With the strict requirements of environmental protection, the recycling of waste tires has gradually become a focus of global attention. As an industry-leading environmental protection equipment manufacturer, Henan Recore has developed a variety of waste tire recycling line. It can efficiently and greenly process waste tires and convert them into valuable resources. The following are the three main types of waste tire recycling lines produced by Henan Recore:

1. Fully automatic block cutting line for waste tires

The fully automatic block cutting line is a highly efficient equipment designed for the treatment of waste tires. Its core function is to cut the entire tire into regular small pieces for subsequent processing and utilization.

- Working principle: Through automated mechanical cutting technology, the tire is accurately divided into rubber blocks of specified sizes. This cutting method is both efficient and safe, and can maximize the original performance of the rubber.

- Advantages: The fully automatic block cutting line is simple to operate, stable in operation, and suitable for tire pretreatment. The cut rubber blocks can be used in the fields of recycled rubber production, rubber powder processing, etc., with high recycling value.

- Application scenarios: Suitable for tire dismantling companies, recycling resource processing plants and large-scale environmental protection projects.

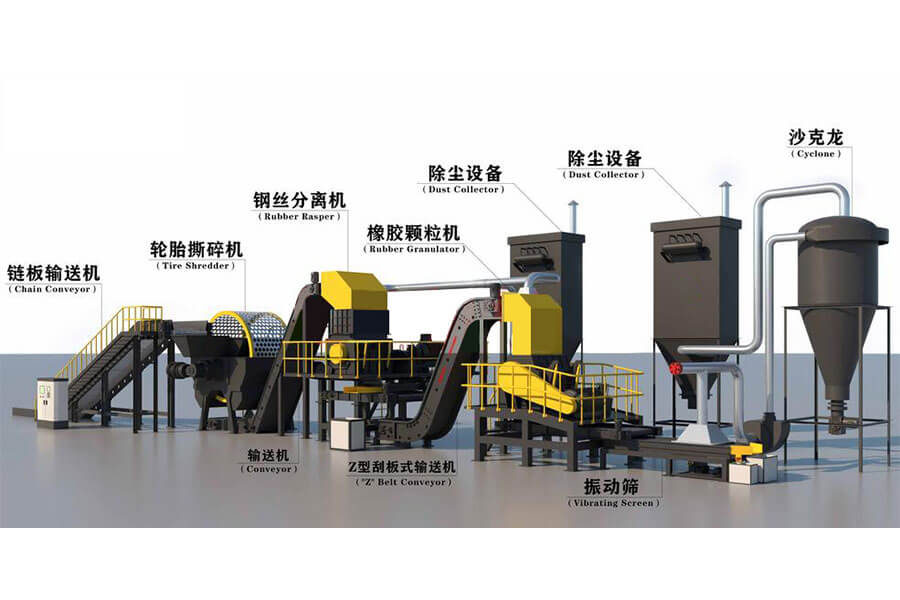

2. Waste tire granule production line

The granule production line is one of the important equipment for waste tire recycling. It can further process the cut rubber blocks into fine tire particles. These particles have broad application prospects in many fields due to their excellent physical properties.

- Working principle: Through crushing, screening and other processes, the granule production line makes rubber blocks into tire particles of different particle sizes (usually 3-20mm). In this process, the equipment will automatically separate the steel wire and fiber to ensure the purity of the final product.

- Advantages: The granule product has uniform particle size and good fluidity, and can be directly used in rubber product production, asphalt modification and other fields. In addition, the granule production line has a high degree of automation, low energy consumption and low operating cost.

- Application scenario: Suitable for tire recycling companies, asphalt mixing plants and rubber product processing plants.

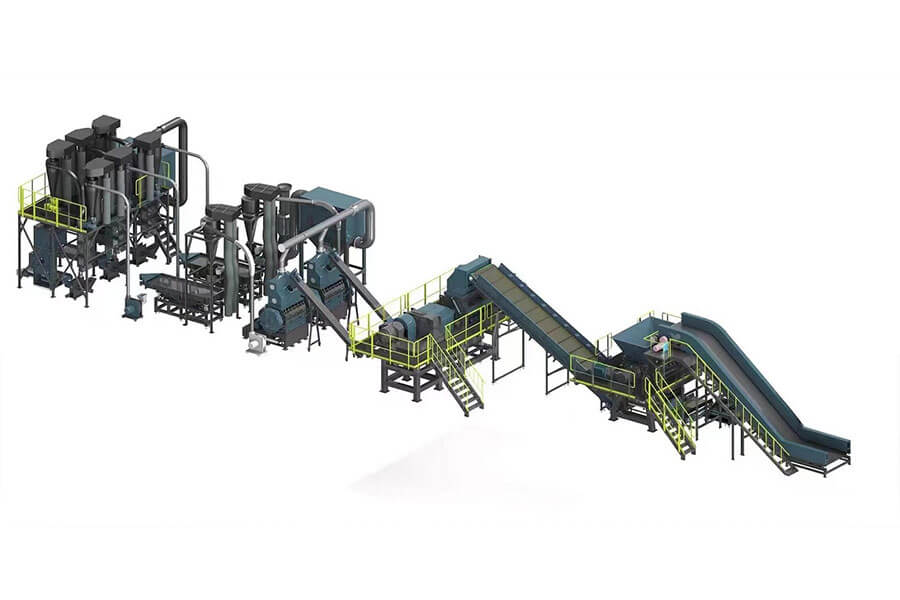

3. Waste tire rubber powder production line

The rubber powder production line is a more sophisticated equipment used to make waste tires into fine rubber powder particles (usually 20-100 mesh). Compared with granule products, rubber powder has a wider range of uses and higher added value.

- Working principle: The rubber powder production line adopts advanced micro-crushing technology to process rubber blocks or particles into fine rubber powder in the processes of crushing, screening and grading. In this process, the equipment removes steel wire and other impurities by physical separation.

- Advantages: Rubber powder has high elasticity and good wear resistance, and is widely used in rubber product modification, asphalt pavement paving, and industrial sealing materials. In addition, the energy consumption in the production process of rubber powder is low, and the environmental protection performance is excellent.

- Application scenario: Suitable for high-end rubber product companies, asphalt pavement construction units, and waste tire resource utilization projects.

Conclusion: The value and prospects of Henan Recore’s waste tire recycling line

The three waste tire recycling lines produced by Henan Recore (fully automatic cutting line, particle production line and rubber powder production line) represent the highest level of current waste tire processing technology. They can not only efficiently convert waste tires into high-value-added products, but also make great contributions to environmental protection and social development.

As the world’s attention to environmental issues continues to increase, the application prospects of these equipment will be broader and become an important force in promoting the circular economy! If your company is looking for an efficient waste tire recycling solution, Henan Recore is undoubtedly a trustworthy choice. Contact us for quote!