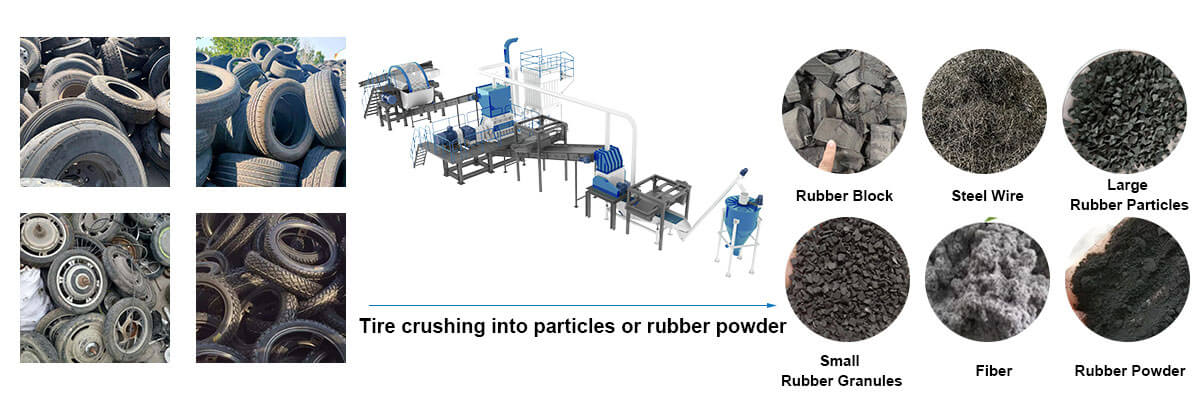

Waste Tire Recycling Plant For Sale

Applicable materials:

Waste car tires, bicycle tires, truck tires, tricycle tires, rubber tires, rubber soles, waste water pipes, rubber conveyor belts and other waste rubber products.

Output: 5-8cm rubber block, 3-20mm rubber granule, 5-80mesh rubber powder

Power: 20-220 Kw

Capcity: 500-5000 kg/h

What is a Waste tire recycling production line

The waste tire recycling production line is a device specially used to process waste tires. Its main purpose is to convert waste rubber tires into reusable resources. Through this production line, waste tires can be effectively decomposed and valuable materials such as rubber, steel wire and fiber can be recycled.

The recycled rubber can be used to make recycled rubber, asphalt, rubber runways, etc., while steel wire and fiber can also be reused. The waste tire recycling production line can not only reduce environmental pollution, but also contribute to the reuse of waste resources.

Types of Waste tire recycling production line We Sale

The waste tire recycling production line produced by Henan Reacore is a kind of equipment specially used for processing waste tires. According to the different finished materials, it can be divided into various types of production lines: tire block production line, tire particle production line, tire grinding production line

Tire block production line: mainly shreds the tire into 50-100mm rubber blocks through a series of shearing.

Tire pellet production line: mainly shreds the shredded tire rubber blocks into 3-20mm rubber particles.

Tire grinding production line: mainly grinds the shredded tire rubber blocks into 5-80mesh rubber powder.

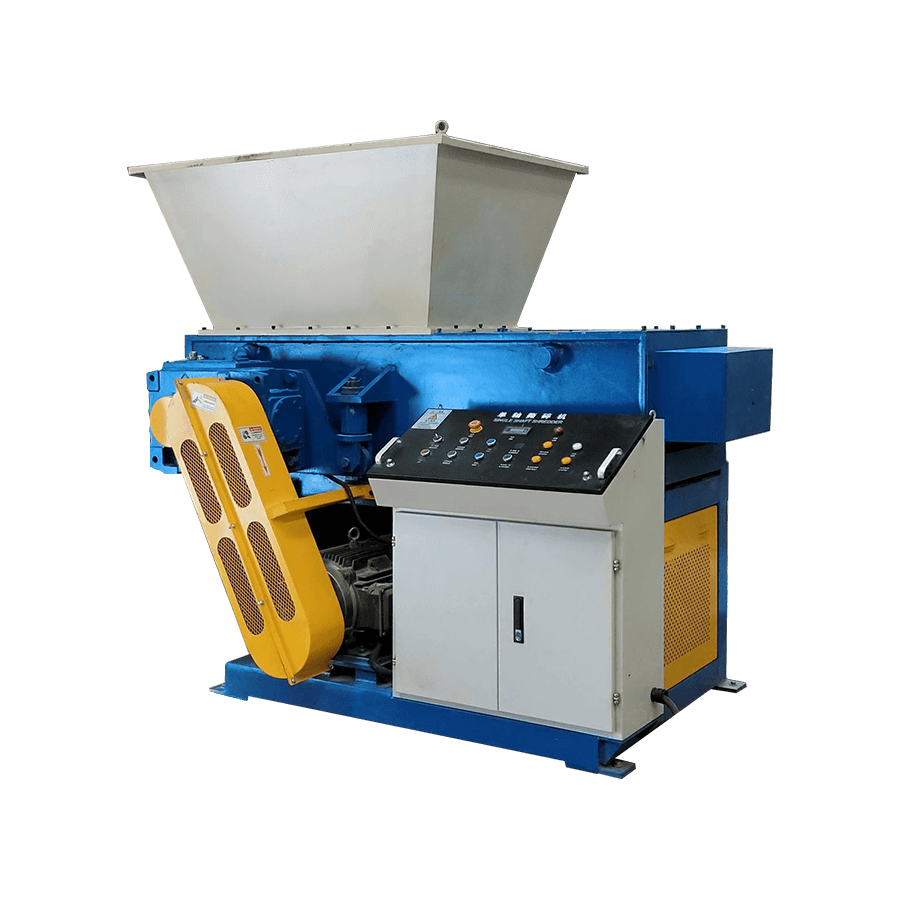

Tire cutting equipment

Tire cutting equipment is also called tire pre-processing equipment, which refers to the equipment that recycles the tire bead steel wire and tire rubber blocks through a series of operations such as shearing, cutting, stripping, cutting, wire grinding, and wire drawing.

The equipment included in this process includes: tire hydraulic shears, tire bead cutting machines, tire strip cutting machines, tire cutting machines, tire wire grinding machines, tire wire drawing machines, tire shredders, etc.

small Tire cutting equipment

Tire cutting equipment uses fully automatic tire block making machine or tire circle cutting machine, tire strip cutting machine, tire block cutting machine and other equipment to cut waste tires into 50-100mm rubber blocks.

Capacity: 1-3 t/h

Finished material: 50-100 mm

Voltage:220v/380v/415v/440v/480v

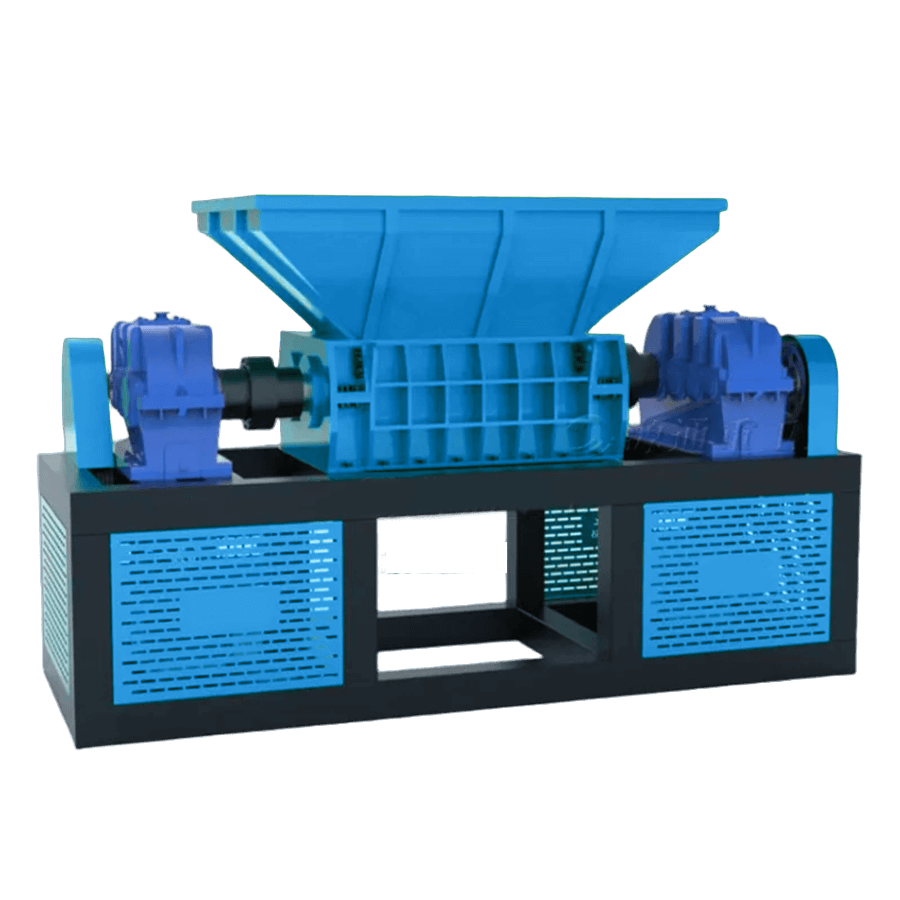

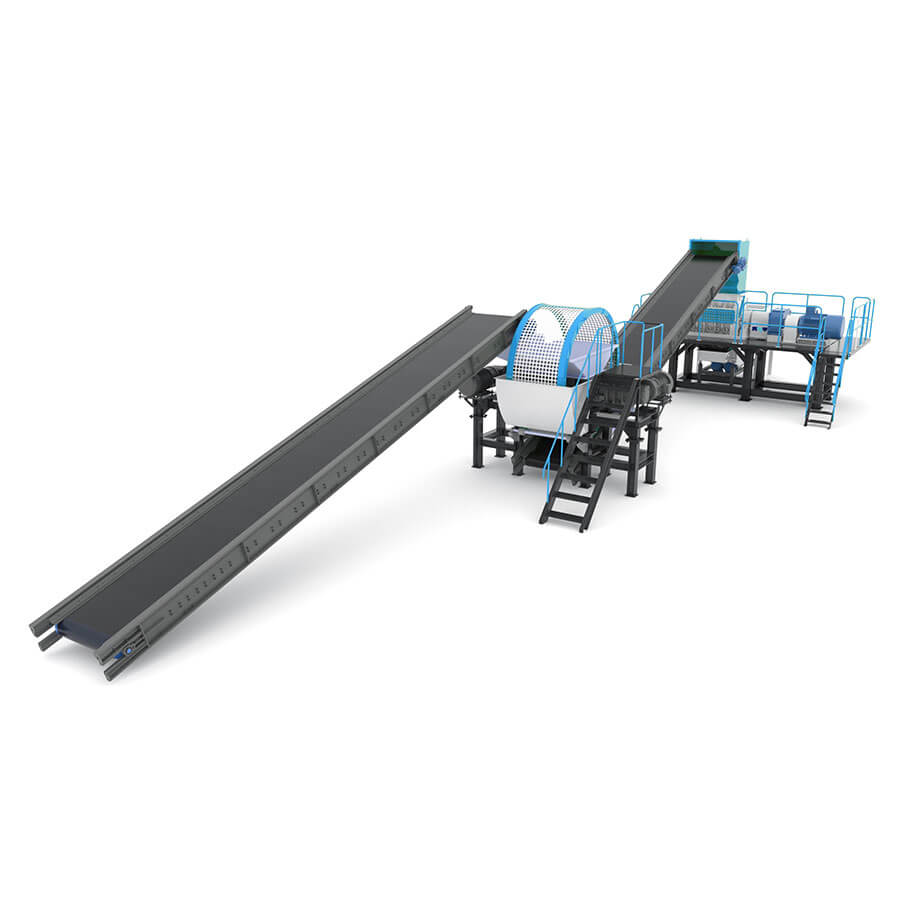

tire Double shaft shredder

The tire shredder mainly shreds the waste tires through double shafts and then drops them into the screen. When the screen rotates, it drives the larger rubber blocks back to the shredder for shredding.

Capacity: 1-10 t/h

Finished : 50-100 mm(Adjustable)

Voltage:220v/380v/415v/440v/480v

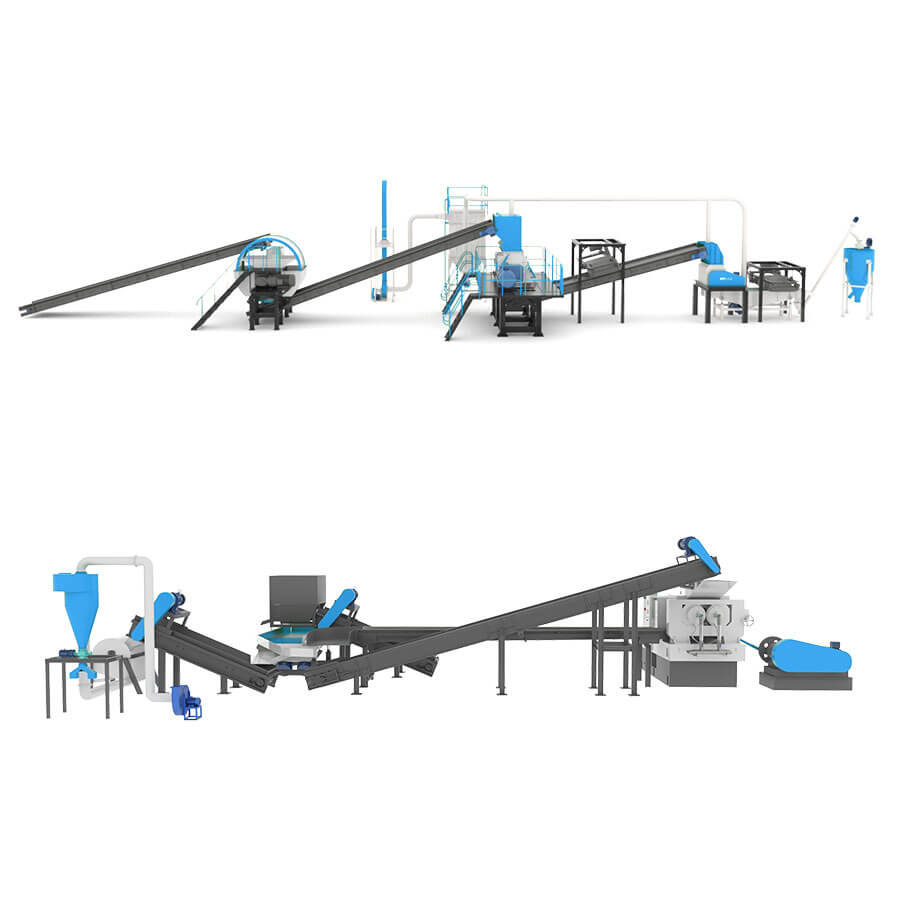

Tire pellet production line

The tire pellet production line is an equipment system that processes waste tires into pellets. It separates the rubber, fiber and steel wire in the tires through tearing, crushing, screening and other processes, so that the waste tires can be recycled.

The tire pellet production line can usually produce rubber pellets of different specifications, and the production line configuration can be changed according to user needs. For example, 2-3 mm small rubber pellet production line, 3-5 mm medium rubber pellet production line, 15-20 mm large rubber pellet production line, etc.

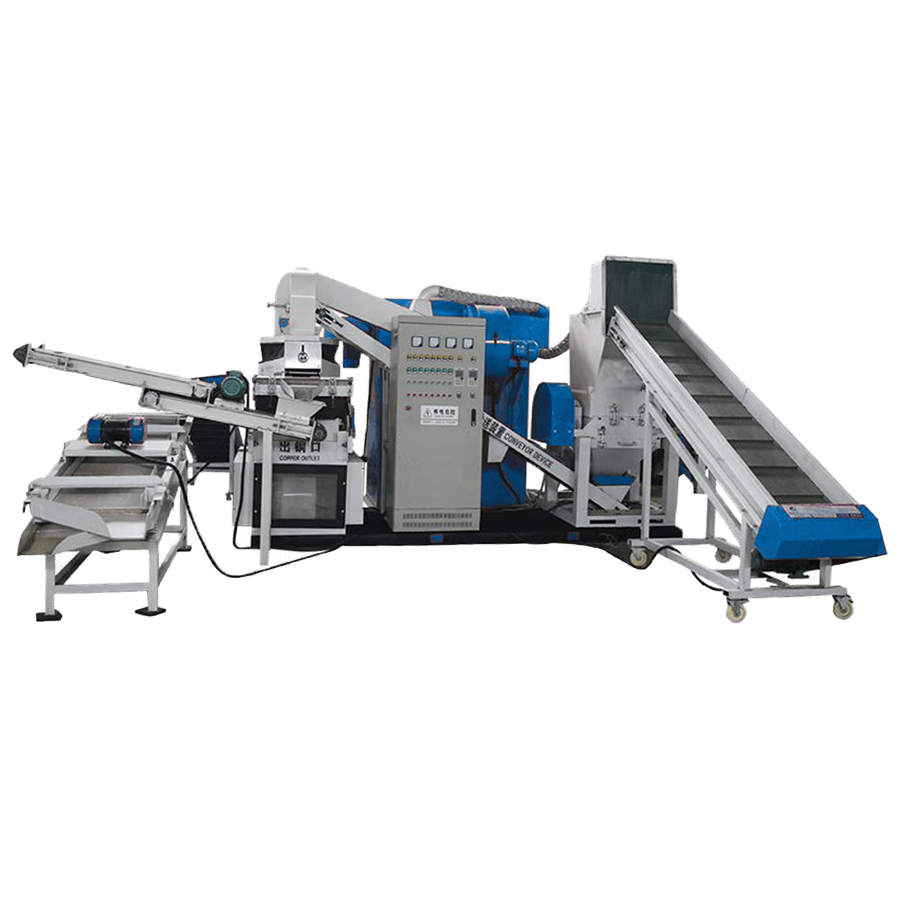

Simple rubber pellet production line

This simple rubber granule production line mainly uses a tire double-shaft shredder and a wire separator as the production host, which can produce large rubber granules of 10-30mm.

Capacity: 0.5-4 t/h

Discharge size: 10-30 mm

Voltage:220v/380v/415v/440v/480v

Tire pellet production line

The tire pellet production line uses tire shredder, steel wire separator, rubber pellet machine, fiber separator and other equipment to produce 3-10mm rubber pellets.

Capacity: 0.5-4 t/h

Discharge size: 3-10 mm

Voltage:220v/380v/415v/440v/480v

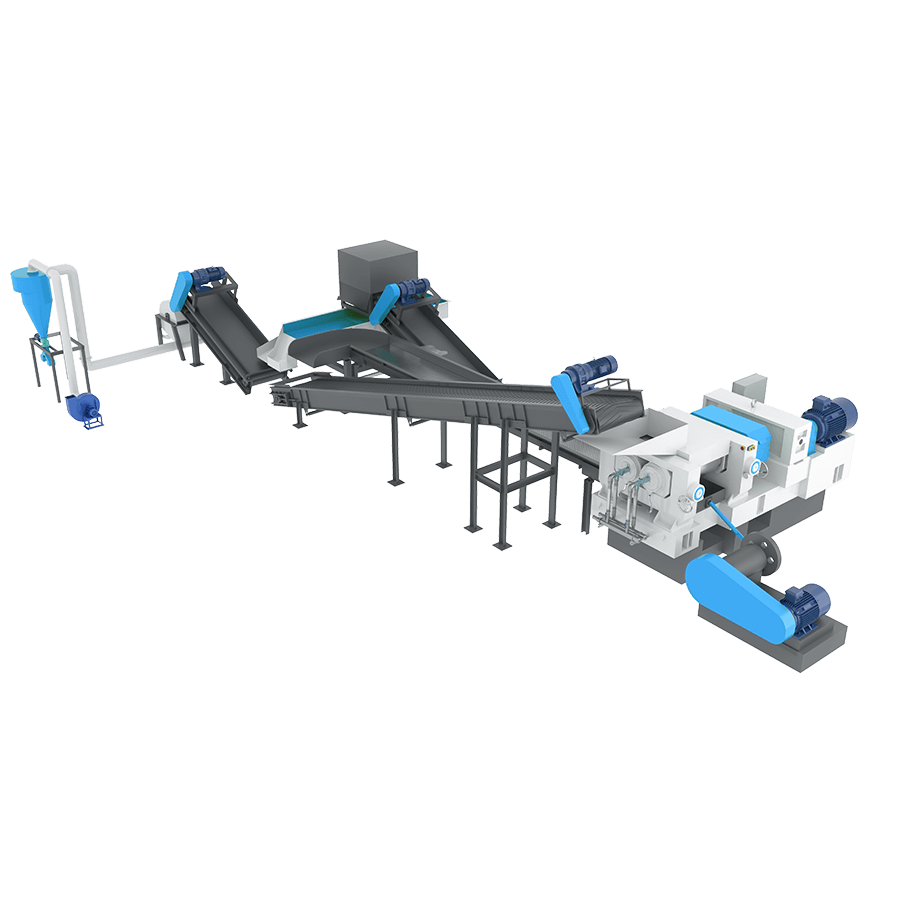

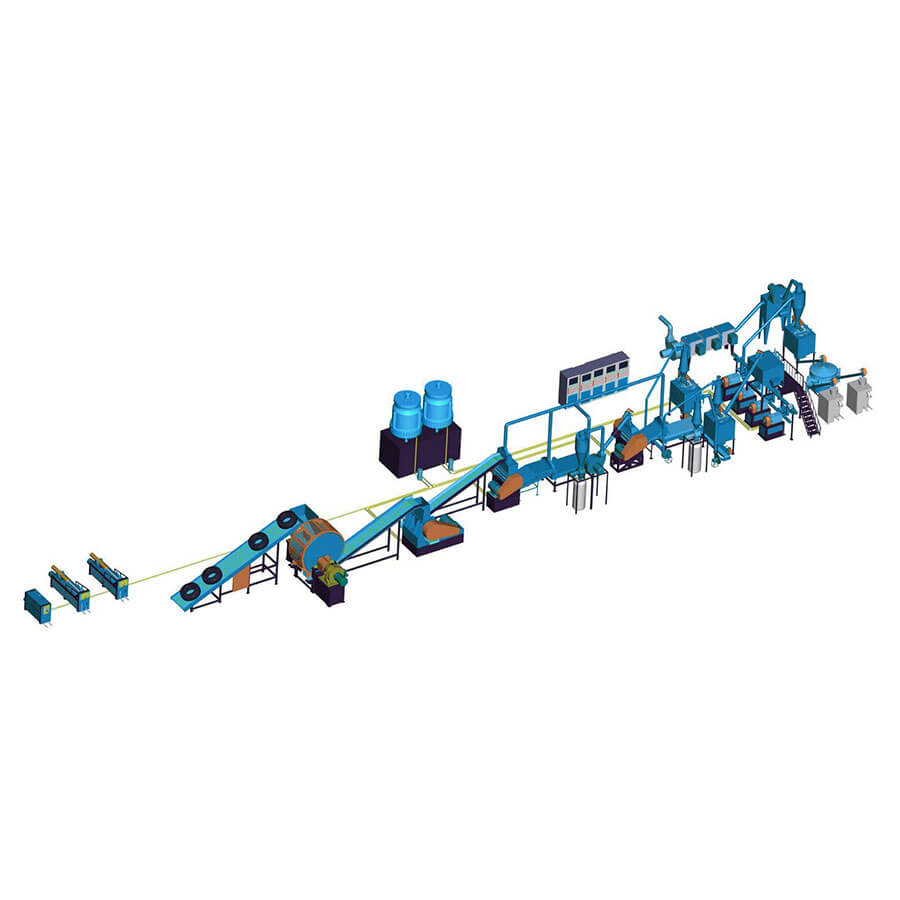

Tire rubber power production line

The tire rubber power production line is an equipment system that processes and grinds waste tires into powder. Compared with the tire particle production line, the core of the grinding production line is to process waste tires into finer powder, which is usually used for further resource utilization or as raw materials to enter other production links.

The tire grinding production line is mainly equipped with tire double-shaft shredder, double-roll rubber crusher, magnetic separator, vibrating screen and other equipment.

Simple tire grinding power production line

The tire grinding production line mainly adopts tire double-shaft shredder and double-roll crusher, which can crush various waste tires into 20-80mesh rubber powder.

Capacity: 0.5-2 t/h

Discharge size: 20-80 mesh

Voltage:220v/380v/415v/440v/480v

Tire rubber powder production line

The modified tire rubber powder production line mainly adopts tire double-shaft shredder, wire separator, tire granulator, tire grinder and other equipment, which can crush waste tires into 20-120mesh rubber powder.

Capacity: 0.5-2 t/h

Discharge size: 20-120 mesh

Voltage:220v/380v/415v/440v/480v

Product Structure

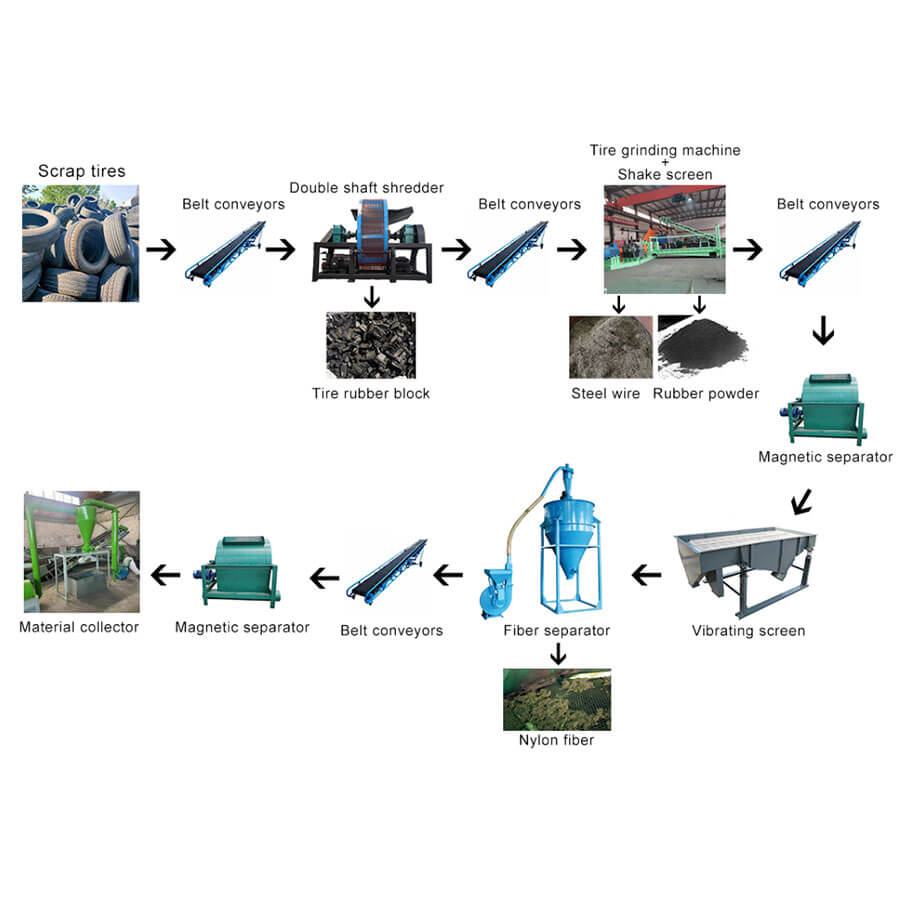

The waste tire recycling production line will adopt different equipment configuration schemes according to different finished materials. Common configuration schemes can be divided into: tire pretreatment equipment, tire block production line equipment, tire particle production line equipment, and tire grinding production line equipment.

Tire pretreatment equipment: usually includes double-axis shredders, gantry shears, tire circle cutting machines, tire strip cutting machines, tire wire drawing machines, tire wire grinding machines, etc.

Tire block production line equipment: usually includes fully automatic tire block breaker and tire shredder, etc.

Tire particle production line equipment: usually includes shredders, wire separators, rubber particle machines, magnetic separators, fiber separators, linear vibrating screens, etc.

Tire grinding production line equipment: usually includes shredders, double-roll rubber breakers, magnetic separators, vibrating screens, etc.

How it works

Waste tires are crushed into sizes suitable for entering the double-shaft shredder through pre-treatment equipment (gantry shears or other shearing equipment). After being further shredded into small pieces of tire rubber blocks by the double-shaft shredder, they are processed again to make rubber particles or rubber powder.

Rubber particles: The shredded tire rubber blocks are further crushed into larger rubber particles by the wire separator, and the steel wire and rubber are separated. After that, the steel wire is selected by the magnetic separator, and the other rubber particles are transported to the rubber particle machine through the screw conveyor for crushing. The crushed rubber particles are screened by the linear vibrating screen to obtain rubber particles of different sizes.

Rubber powder: The shredded tire rubber blocks are ground by the double-roll rubber crusher and then screened by the shaking screen. The qualified rubber powder is packaged after the steel wire is selected by the magnetic separator. The unqualified rubber blocks and rubber particles are returned to the double-roll rubber crusher for another grinding operation.

Application Areas

After a series of recycling, the rubber particles and rubber powder in waste tires can be used to pave rubber tracks and sports fields, and to manufacture environmentally friendly products such as rubber floor mats, shock-absorbing pads, and floor tiles. Some of the rubber powder can also be used as fillers for plastic or rubber products, wall spraying materials, industrial fuels, etc.

Product Advantages

1. Environmental protection and energy saving: The physical decomposition technology is adopted to avoid the pollution of waste tires to the environment. Through recycling and treatment, the pollution of waste tires to land and water sources is reduced, which is conducive to environmental protection.

2. Resource reuse: Through the recycling production line, the rubber, steel wire, fiber and other materials of waste tires can be fully reused, reducing resource waste and improving resource utilization.

3. Efficient processing: The production line adopts advanced technology and equipment and has the ability to efficiently process waste tires. It can quickly process a large number of waste tires to meet the needs of large-scale production.

4. Reduce costs: The high efficiency and automatic control of the production line reduce operating costs, reduce labor costs, and improve production efficiency.

5. Automatic control: Equipped with an automatic control system, it can monitor and adjust the production process in real time, which improves the ease and safety of operation of the production line.

6. Versatility: This production line is not only suitable for the recycling of waste automobile tires, but also suitable for processing other rubber wastes, such as industrial waste tires, motorcycle tires, etc., and has strong adaptability.

7. Product diversification: Through different processing techniques, recycled rubber can be used to produce a variety of products such as recycled rubber, rubber particles, asphalt, etc., which have a wide market demand.

8. Reasonable plan: The plan can be modified and designed according to customer needs to meet the customer’s actual production projects.

Product Parameters

| Production line configuration | Machine configuration | Capacity(kg/h) | Discharging |

| Tire cutting production line | Tire shredder/fully automatic tire block breaker | 1000-3000 | 50-100mm Rubber Block |

| Tire granulation production line | Tire shredder, wire separator, rubber granulator, magnetic separator, vibrating screen, fiber separator | 500-8000 | 3/3-5/15-20mm Rubber Granules |

| Tire grinding production line | Tire shredder, double-roll rubber breaker, vibrating screen, magnetic separator | 500-3000 | 30-80 mesh Rubber powder |

Have you decided on the model you want to buy? If you can’t find the model you want, please contact us for consultation.

More related cases

The waste tire recycling equipment produced by Henan Reacore can not only recycle the rubber in waste tires, but also recycle the steel wire, fiber and other materials in them. The equipment reduces environmental pollution and improves resource utilization. Its secondary production of high-utilization value products is widely used in multiple industries such as construction, environmental protection, and rubber processing.

Why Choose Us

We have a professional team of engineers who can design and manufacture production solutions according to your needs.

We have a professional modern production workshop, and all the equipment leaving the factory has been quality inspected.

We have many years of manufacturing experience, all equipment is independently developed and produced, the price is more favorable.

We provide a full range of technical support and can provide you with high-quality purchasing services and after-sales services.

More related products you may want to know

contact us for quote

You can tell us your needs from the following aspects:

1. What is the product name and model you want to know?

2. What type of project do you plan to buy our equipment for?

3. When will you start this project?

4. Where will you carry out your project?

If you don’t know how to choose a specific product, or you need a special project design solution, you can leave your contact information and our technical engineers will design a special solution for you.