In today’s industrial production, the choice of equipment directly affects production efficiency and cost control. As a leading industrial equipment manufacturer. Henan Reacore has launched a popular double-shaft shredder with its innovative design and efficient technology. This article will deeply analyze the advantages and characteristics of Henan Reacore’s double-shaft shredder. Help users better understand how this equipment plays an important role in industrial production.

What is a double-shaft shredder?

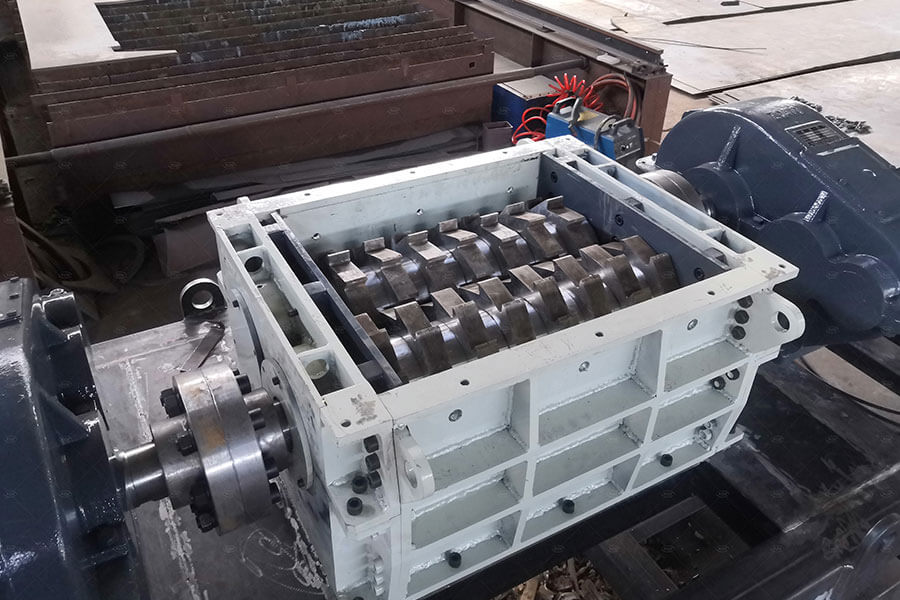

A double-shaft shredder is a mechanical device used to shred various materials, especially for processing waste materials, plastics, rubber, metals and electronic waste. Compared with traditional single-shaft shredders, double-shaft shredders use two independently rotating knife shafts to shred materials through strong tearing and compression. Its advantage is that it can handle a wider variety of materials while providing higher shredding efficiency and better material adaptability.

Unique advantages of Henan Reacore‘s double-shaft shredders

1. Efficient shredding performance

One of the biggest features of Henan Reacore’s double-shaft shredders is its excellent shredding ability. Through precise design and high-quality blade materials, Reacore’s double-shaft shredder can easily handle materials of various difficulties, including hard plastics, rubber, metal, paper and other waste items. Whether it is large pieces of material or fine materials, it can effectively and quickly shred, greatly improving production efficiency.

2. Strong applicability and handling of diverse materials

Henan Reacore’s double-shaft shredder has strong material adaptability and can handle waste materials of different materials. Traditional shredding equipment can often only handle specific types of materials, while Reacore’s double-shaft shredder adopts a flexible adjustment mechanism. Users can easily adjust the knife shaft gap and speed according to needs to adapt to the tearing needs of various materials. Whether it is plastic bottles, waste electrical appliances, or industrial waste, Reacore’s double-shaft shredder can handle it efficiently to meet the needs of different industries.

3. Energy saving and environmental protection, reducing production costs

Nowadays, companies pay more and more attention to energy saving and environmental protection performance when choosing equipment. Reacore’s double-shaft shredders adopts advanced energy-saving technology, which reduces energy consumption and reduces operating costs. At the same time, its efficient crushing capacity means that the equipment can save time and energy when processing large amounts of materials, ensuring that the production process is more environmentally friendly and economical.

4. Stable operating performance, long-term efficient work

After years of technical accumulation and optimization, Henan Reacore’s double-shaft shredder has extremely high stability. Whether it is long-term high-load operation or facing complex material handling tasks, Reacore’s double-shaft shredder can maintain a stable operating state, reduce the failure rate, and increase the service life of the equipment. The high reliability of the equipment not only improves work efficiency, but also reduces maintenance costs and downtime.

5. Safety design to ensure the safety of operators

In the design of industrial equipment, safety is always a key factor that cannot be ignored. Henan Reacore’s double-shaft shredder pays special attention to operational safety, and it adopts advanced protection measures such as overload protection devices, emergency stop buttons, automatic lubrication systems, etc. These designs can effectively avoid machine failures caused by long-term use, while reducing safety hazards caused by improper operation and ensuring the safety of operators.

Why choose Henan Reacore’s double-shaft shredders?

6. Quality assurance, technological innovation

Henan Reacore not only pays attention to the performance and quality of the equipment, but also continues to innovate technology. As a professional industrial equipment manufacturer, Reacore has a strong R&D team. It is committed to improving the technical level of the equipment through continuous innovation and optimization. When users purchase Reacore double-shaft shredders, they can enjoy the technical support and after-sales service provided by the brand. Ensure that the equipment can always be in the best operating state.

7. Multiple customization options to meet different needs

Henan Reacore offers a variety of models and customization options, and users can choose the most suitable double-shaft shredder according to their own production needs. Whether it is processing light waste or heavy metal, Reacore can provide personalized equipment solutions according to customer needs to ensure the maximum efficiency and best cost-effectiveness of the equipment.

Conclusion: Double-shaft shredders leads the new trend of waste treatment

The double-shaft shredder produced by Henan Reacore has become an important equipment in the field of waste treatment and resource recovery in all walks of life with its high efficiency, energy saving and safety. Choosing a high-performance double-shaft shredder is undoubtedly a wise choice to improve production efficiency and reduce costs. Whether in waste treatment, waste material recycling, or environmental protection and resource recycling. Henan Reacore double-shaft shredders provides strong technical support for enterprises, helping them to occupy a favorable position in the fierce market competition.

You are welcome to contact us at any time to get the latest machine quotation and parameters.