With the tightening of environmental protection regulations, the demand for waste tire recycling in Japan is increasing. Henan Reacore‘s waste tire granule production line has been highly recognized in the Japanese market.

Success Case: Application of Waste Tire Granule Production Line in Japan

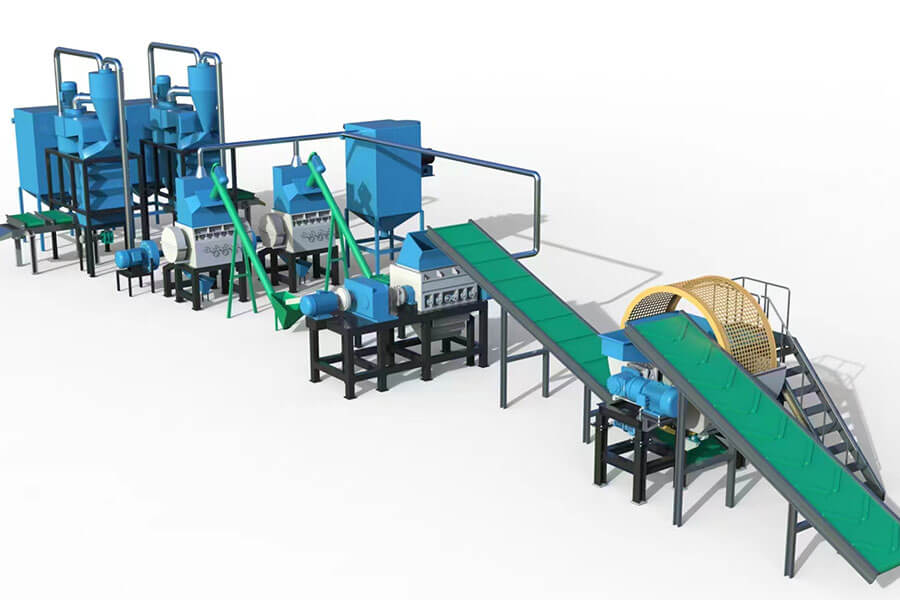

Advantages of waste tire granule production line

Reacore’s waste tire granule production line uses advanced technology to convert waste tires into granular materials. It greatly facilitates subsequent use and reuse. This production line is characterized by high efficiency and environmental protection, which can greatly reduce the stacking and incineration of waste tires. At the same time, the granule products produced are widely used in rubber products, floor mats and other fields.

Application Case: Japanese Tire Recycling Enterprise

Japanese customers used Reacore’s waste tire granule production line to successfully convert waste tires into usable granules. This process not only complies with environmental protection regulations, but also effectively reduces the accumulation of waste and enhances the green image of the company.

Customer Feedback and Success

The company said that by using Reacore’s production line, the processing efficiency of waste tires has increased by 50%. And the company’s revenue has increased through recycled granule products. This case proves the application effect of the waste tire granule production line in the Japanese market and has become a successful example of the company’s environmental protection and profitability.

The above is all about Japan’s waste tire recycling line. If you want to know more about the waste tire recycling line, you can contact us at any time.