than the main machine in the mining crushing production line or environmental recycling production line. These equipment provide effective protection for the production line.

Feeding size: customize

Power: customize

Capcity: customize

What is a auxiliary machine

The auxiliary equipment produced by Henan Reacore refers to the related equipment that provides feeding, screening, conveying and other functions for the entire production line in various crushing production lines and environmental recycling production lines.

Although the auxiliary machine is an inconspicuous equipment in the production line, it provides a strong guarantee for the entire production line. All the auxiliary equipment we produce is made of sturdy and durable materials and advanced technology, with excellent quality.

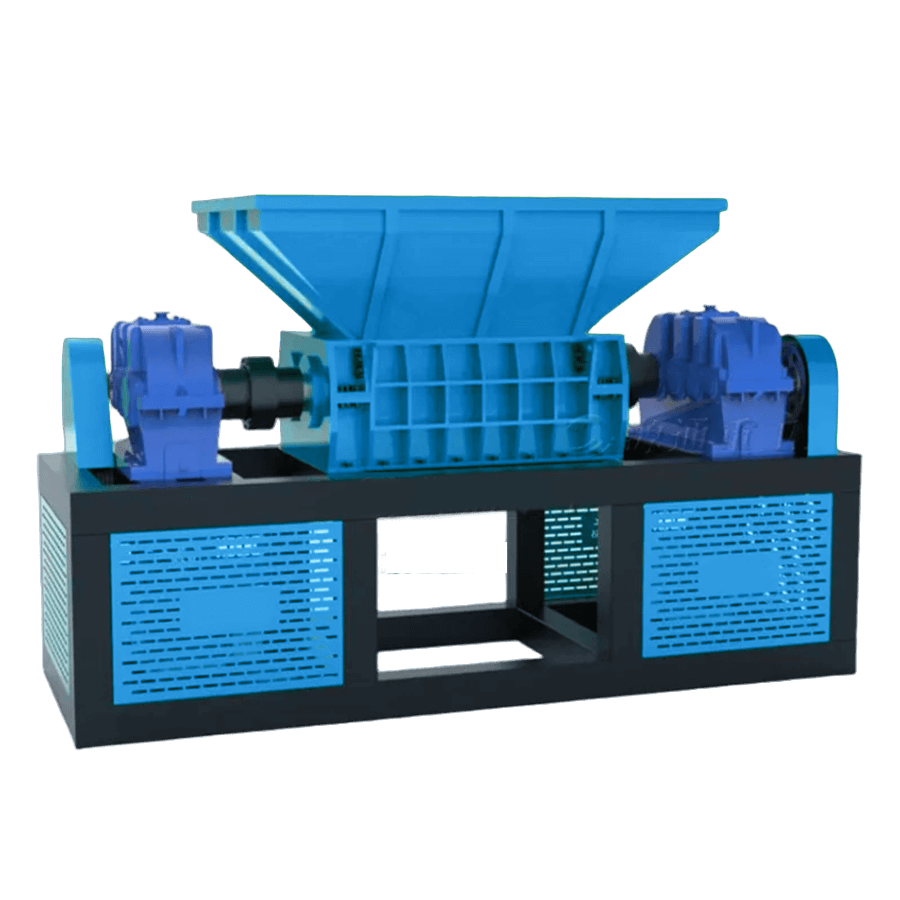

Types of auxiliary machine We Sale

As a professional manufacturer of mining crushing equipment and environmental recycling equipment, we mainly produce auxiliary equipment: vibrating feeder, electromagnetic vibrating feeder, circular vibrating screen, linear vibrating screen, belt conveyor, screw conveyor, fiber separator, bag dust collector, etc.

Feeding equipment

Feeding equipment is a device used to transport materials (such as raw materials, particles, powders, etc.) to the next processing link in a quantitative or unquantified manner during the production process. Feeding equipment is widely used in mining, chemical, metallurgy, building materials, grain processing and other industries, especially in the process of crushing, grinding, mixing, screening, etc. It plays a vital role.

The feeding equipment produced by Henan Reacore is mainly divided into: vibrating feeder, electromagnetic vibrating feeder.

Vibrating feeder

The vibrating feeder is mainly used to transport raw materials to the crusher. The vibration frequency and amplitude can be adjusted. It has stable feeding capacity and strong adaptability.

Capacity: 50-850 t/h

Feeding size: 300-950 mm

Voltage:220v/380v/415v/440v/480v

Electromagnetic vibrating feeder

Electromagnetic vibrating feeder is a small feeding equipment, which is often used to evenly convey various powdered or granular materials. It has the advantages of small size and light weight.

Capacity: 5-300 t/h

Feeding size: 50-500 mm

Voltage:220v/380v/415v/440v/480v

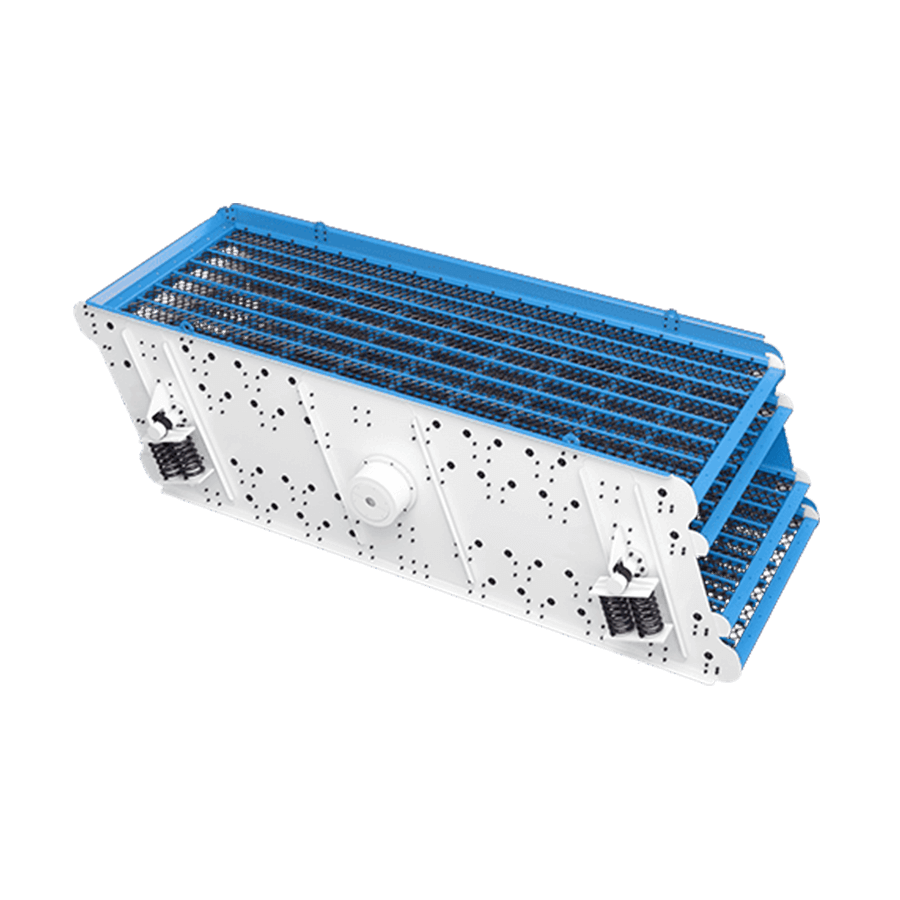

Screening equipment

Screening equipment is a kind of mechanical equipment widely used in mining, building materials, chemical industry, metallurgy and other industries to separate materials according to particle size. Screening equipment has many types according to the structure, working principle and applicable field of the screen.

The screening equipment produced by Henan Reacore is mainly divided into circular vibrating screen for mining and linear vibrating screen for environmental protection recycling production line.

vibrating screen

The mining vibrating screen is composed of a screen frame, a screen mesh, a vibrator, etc. It is often used for grading and screening of minerals, and is especially suitable for continuous work during mass production.

Capacity: 10-800 t/h

Sieve size: 3-80 mm

Voltage:220v/380v/415v/440v/480v

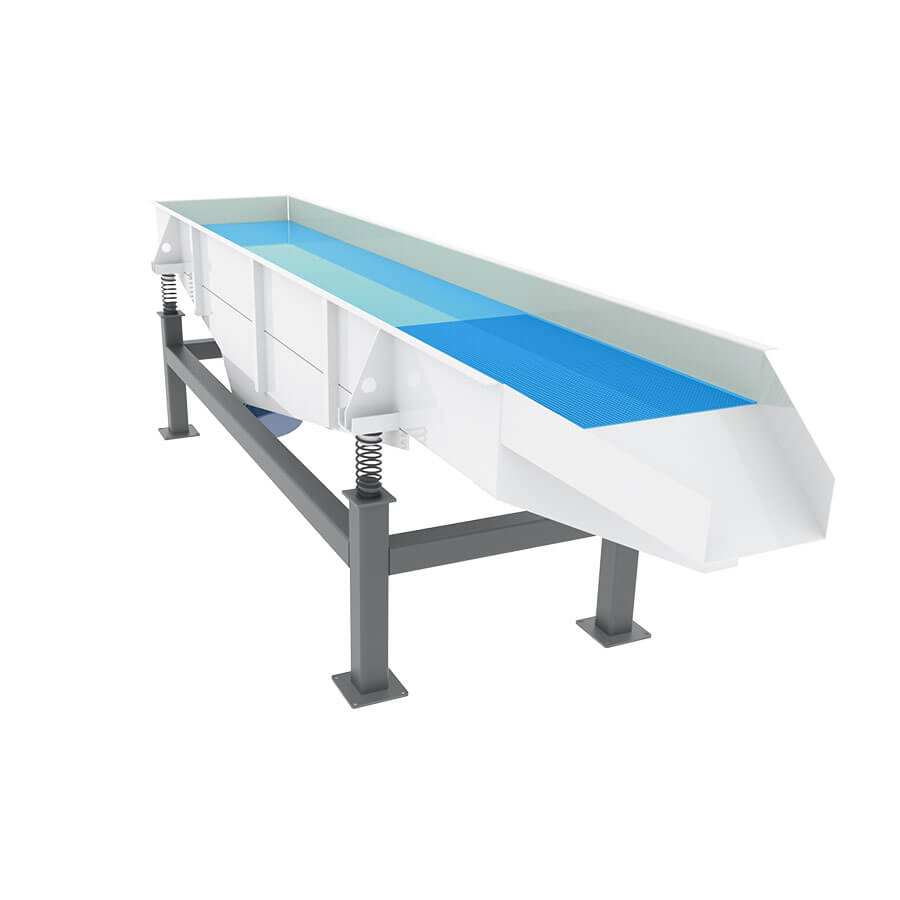

Linear vibrating screen

The linear vibrating screen uses vibration motor excitation as the vibration power source. It can be used for screening and grading powdery and granular materials and is widely used in industries such as plastics, rubber, and abrasives.

Capacity: 0.12-20 t/h

Mesh size: 2-200 mesh

Voltage:220v/380v/415v/440v/480v

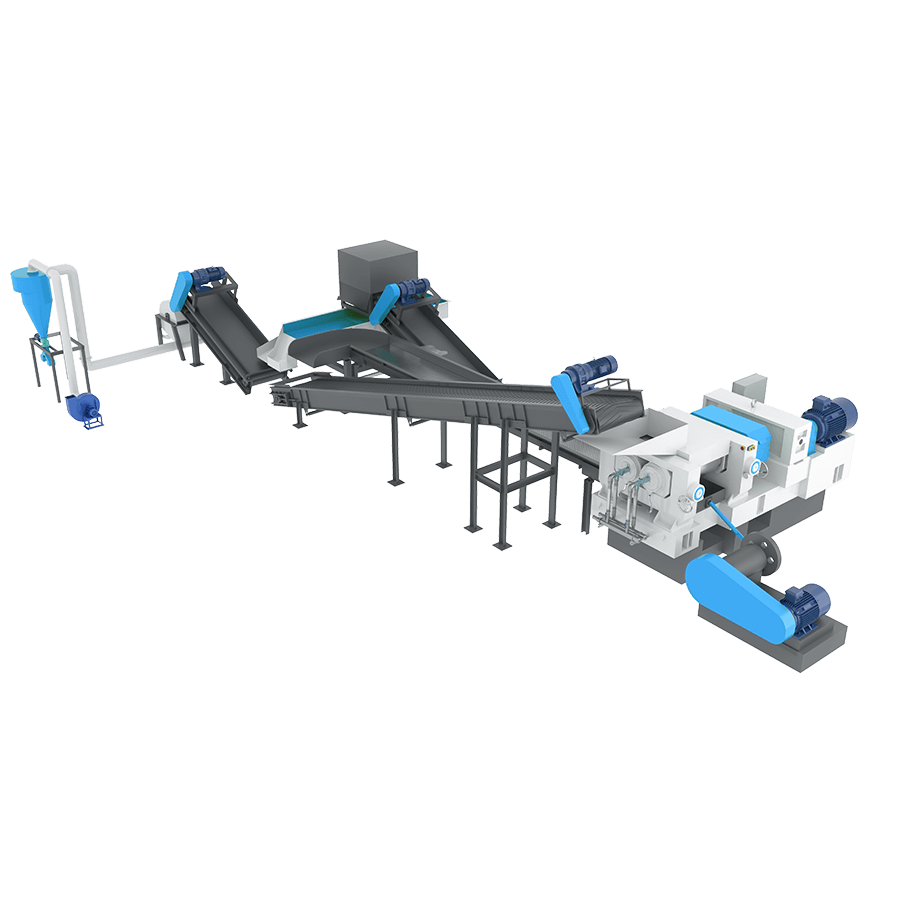

Conveying equipment

Conveying equipment is a mechanical device used to transport materials and products from one location to another, and is widely used in various production lines. Different types of conveying equipment have different working principles and applicable scenarios. It is very important to choose the appropriate conveying equipment according to factors such as the type of material, distance, speed, etc.

The conveying equipment produced by Henan Reacore is mainly divided into belt conveyors and screw conveyors.

Belt conveyor

Belt conveyor is one of the most common conveying equipment and is widely used in mining, metallurgy, coal and other industries. It has the characteristics of high conveying efficiency and large conveying capacity.

Conveying Capacity: 40-1280 t/h

Belt width: 400-1200 mm

Voltage:220v/380v/415v/440v/480v

Screw Conveyor

Screw conveyor is a machine that uses a motor to drive the screw to rotate and push materials to achieve the purpose of conveying. It can convey horizontally, inclined or vertically. It is suitable for conveying various powdery or granular materials.

Capacity: 8-95 t/h

Feeding size: 1-250 mm

Voltage:220v/380v/415v/440v/480v

Dust removal equipment

With the acceleration of industrialization, the dust generated by various production processes has a great impact on the environment and human health. Therefore, dust removal equipment plays an important role in modern industry. Common dust removal equipment includes bag dust collectors, electrostatic dust collectors, wet dust collectors, cyclone dust collectors, etc.

The dust removal equipment produced by Henan Reacore is mainly divided into bag dust collectors and fiber separators for sorting fibers.

Bag dust collector

The bag dust collector is a dry dust filtering device with a simple structure and high dust removal efficiency. It is suitable for dust removal operations in various production lines.

Filtration area: 18-90 ㎡

Power: 2.2-15 kw

Voltage:220v/380v/415v/440v/480v

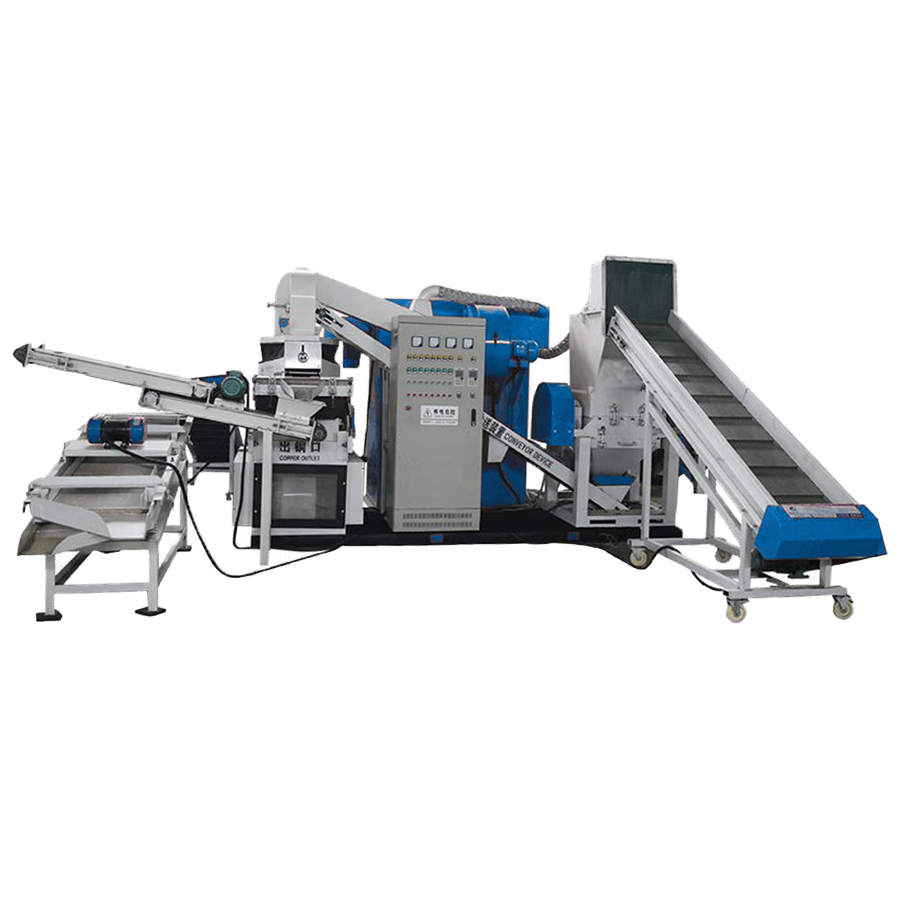

Fiber separator

The fiber separator is an air sorting machine that separates fine fluff fibers mixed in rubber powder. Its purpose is to improve the purity of rubber powder and the quality of recycled rubber products. It is also used in tire particle production lines and tire rubber powder production lines.

Capacity: 0.5-10 t/h

Power: 11 kw

Voltage:220v/380v/415v/440v/480v

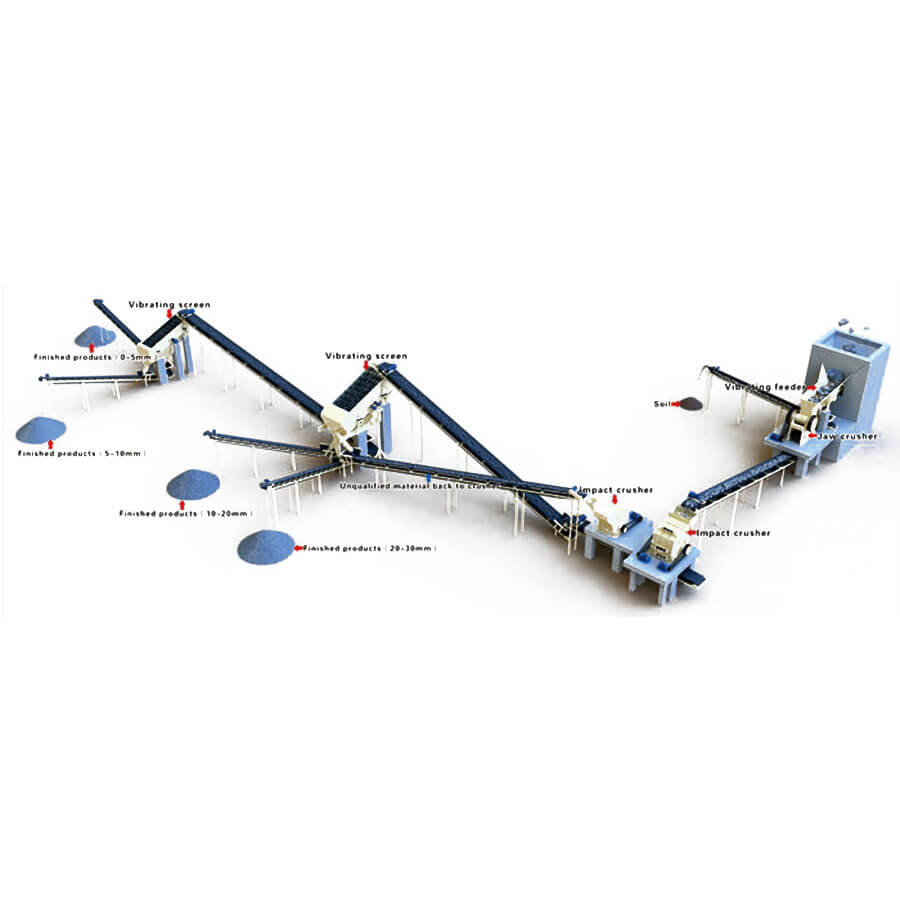

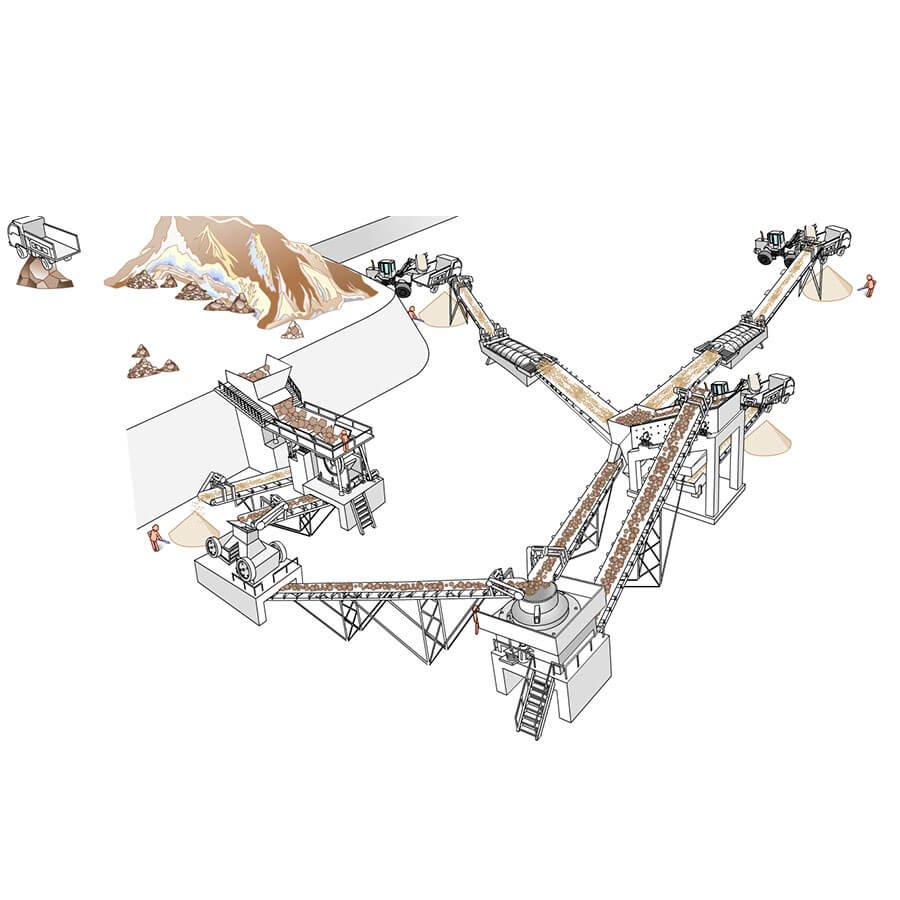

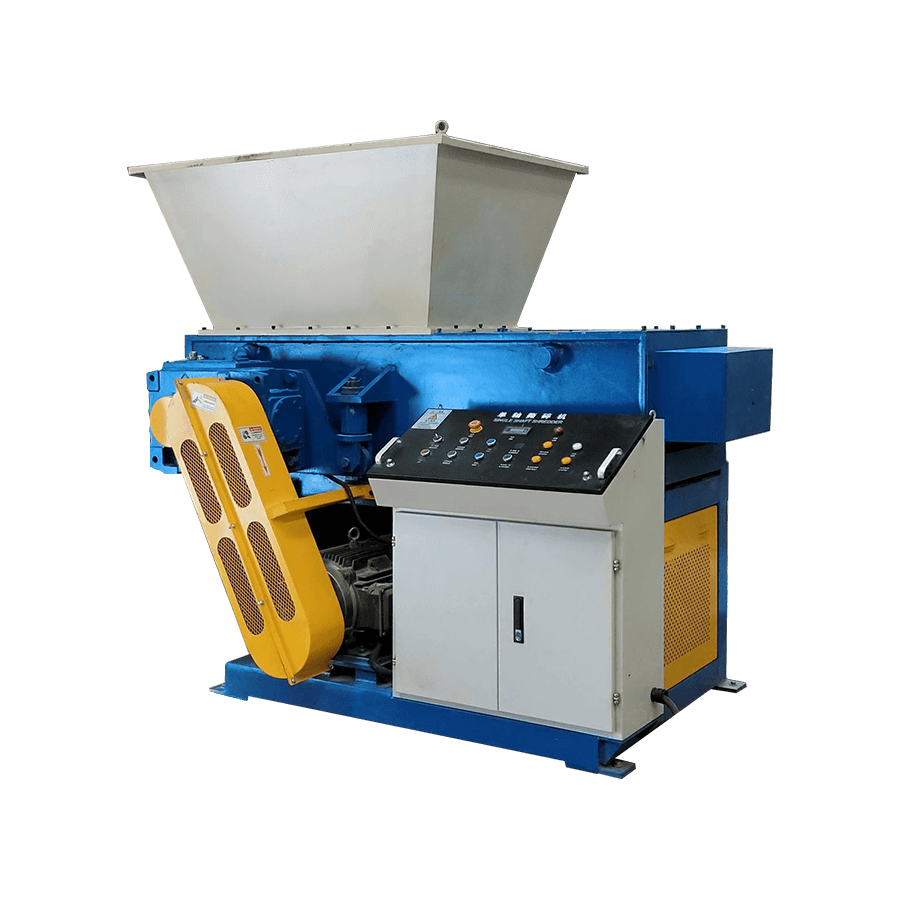

More related cases

The auxiliary machines produced by Henan Reacore are widely used in various production lines. Whether it is the sand and gravel crushing production line in the mining, metallurgy, construction, highway, railway, cement industry, or the waste wire recycling line and waste tire recycling line in the environmental recycling industry, Henan Reacore’s auxiliary machinery can provide you with efficient protection.

Why Choose Us

We have a professional team of engineers who can design and manufacture production solutions according to your needs.

We have a professional modern production workshop, and all the equipment leaving the factory has been quality inspected.

We have many years of manufacturing experience, all equipment is independently developed and produced, the price is more favorable.

We provide a full range of technical support and can provide you with high-quality purchasing services and after-sales services.

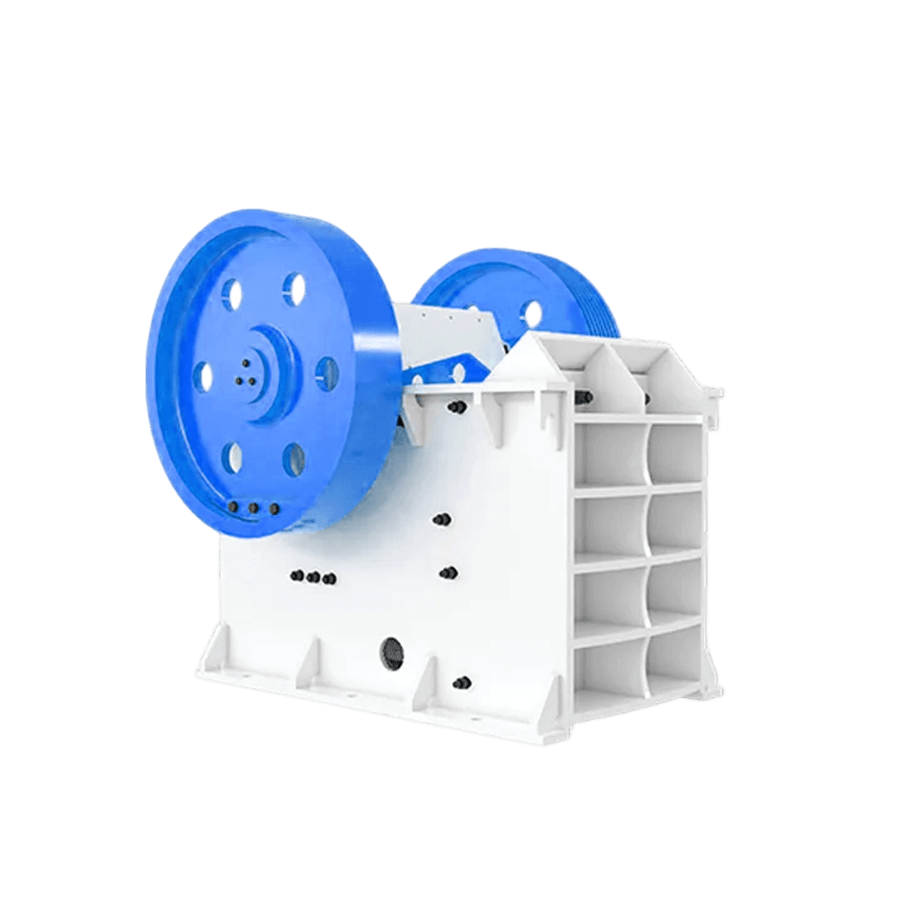

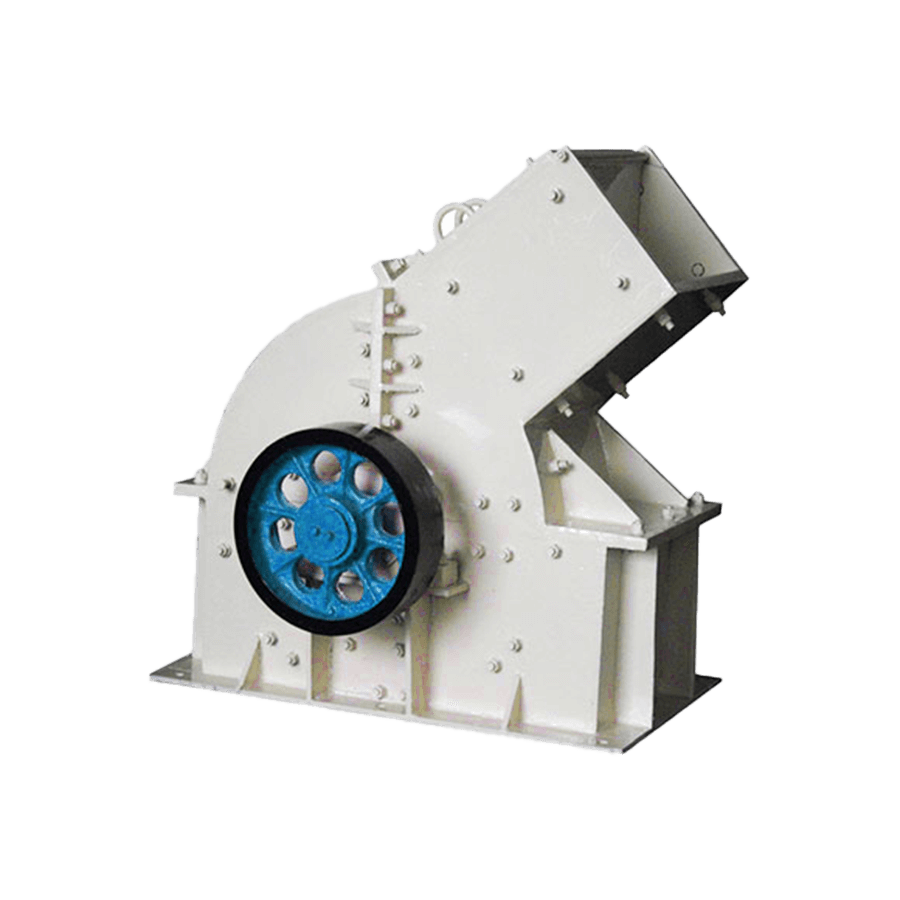

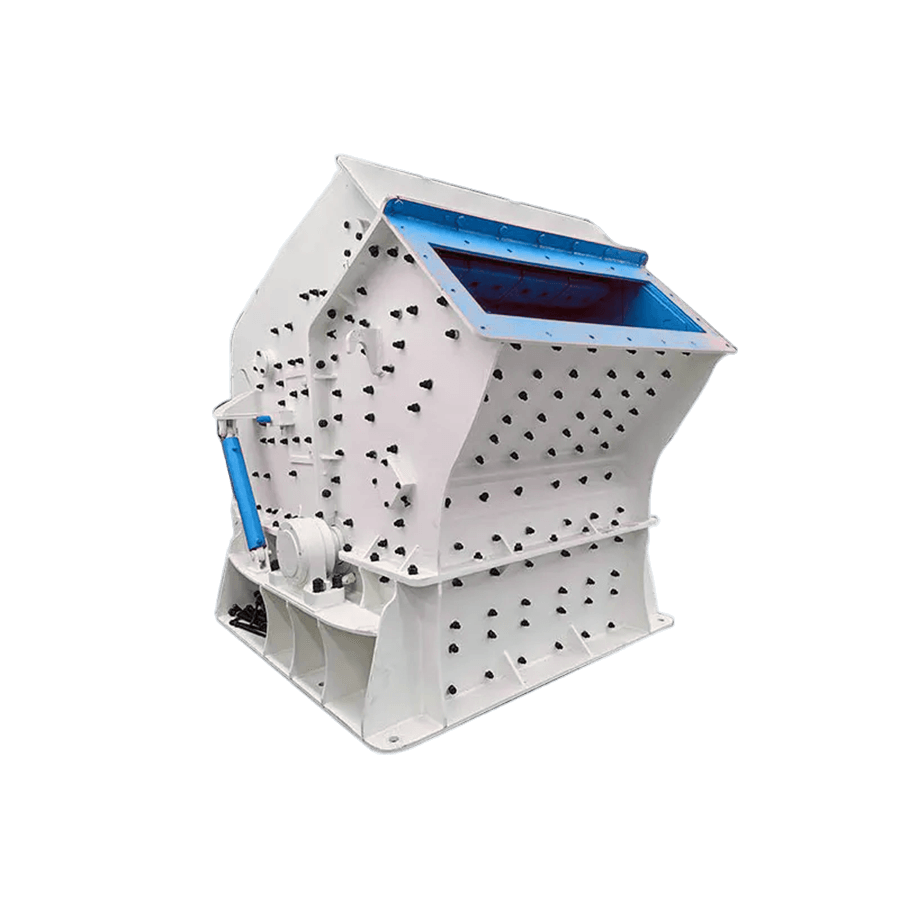

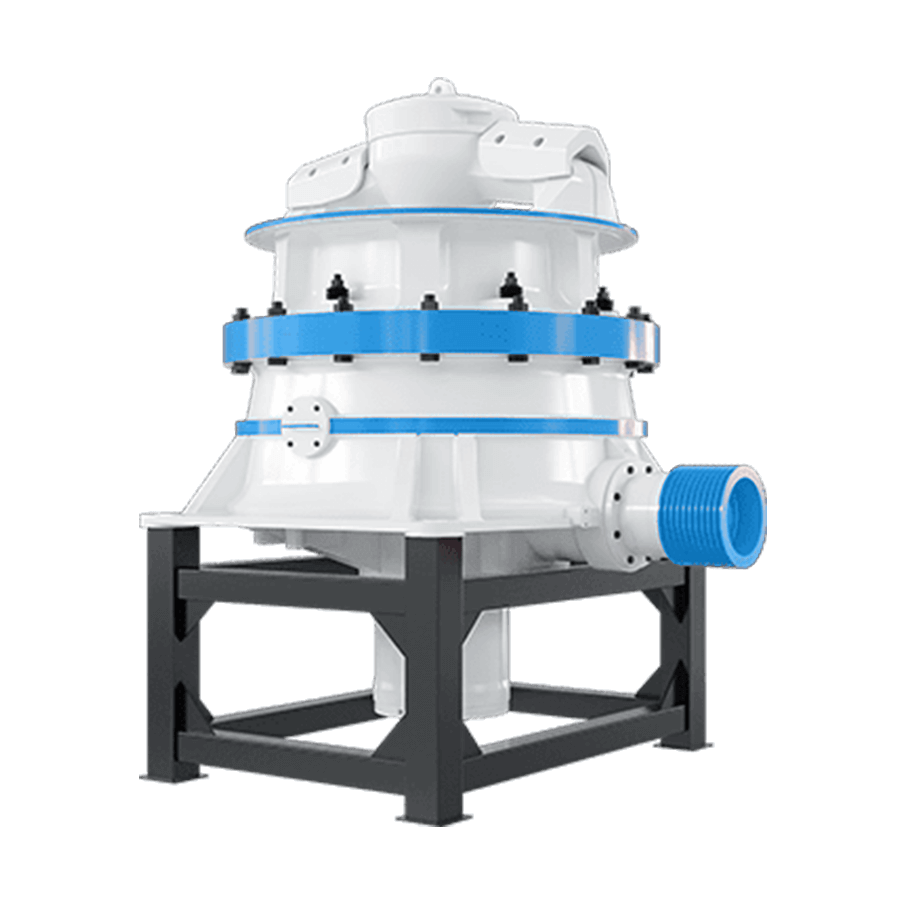

More related products you may want to know

contact us for quote

You can tell us your needs from the following aspects:

1. What is the product name and model you want to know?

2. What type of project do you plan to buy our equipment for?

3. When will you start this project?

4. Where will you carry out your project?

If you don’t know how to choose a specific product, or you need a special project design solution, you can leave your contact information and our technical engineers will design a special solution for you.