Cone Crusher For Sale

Applicable materials:

Pebbles, granite, basalt, iron ore, shale, limestone, gangue, quartz, diabase, marble, copper ore, pebbles, etc.

Feeding size: 60-400 mm

Power: 30-400 Kw

Capcity: 15-2000 T/h

What is a cone crusher

Cone crushers is a medium and fine crushing equipment commonly used in mining, construction, highway, cement and other fields. It is suitable for processing materials with medium to high hardness. It crushes materials through the gap between the rotating crushing cone and the fixed crushing wall. It has a high crushing ratio, production efficiency and particle quality in the crushing process.

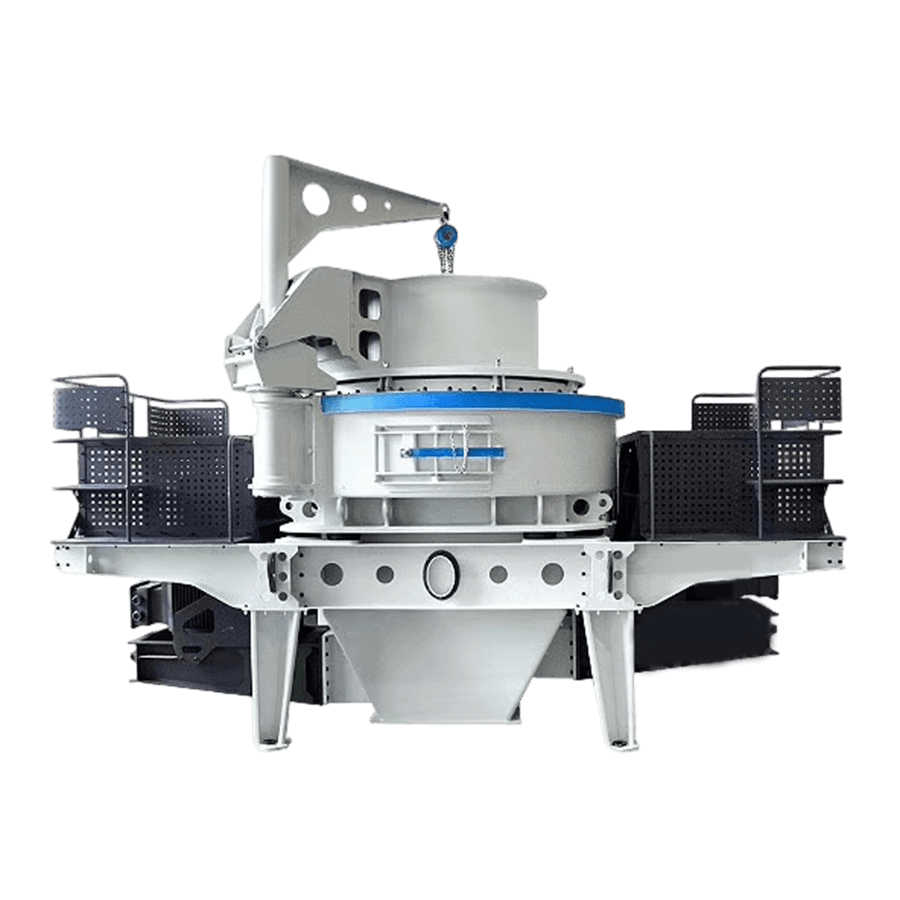

Types of cone Crusher We Sale

The cone crushers produced by Henan Reacore are suitable for fine crushing operations in various aggregate production lines. According to the different cavity shapes and appearances, they can be divided into spring cone crushers, Simmons cone crushers, single-bar hydraulic cone crushers, and multi-cylinder hydraulic cone crushers.

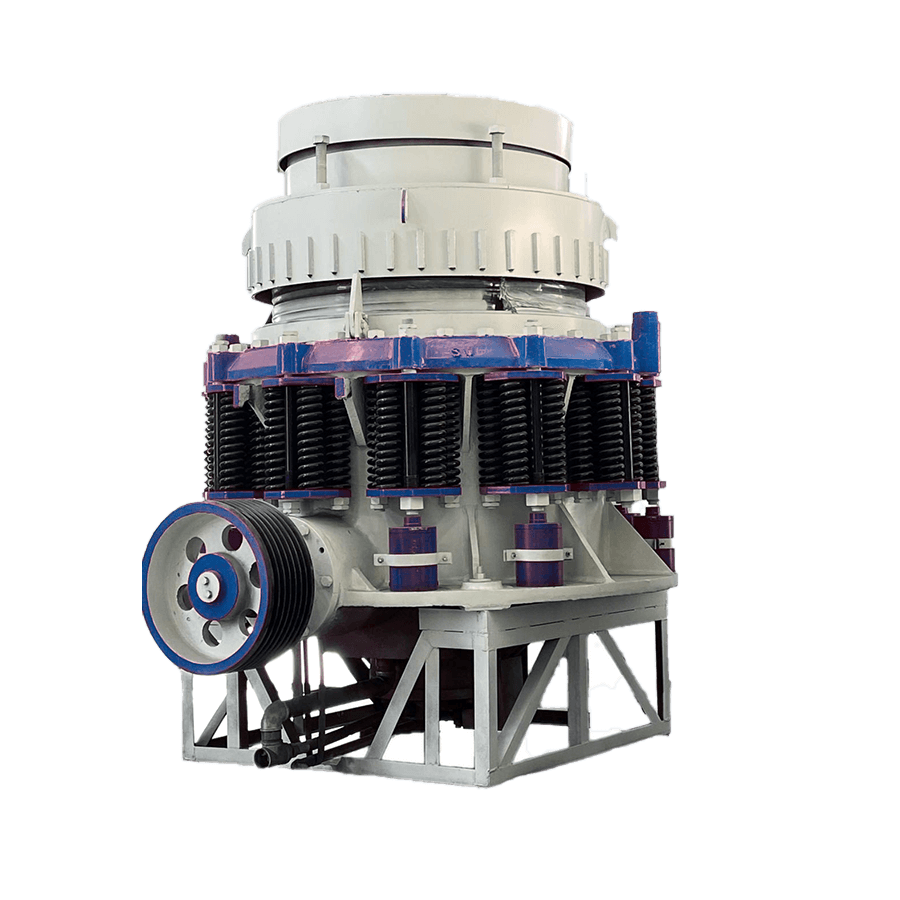

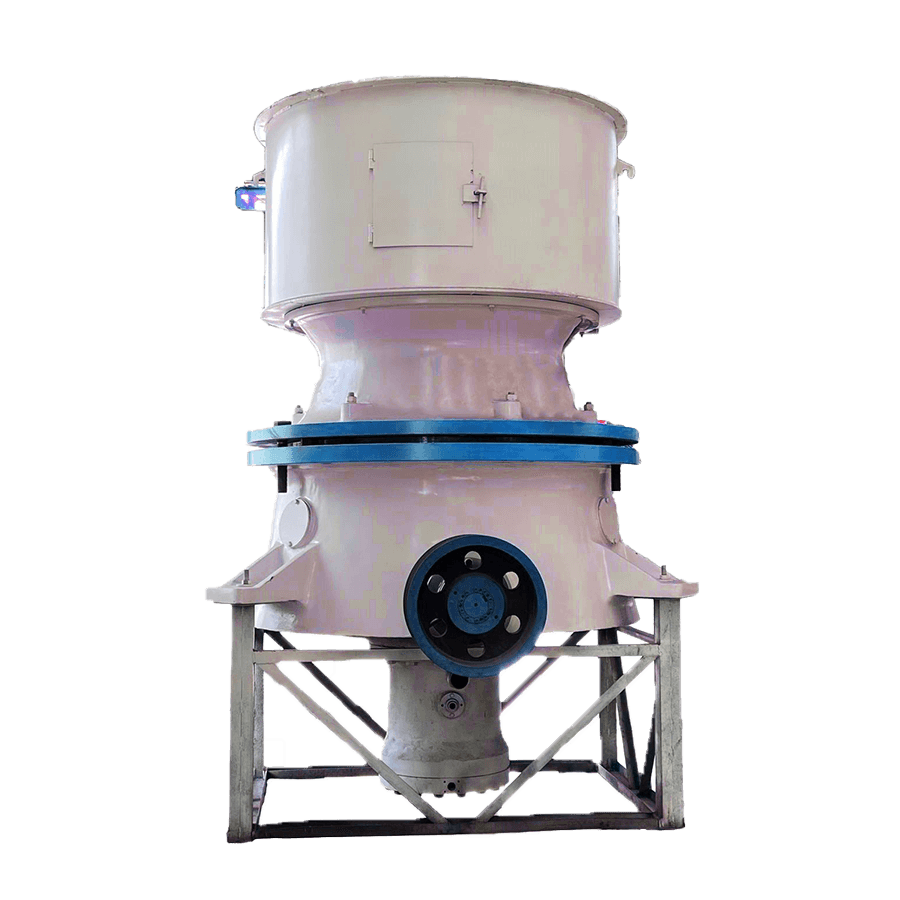

Spring Cone Crusher

Spring cone crushers is a medium and fine crushing equipment, the spring is not only a safety device but also affects the crushing force. The crushing chamber type is determined by the ore use: the standard type is suitable for medium crushing, the medium type is suitable for fine crushing, and the short head type is suitable for ultrafine crushing.

Spring Cone crushers

Henan Reacore’s spring cone crushers have a variety of cavity types to choose from. (PYB, PYD, PYZ)

Capacity: 5-1000 t/h

Feeding size: 65-300 mm

Voltage:220v/380v/415v/440v/480v

Symons Cone Crusher

Simmons cone crushers is a new generation product of spring cone crusher which is improved, optimized and upgraded. It is based on the principle of laminated crushing and has developed into a modern high-performance cone crusher that integrates high swing frequency, optimized cavity shape and reasonable stroke.

Symons Cone crushers

The Simmons cone crusher produced by Henan Reacore has optimized cavity design, greatly increasing production capacity and performance.

Capacity: 9-2000 t/h

Feeding size: 60-400 mm

Voltage:220v/380v/415v/440v/480v

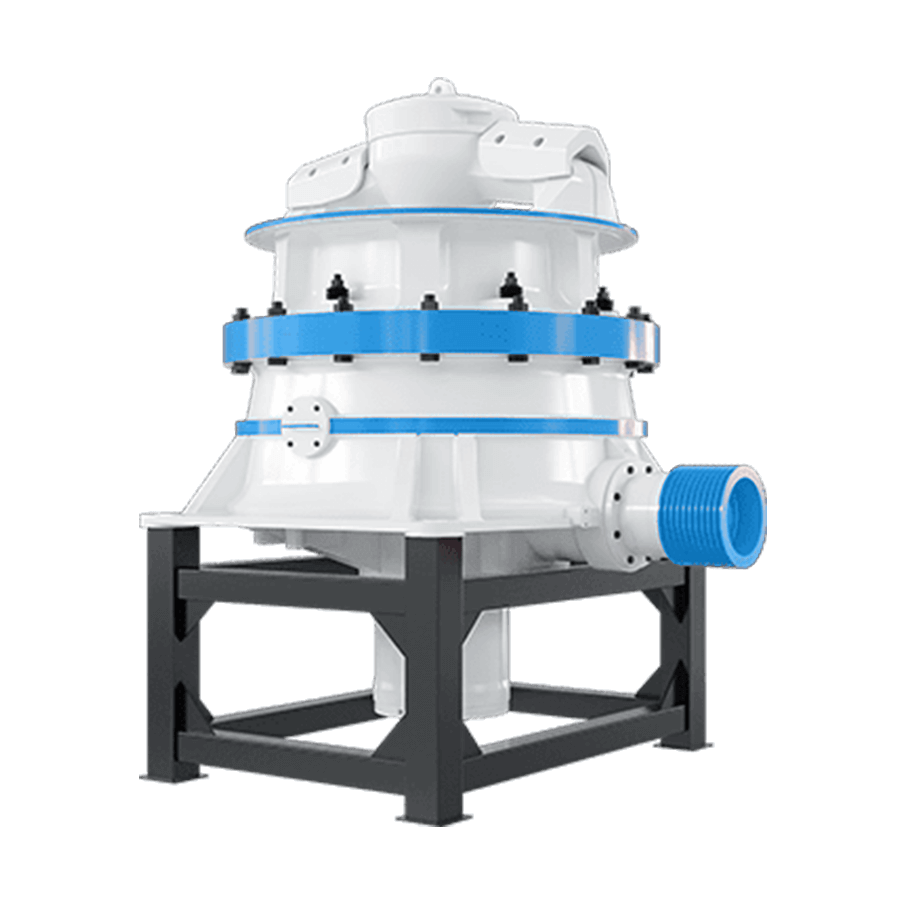

Single-cylinder Hydraulic Cone Crusher

The single-cylinder hydraulic cone crushers uses a single hydraulic cylinder to lift the cone to achieve multiple functions such as discharge port adjustment, cavity cleaning, iron discharge and overload protection. Equipped with an electronic intelligent discharge port control system, it can achieve more production process control and optimization functions.

Single-cylinder Hydraulic Cone Crushers

The single-cylinder hydraulic cone crusher produced by Henan Reacore adopts an upper and lower double-support design, which makes the machine have higher crushing efficiency.

Capacity: 40-1000 t/h

Feeding size: 60-480 mm

Voltage:220v/380v/415v/440v/480v

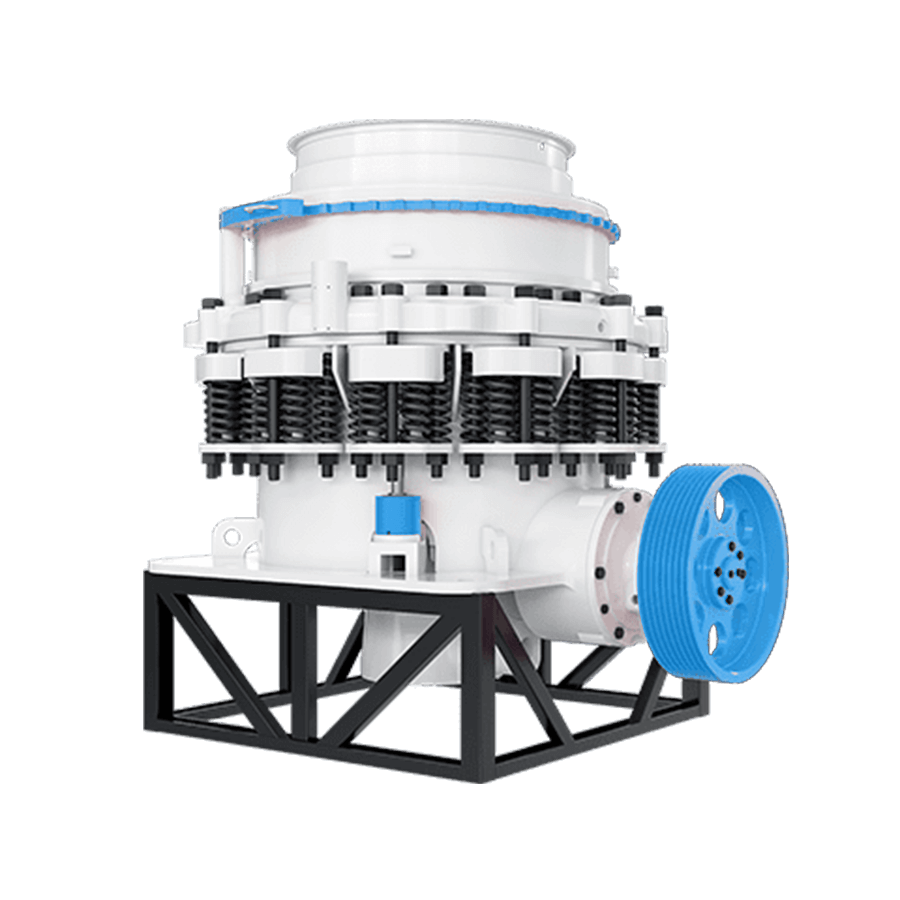

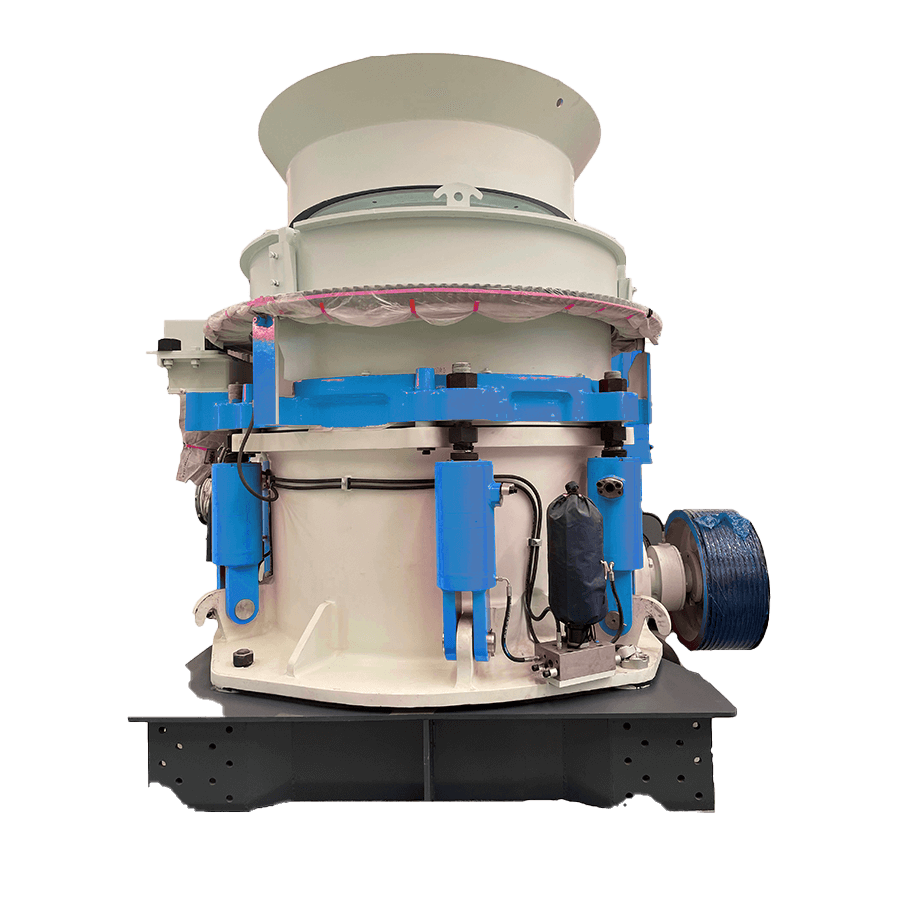

Mulity-cylinder Hydraulic Cone Crusher

The multi-cylinder hydraulic cone crushers is a medium and fine crushing equipment. It uses a hydraulic system to adjust the discharge port and is used to protect the cone crusher from overload. The hydraulic and lubrication systems use double insurance control and are widely used in mining and sand and gravel aggregate industries.

Mulity-cylinder Hydraulic Cone Crushers

The multi-cylinder hydraulic cone crusher produced by Henan Reacore adopts high-quality components, optimizes the wear parts, and the machine has a longer service life.

Capacity: 8-95 t/h

Feeding size: 1-250 mm

Voltage:220v/380v/415v/440v/480v

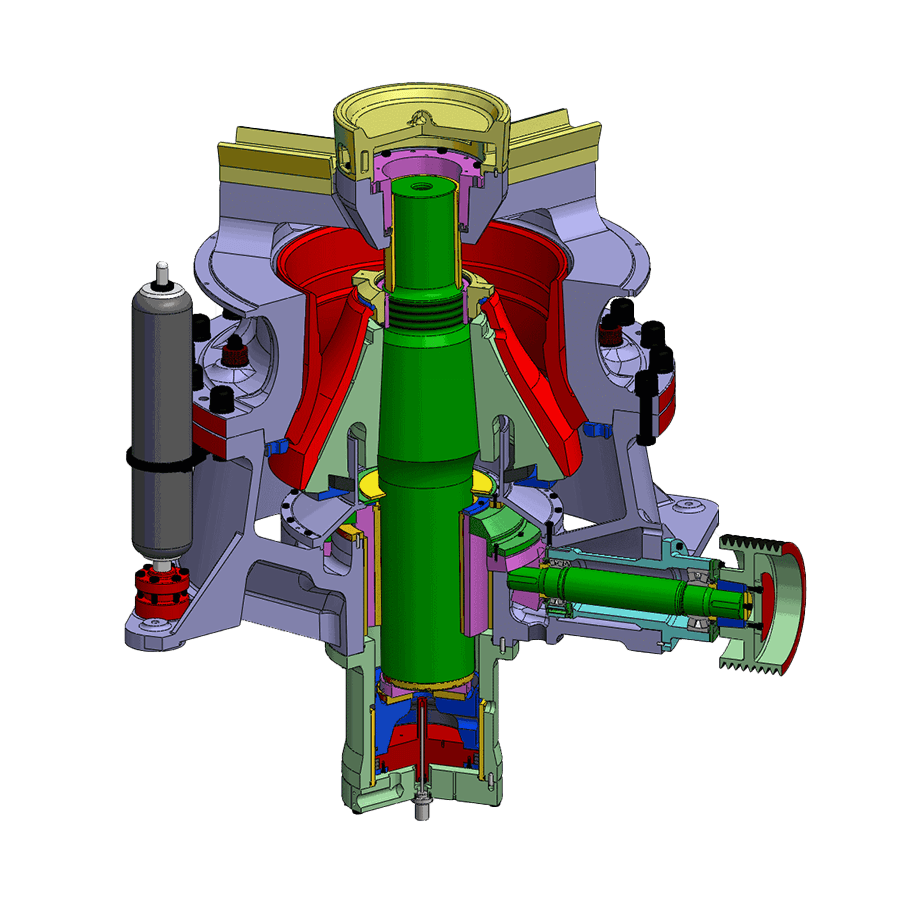

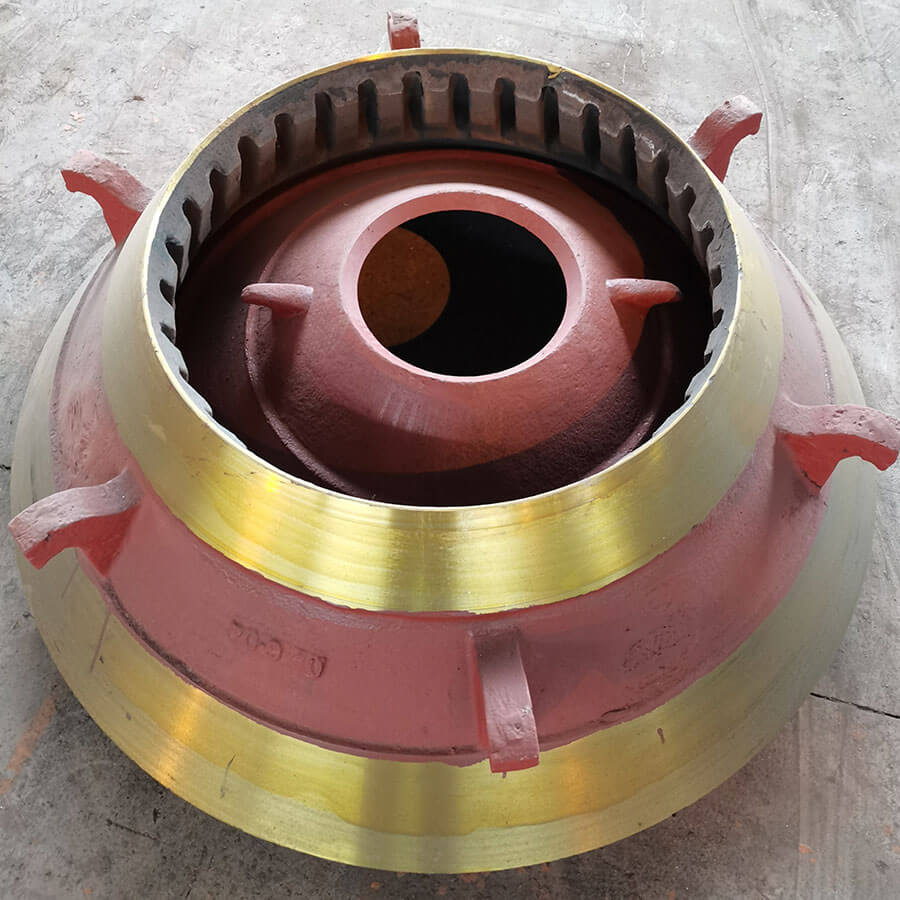

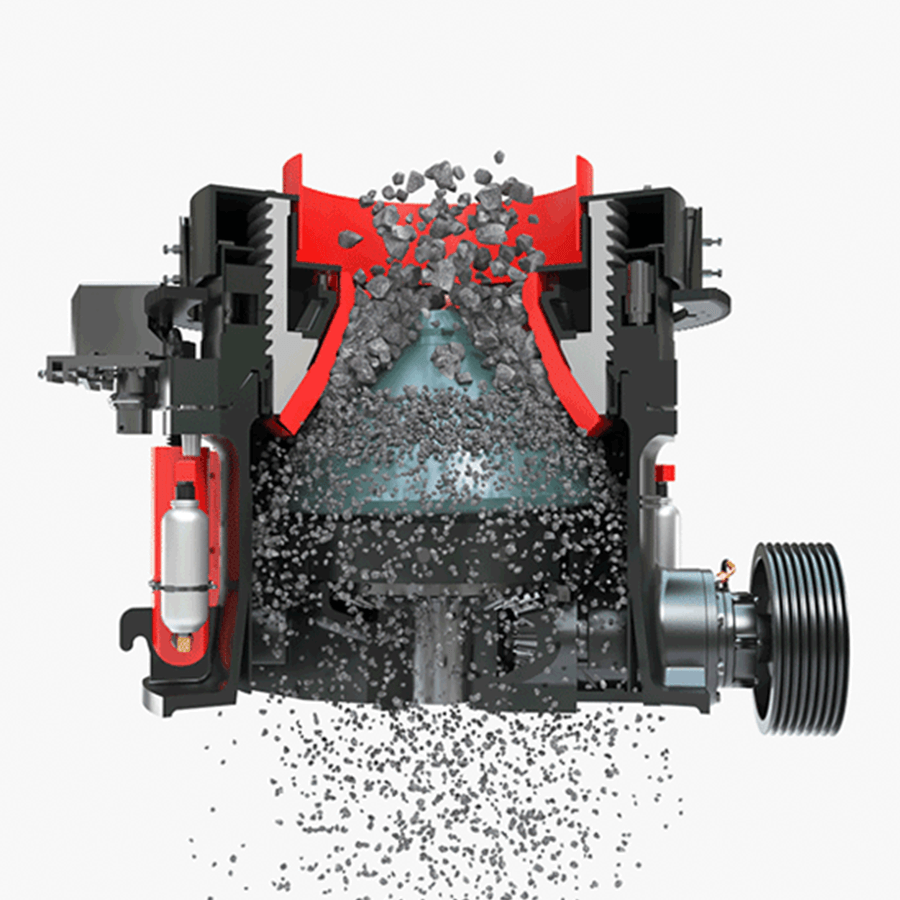

Product Structure

Mainframe: includes a moving cone and a fixed cone. The moving cone is driven to rotate by an eccentric sleeve. The fixed cone is round or concave and is responsible for receiving the crushed material.

Motor: drives the crusher to work. Common ones include motors and hydraulic drive devices.

Eccentric shaft: drives the moving cone to rotate. It is integrated with the mainframe and the eccentric shaft is driven by gears.

Crushing chamber: formed by the moving cone and the fixed cone, it is the main area for material crushing.

Hydraulic system: used to adjust the size of the crushing chamber to protect the equipment from overload.

Discharge port adjustment device: used to adjust the size of the discharge port to control the particle size of the finished product.

Spring/hydraulic protection system: when the crusher is overloaded due to the entry of too large materials, the spring or hydraulic system will automatically adjust to restore the crusher to normal operation.

How it works

As the rock enters the top of the crusher, it is squeezed between the crushing wall and the bowl-shaped liner or concave surface due to the rotation of the eccentric main shaft, which creates compression in the crushing chamber. As the opening of the crushing chamber gradually narrows, the rock moves downward through the wear-resistant liner and its size gradually decreases. After the large pieces of ore are crushed once, they fall to a lower position and are crushed again. This process continues until the rock is small enough to fall through the narrow opening at the bottom of the crusher. The final particle size and crushing ratio depend on the closed side setting or the gap between the two crushing parts at the lowest point.

Application Areas

Cone crushers is a kind of crushing equipment widely used in mining, metallurgy, construction, highway, railway, cement and other industries. It is mainly used for medium crushing of various materials with high hardness.

Product Advantages

1. High efficiency and high production capacity: It has a higher crushing efficiency among similar crushing equipment, especially when processing materials with higher hardness, it can produce a larger output.

2. Smaller discharge particle size: By adjusting the discharge port, the particle size of the product can be accurately controlled to ensure the uniform particle shape of the crushed material.

3. Lower energy consumption: Due to its optimized structure, the lower energy consumption makes its operating cost lower.

4. High stability and reliability: The hydraulic protection device and spring protection system are used to effectively avoid equipment damage caused by overload and ensure the long-term stable operation of the equipment.

5. Strong adaptability: It is suitable for crushing various materials with medium to high hardness, and is widely used in mining, construction, metallurgy, chemical industry and other industries.

6. Easy to maintain: The simplified design makes it easy to repair and replace parts, and its durability is strong, which can reduce downtime.

7. High degree of automation: Equipped with hydraulic adjustment and automatic control system, it is more convenient to operate and can effectively improve production efficiency.

Product Parameters

| Model | Cone Diameter(mm) | Discharge opening adjustment range(mm) | Max feeding size(mm) | Capacity(t/h) | Power(kw) | Overall dimension(mm) |

| PYB600 | 600 | 12-25 | 65 | 15-25 | 30 | 1740x1225x1940 |

| PYD600 | 600 | 3-13 | 36 | 5-10 | 30 | 1740x1225x1940 |

| PYB900 | 900 | 15-50 | 115 | 50-90 | 55 | 1990x1640x2380 |

| PYZ900 | 900 | 5-20 | 60 | 20-65 | 55 | 1990x1640x2380 |

| PYD900 | 900 | 3-13 | 40 | 15-50 | 55 | 1990x1640x2380 |

| PYB1200 | 1200 | 20-50 | 145 | 110-200 | 110 | 2805x2300x2980 |

| PYZ1200 | 1200 | 8-26 | 100 | 50-150 | 110 | 2805x2300x2980 |

| PYD1200 | 1200 | 3-15 | 50 | 18-105 | 110 | 2805x2300x2980 |

| PYB1750 | 1750 | 25-60 | 215 | 280-480 | 160 | 3610x2950x4185 |

| PYZ1750 | 1750 | 10-30 | 185 | 115-320 | 160 | 3610x2950x4185 |

| PYD1750 | 1750 | 5-15 | 85 | 75-230 | 160 | 3610x2950x4185 |

| PYB2200 | 2200 | 30-60 | 300 | 590-1000 | 280 | 4790x3430x5080 |

| PYZ2200 | 2200 | 10-30 | 235 | 200-580 | 280 | 4790x3430x5080 |

| PYD2200 | 2200 | 5-16 | 110 | 120-370 | 280 | 4790x3430x4852 |

| The above parameters are only for spring cone crushers. If you need other types of parameters, please contact us. | ||||||

Have you decided on the model you want to buy? If you can’t find the model you want, please contact us for consultation.

More related cases

The cone crushers produced by Henan Reacore can be used for ore crushing. Whether it is the crushing operation in mining, metallurgy, construction, highway, railway, cement industry, or the secondary crushing in the sand and gravel production process, Henan Reacore’s cone crushers is your best choice.

Why Choose Us

We have a professional team of engineers who can design and manufacture production solutions according to your needs.

We have a professional modern production workshop, and all the equipment leaving the factory has been quality inspected.

We have many years of manufacturing experience, all equipment is independently developed and produced, the price is more favorable.

We provide a full range of technical support and can provide you with high-quality purchasing services and after-sales services.

More related products you may want to know

contact us for quote

You can tell us your needs from the following aspects:

1. What is the product name and model you want to know?

2. What type of project do you plan to buy our equipment for?

3. When will you start this project?

4. Where will you carry out your project?

If you don’t know how to choose a specific product, or you need a special project design solution, you can leave your contact information and our technical engineers will design a special solution for you.